What is frontal panel?

The frontal panel is an important part of many types of rubber fender systems. It is mainly used in conjunction with super cell fenders, super cone fenders, leg fenders, etc., which can increase the contact area between the fender and the ship and reduce the surface pressure.

Each frontal panel is designed for specific berth needs. The design will depend on a combination of factors including dock and vessel type, berthing style, fender arrangement, hydrological conditions, etc.

What is the structure of frontal panel?

There are 2 types of structure: open type and closed type. Regarding the open type, it consists of steel pad, H steel, and across steel. The closed type consists of steel pad, back steel, and H steel.

Design requirements of frontal panel

The function of the frontal panel is to distribute the reaction forces from the fender units into the ship’s hull, so the design should suit each individual berth. The loads and stress loads exerted on the front panel will depend on many factors – the type of ship, berthing mode, characteristics of the rubber fender, and tidal range, etc. It should be designed for different applications and conditions, taking into account many of the following factors:

- Type and size of rubber fenders;

- Introduce bevel and chamfer;

- There is no deflection on the front panel and face pad during the compression.

- Rubber fender reaction force and connection;

- Hull stress and tidal range;

- Resistance to impact on part;

- Resistance to bending moments and shear forces?

- Local buckling;

- Load factor at limit state;

- Steel grade;

- Welding process;

- Fatigue strength;

- Asymmetric loading effect;

- Suitable corrosion protection for the intended environment?

- Anti-corrosion protection;

- Service life.

The Design determinations of the structural dimension of frontal panel

The design should meet the following requirements

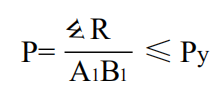

- Py= hull allowable surface pressure (KN/m2)

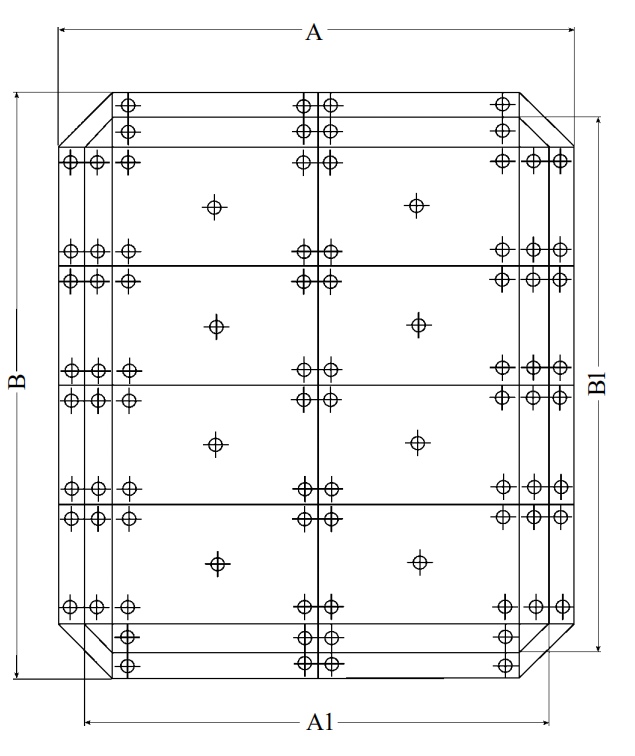

- B1= valid length of the front panel (m)

- A1= valid width of the front panel (m)

- WR = the sum of max. the reaction force of all fender (KN)

- Where P= Hull Pressure

Therefore if the allowable surface is known, the dimension of the frontal panel can be determined.

The allowed hull pressure can be obtained from the following table if it’s not available in the design.

| Ship Pattern | Allowed Hull Pressure |

|---|---|

| Greneal oil tanker | 250-350 KN/m2 |

| Coastal tanker | 150-250 KN/m2 |

| Bulk ship | 150-250 KN/m2 |

| Panamax container ship | 300-400 KN/m2 |

| Sub-panamax container ship | 400-500 KN/m2 |

| General cargo ship | 300-600 KN/m2 |

| Gas carrier | 100-200 KN/m2 |