1. What are dredging pipeline floaters?

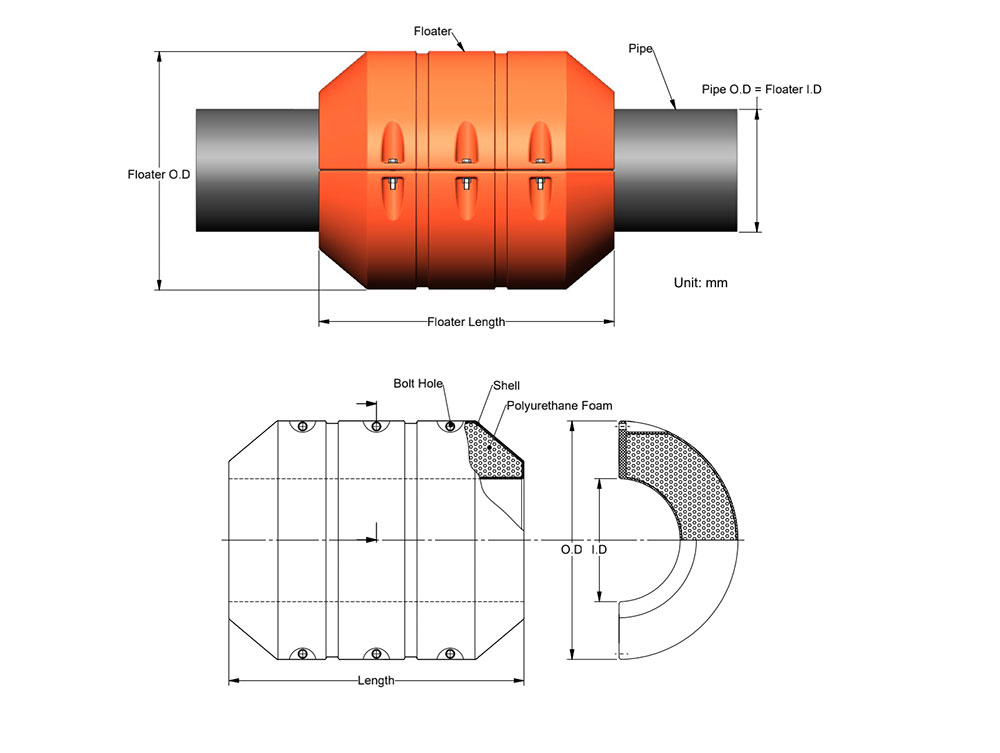

Dredging pipeline floater is a lightweight foam-filled or inflated float used to support hoses and cables on the surface of a waterway. They compress fit around pipes, hoses or cables and are designed to prevent hoses and cables from sinking below the surface of the water. They are easy to install, UV resistant, brightly colored and easy to spot, making them ideal for dredging, mining, marine and any other application that involves getting work done on waterways.

2. Benefits of dredging pipeline floaters

Dredging pipeline floats are made of corrosion-resistant and UV-resistant materials that can withstand waves, wind and the impact of ships. There are many advantages to using them:

- Lightweight design

High-density, lightweight material facilitates transportation and installation. This is especially valuable when regular mobile operations are required.

- UV and corrosion resistant

Constructed from thickened PE material, our pipe floats stand the test of time whether in marine environments or in harsh conditions, reducing the need for downtime for replacements.

- Easy to install and maintain

Two pairs of tube floats are a group, and two pieces are a pair. The two halves of the pipe float are easily connected by bolts/nuts made of galvanized steel (or stainless steel if required). Plus, keeping pipes, hoses and cables afloat makes it easier to spot any maintenance issues and streamline repairs.

- High visibility and good security

Dredging pipeline floaters are often made in bright colors and serve as warning signs to other nearby vessels. High visibility and impact-resistant construction help reduce safety concerns.

- Impact and abrasion resistant construction

The interior adopts environmentally friendly PU filler, which has excellent impact resistance and can withstand rough seas and ship collisions.

- Environmental friendly

Dredging pipeline floaters help protect the bottom of bodies of water through which pipes, hoses or cables pass, preventing any environmental damage.

3. What is the main application of the dredging pipeline floaters?

Dredging pipeline floaters are valuable in a variety of applications and are designed to meet the needs and changes of their respective environments from mining to construction, aquaculture to oil and gas. For example, floats for fuel lines, hoses, and cables are not the same design as floats for larger pipe diameters. At Boomarine, we can custom float designs for all types of applications. Here are some examples of applications that can benefit from the value of dredging pipeline floaters:

- Used for mining pipelines to float on the surface of rivers, waterways, dams, ports, etc.

- Used for sand mining, dredging, estuary dredging, tidal flat water replenishment.

- Used in large-scale land reclamation and other civil engineering projects.

4. How to determine how many dredging pipeline floaters are needed?

The quantity requirements of dredging pipeline floaters will vary depending on the environment and scale of use. Therefore, when considering the actual quantity requirements, there are often many factors that need to be calculated, and the following information needs to be collected:

- Nominal pipe size.

- Rate the SDR (Standard Dimension Ratio) of the pipe.

- The density of the material flowing through the hose or pipe.

- Establish desired submergence level (50% to 80% submerged).

- The length of hose or pipe you need to float.

- Whether the product will be used under freezing conditions.

The spacing between each dredging pipeline floater varies by application, so additional details may be required. Keep in mind that insufficient or inconsistent spacing of floats can cause variations in pipe or hose immersion, which can actually restrict the flow of material within the pipe, slowing it down. Another factor to consider is the viscosity and specific gravity of the fluid. Some fluids may be heavier than others, which increases the number of dredging pipe floats needed to avoid submersion.

5. How to choose suitable dredging pipeline floaters?

Polyethylene floats are commonly used in the world for dredging projects and land reclamation projects. They are the ideal floating material for dredging pipelines.

When choosing a pipe float, we must know the following points:

- Buoyancy: Usually the buoyancy needs to be 30% higher than the pipeline counterweight (including 1.3 ration mud). When the pipeline is working, the float should be about 1/4 of the height of the steel pipe above the water surface.

- Weight: not less than 3-5% of the ordered goods. The weight of the float is related to the weight of the hull and the density and volume of the foam. The foam density should be approximately 35kg/m³.

- Plasticized strength: The surface of the float after plasticization is smooth and smooth, without obvious particles, and the tensile strength is the best.

- Foam density: about 35kg/m³, tensile strength 0.2Mpa. A little springy, not sticky or brittle. A float with these properties will be the best and most durable float.

Summary

Dredging pipeline floaters have their respective values in various applications. You may also encounter a variety of problems in the selection and use of dredged pipe floats. As an expert in offshore equipment, Boomarine can provide you with professional references to solve your various problems before and after the sale.