What is the marine bollard strength test?

Marine bollard pull is a test, or rather the result returned by a test, to determine the maximum pull that a working vessel can apply. There are two ways to establish these values: actual experiments and simulations. Practical trials consisted of physically attaching the measurement device to the boat and stationary objects, and reading the resulting force while the boat was under full thrust. The simulation results are entirely based on calculations performed on complex software. Actual experiments are not always accurate due to the large number of peripheral conditions that affect the results, while simulations are expensive and are usually only used by large shipping companies.

Determining the tractive effort of a ship (especially a tugboat) is more complicated than calculating the horsepower of a land vehicle. There are a number of factors, such as different propulsion systems, transmission types and associated efficiency losses, that make the output values using power plants inaccurate. Bollard pull tests return more realistic and representative results and are widely used to determine working vessel pull values.

What are the methods of marine bollard strength tests?

Bollard pull values can be achieved in one of 2 ways – through simulation or actual testing.

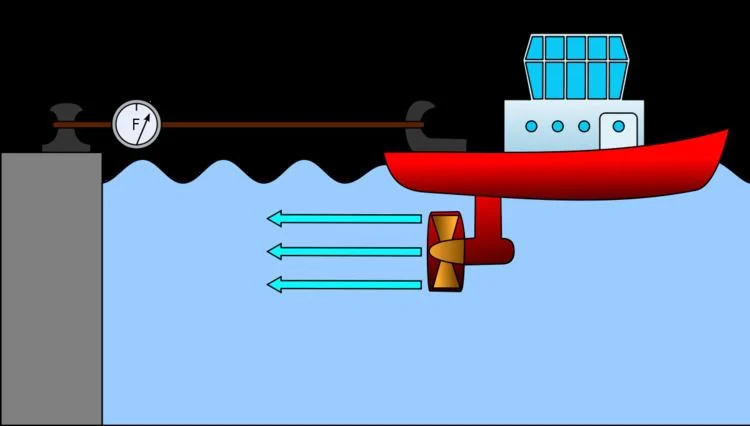

The actual test consisted of suspending the strain gauge from a marine cable, which was attached to a stationary object at one end and to the test boat at the other end. Mooring bollards are often used as anchor points, which is the name of the test. When the boat’s engines are applying maximum thrust, the pulling force exerted on the cable is read from the gauges. This is the cheaper of the two methods and is commonly used by smaller boat builders to test disposable vessels. However, this type of bollard test is difficult to perform accurately because many critical boundary conditions need to be satisfied before results can be determined.

These factors include using a deep, undisturbed body of water free of strong winds and currents to conduct the experiment. Thrust must also be generated by the ship’s propeller alone, not assisted by the rebound force generated by adjacent obstacles. The propeller’s tendency to walk or the propeller to yaw the boat to one side must also be accounted for in the equation. The relationship between bollard height and vessel cleat height and streamer geometry are also important factors. Even the salinity or salt content of seawater can affect the accurate measurement of bollard pull values.

Simulated bollard pull tests are simpler to perform, but are much more expensive than actual tests. These are purely mathematical calculations performed by highly sophisticated and accurate ocean simulation software. The high cost of simulating bollard pull tests makes them more suitable for large shipyards producing ship production lines. However, simulated tensile tests, while accurate, are usually backed up by actual test results.