Mooring is an integral part of cargo transportation. During the mooring period, the ship faces various natural forces and human forces. The mooring system refers to the use of the device to fix the ship at the wharf or other places to limit its movement. There are five common mooring equipment that are essential.

Mooring Bollard

Explanation And Categories

The mooring bollard is mooring ship equipment installed in the superstructure of the wharf. It is designed and selected according to the berth capacity and wharf structure type to meet the requirements of the safe, reliable, and convenient operation of ships leaving the wharf, berthing, shifting, and turning. It is composed of a shell, anchor rod, nut, washer, anchor plate, and column core packing. The most common types in the shipping industry are column mooring bollards and cruciform bollards.

The mooring bollard material is divided into cast iron (HT200), ductile cast iron QT450-10, and cast steel (zg230-450), and the specification and model are 50kn-2000kn.

According to the purpose, there are general bollards, storm bollards, test bollards, etc.

According to the shape, it is divided into T head bollard, twin horn bollard, single bitt bollard, double bitt bollard, and kidney bollard.

How To Choose The Mooring Bollard

- For the selection of mooring bollards, attention shall be paid to the requirements of the specification and size. Because of the different specifications and sizes of the ships, there are certain restrictions on the device.

- Attention shall be paid to the restrictions on the installation position to avoid problems in the installation.

- Attention shall be paid to the installation requirements, especially the power restrictions, to ensure that the installation of the device meets the stability requirements and ensures the effect.

- It is necessary to pay attention to the functional requirements and functional limitations, especially the functional requirements of the cable and the limit of the bearing capacity, to ensure the stability of the device in use.

Mooring Chock

Explanation And Categories

Mooring Chock is a closed-hole fairlead that is arranged on the bulwark and used to limit the leading out of the position of the cable. The basic shapes are round, oval, square, and closed mooring chock.

204 steel seamless steel pipe specified in GB 8162 is selected as the material of its body. It can also be bent from grade a steel plate specified in GB 712. 1Cr18Ni9Ti stainless steel plate specified in GB 4237 is selected as the stainless steel clad plate. At the intersection line of the body and the outer edge, the welding surface shall be clean and free of cracks, warpage, and skew. The cutting shall be straight and the sharp edge shall be removed. The stainless steel clad plate shall be flat with the body, and the weld shall be free of defects such as pores, cracks, and burrs.

How To Choose The Mooring Chock

- Corresponding types: Different types of products have different structural shapes. We need to choose the corresponding type chock to be able to use normally because of the appropriate structural shape.

- Corresponding models: There are different models of the same type of mooring chocks, and there are certain differences in decoupling strands and materials between different models of it. Based on this situation, we need to select the corresponding model of products to be applicable.

- High precision: Because the application has high requirements on the structure and quality of the mooring chock, it needs products with high precision, which will have better applicability because of the excellent comprehensive quality.

Roller Fairlead

Explanation And Categories

Roller fairlead is a fairlead composed of several independent rollers in parallel, which can be divided into the closed type and open type.

According to the number of rollers, the commonly used two-roller, three-roller, and four-roller fairleads. It can export several cables at the same time, and its mass is smaller than that of the fairlead with rollers. It is mainly used on large and medium ships.

How To Choose The Roller Fairlead

- When selecting, it is necessary to see whether the surface of the device in contact with the cable is smooth. To avoid large abrasion of the cable during use, which may lead to the cable being easily broken and unable to be used for a long time, it is required to pay attention to whether the surface contact with the cable is sufficiently clean when selecting the guide roller.

- Observe the steel parts except for the body and pin shaft. Generally speaking, there is no problem with the fairlead roller in the body and pin shaft structure. Therefore, it is suggested that when selecting the device, we should focus on other steel parts, especially paying attention to whether the steel parts other than the body and pin shaft have been galvanized or painted.

Rubber Fender

Explanation And Categories

Rubber fender is installed on the wharf or ship to absorb the collision energy between the ship and the wharf or ship when berthing or mooring, and protect the ship and the wharf from damage.

It is divided into the following categories: cylindrical rubber fender, DA type rubber fender, D type super arch rubber fender, drum type rubber fender, DO type rubber fender, and V type rubber fender. They are different in reaction force, surface pressure, device maintenance, and convenience of use.

How To Choose The Rubber Fender?

Before purchasing, we should consider the brand issue. Not all products have no difference. Products with good brands can be guaranteed.

When purchasing, pay attention to whether there is damage, and select complete and pollution-free ones; When using in the later stage, pay attention to the placement position and do not place it at will.

Do not use sharp objects to cause damage to the wharf fender; For rubber products, avoid direct sunlight and chemical corrosion; Check regularly and replace it immediately in case of any problem.

Marine Anchor

Explanation And Categories

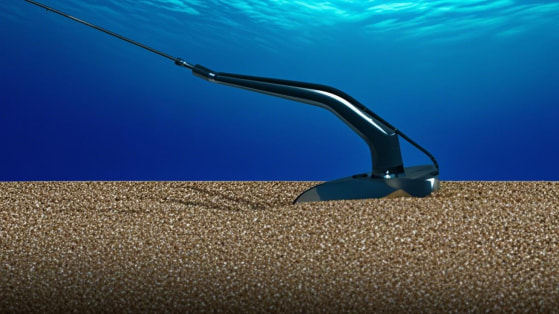

The main function of the marine anchor is to fix and stabilize the ship. After the anchor is pulled into the water bottom, it can provide berthing capacity for the ship. It should be noted that this capability is not only accomplished by one anchor, but also by a long anchor chain.

There are many types of anchors, which can be divided into rod anchors (also known as naval anchors), Rodless anchors (commonly known as hall anchors and Speke anchors), high grip anchors (generally rod rotating claw anchors), and special anchors (commonly used for permanent mooring) according to different structural solutions and uses.

How To Choose The Marine Anchor?

There are many choices for marine anchors. They are made of different materials.

- Bruce claw anchor is one of the most popular anchors among leisure rowers in North America. For most rowers, Bruce or delta is the best balance between price and performance.

- Plow anchors are suitable for most bow rollers. Fluke anchors are the perfect choice for auxiliary anchors or stern anchors. They perform well in sediment and can be easily stored on most bow rollers.

- The head anchor of commercial ships mainly adopts stockless anchors, and the tail anchor sometimes adopts stocked anchors and dovetail anchors.

- There are many types of anchor materials, the most popular are low-carbon steel, high-strength steel, stainless steel, and aluminum. Most of the traditional steel anchors we are used to seeing in the market may be low-carbon steel or high-strength steel. When selecting ship anchors, in addition to the factors such as the length and weight of the ship, it is also necessary to carefully select the anchor materials.

Summary

The mooring system refers to the use of equipment to fix the ship at the wharf or other places to limit its movement. This paper introduces the definition, classification, and selection skills of different berthing equipment.