Ship launching airbags also known as inflatable boat airbags, roller bags, empty bags, life-saving bags, are long cylindrical balloon shapes, which are made of heavy-duty synthetic wheels and internal and external rubber layers. It is made of rubber with synthetic wheel curtain lines, widely used in ship launching or landing, heavy lifting and conveying, sunken ship salvage, and stranded ship saving.

These ship launching airbags are rugged enough, usually have a long service life, which can be up to 15 years in the case of reasonable maintenance. However, it will inevitably be punctured by some neglected sharp objects. At this time, it is very necessary to repair the marine airbags correctly. Good maintenance can restore the entire performance of airbags. This article will introduce how to repair damaged ship launching airbags, as well as usual maintenance.

There are a total of 5 steps to repair damaged ship launching airbags, but before repairing, you need to prepare the tools and materials required for repair.

Repair Tools:

- Angle Grinder – Grinding the incision on the airbag.

- Brush – Patch and cut glue brush on the ship launching airbag.

- Hydraulic Jack – Press the rubber sheet to heat the heating plate.

- Steel Plates and Blocks – In order to press the hydraulic jack to press the heating plate with rubber blocks. Steel plate needs to be placed on the heating plate.

- Bracket – To enable hydraulic jacks to press the heating plate with rubber patches.

- Large Needle with Cords – Sew the cut with cords.

- Sandbag – Place sandbags between marine airbags and brackets.

- Heating Plate – Heating patch, vulcanized incision.

Repair Materials:

Surface rubber, cord rubber sheets, glue rubber, isolating cloth

Repair Steps

1. Clean the surface of airbags

When you are ready to repair airbags, you must clean up the airbag’s surface to make sure there is no sand or oil on it. Then dry and put it in a clean place. Make sure that do not immerse the airbag into the water for more than 10 minutes before repair.

2. Check and mark the damaged area

Mark the repair area of airbags, which must be expanded from center to outside (20-26cm) and remember that do not ignore the hiding damaged areas. Note: the expansive range depends on the size of damaged areas.

3. Repair

- Wear the surface of the damaged area until the cord showed and do not damage the cord layer.

- For some long cracks, it needs to use needle and cord layer to suture, sewing needle positioned about 2-3 cm away from crack, with about 10cm distance between stitches.

- Wash the surface of repair part with gasoline and dry it.

- Brush up some special glue on repair part, which is made of raw rubber material with gasoline mixture together. The ration of raw rubber material gasoline is 1:8, then dry it again.

- Prepare the repair rubber material and the repair material should be the same as the airbags. Meanwhile, the structure layers 2-6 will be based on the size of damaged area. Seal the leakage area using a pure rubber belt of 1mm thickness, the belt width and length should be more than 1cm around the crack.

- Put the layers on the damaged area. The first layer of interleaving is ordinated, the second layer of interleaving is biased. The angle should be the same as the airbag, and it should be 20mm bigger than the first layer. The third layer is also biased, the angle should be contrary to the second layer. It also needs 20mm bigger than the second layer. From 4-layer to 6-layer keeps the same steps. Circular angle should be required by interleaving and the semi-diameter should be 40-50mm.

4. Thermal vulcanization process

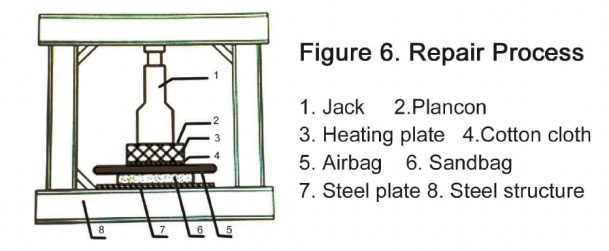

Using a simple working structure (figure 6) to vulcanize the damaged areas.

During the process of vulcanization, please remember to control the temperature up to 150±5 degrees and push pressure to that using jack. Then close the heat steel plate and permit it to cool very slowly to 60 degrees during this time, don’t remove the jacket.

5. Inspection

Check the repair area to make sure that no leakage on it. Finally, inflate it and make a pressure test.

Maintenance of ship launching airbags:

Marine airbags can be reused, and the correct use methods and reasonable storage can extend their service life.

- Strictly control pneumatic pressure, do not exceed the upper limit of work pressure.

- Adopting contact with sharp objects during use, such as a steel nail, welding slag.

- When transported, the movement should be rolled or moved under natural conditions, which is strictly forbidden to drag on the ground.

- When the ship launching airbag is not used for a long time, it should be cleaned, cover, and fill the talc. And then placed it in a dry, cool and ventilated place, and stay away from the fire.

The above is the repair and maintenance of ship launching airbags. If you still have something you don’t understand, please feel free to contact us. Boomarine is a professional marine equipment supplier, we can offer high-quality marine fenders. Besides, we can also provide customers with a range of customization solutions.