Horizontal Sheave Fairlead

- Product Code: AE3500

- Material: High tensile steel

- Wire Size Range: 25mm to 64mm

- Warp Angle: 90°~180°

- SWL: 234kN to 1414kN

- Weight: 176KG to 1300KG

- Installation Method: Weld Down/Bolt Down

- Mounted Position: Deck

- Surface Treatment: Sandblasting then painted epoxy or according to the customer’s request.

- Certificate: CCS, ABS, LR, BV, NK, GL, etc.

The Horizontal Sheave Fairlead also known as Horizontal Guide Deck Sheave Fairlead, is a critical component for marine applications. It is a high-performance, durable component designed to guide and manage ropes, cables, and wire ropes, minimizing wear and tear during heavy-duty operations. It is crafted from premium materials like corrosion-resistant alloys and stainless steel to ensure maximum durability and performance, even in the most challenging environments. The sheave’s horizontal orientation provides superior alignment, reducing friction and prolonging the life of the rope or cable.

The Horizontal Sheave Fairlead is an indispensable component for industries requiring efficient and reliable rope or cable management. Offering enhanced durability, reduced wear, and superior performance under high loads, it ensures that your equipment runs smoothly, safely, and with minimal maintenance. Whether for marine, industrial, or construction purposes, this fairlead is engineered to handle the toughest tasks with ease.

At Boomarine, we are dedicated to providing high-quality, durable, and reliable components for industries that require advanced cable and rope management solutions. With years of expertise in designing and manufacturing precision-engineered products, we specialize in the production of essential components like the Roller Fairleads. Our mission is to enhance the safety, efficiency, and longevity of your operations by delivering innovative solutions that meet the toughest demands in various industrial, marine, and construction applications.

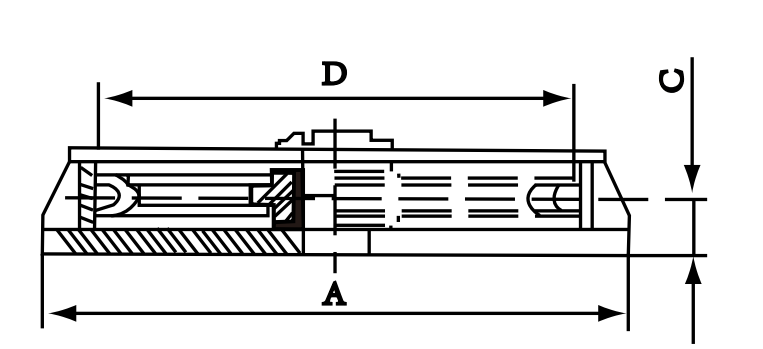

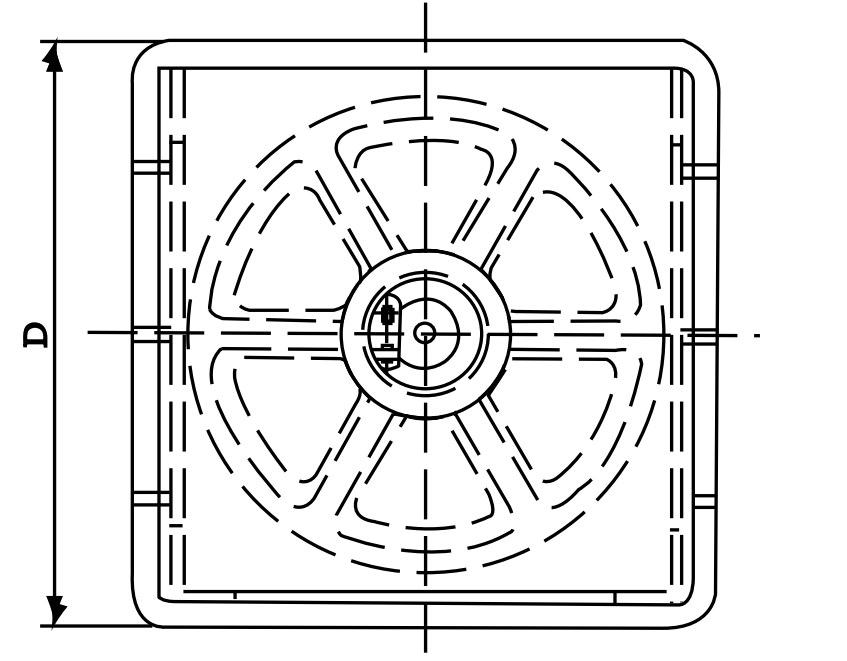

Parameters of Horizontal Sheave Fairlead

| Wire Size | Sheave Dia D(mm) | Dimensions(mm) | SWL (KN) | Mass (Kgs) | |||

| (mm) | (Inch) | A | A | A | |||

| 25 | 1 | 406 | 635 | 635 | 71 | 234 | 176 |

| 32 | 1-1/4 | 508 | 780 | 780 | 85 | 355 | 270 |

| 38 | 1-1/2 | 610 | 914 | 914 | 100 | 500 | 425 |

| 45 | 1-3/4 | 660 | 845 | 845 | 110 | 671 | 560 |

| 52 | 2 | 762 | 1143 | 1143 | 120 | 935 | 890 |

| 64 | 2-1/2 | 914 | 1130 | 1130 | 130 | 1414 | 1300 |

Remark:

- Build to withstand breaking stength of indicated rope at 90°

- Wrap angle: 90°-180°

- Sealed roller bearing

- Option: a. with Load pin(Exd Proof); b. with Horizontal Roller.

- For offshore Purpose

Features of Horizontal Sheave Fairlead

- Robust Construction: Made from corrosion-resistant materials like stainless steel or durable alloys, ideal for harsh environments, ensuring longevity and reliability.

- Smooth Operation: Precision-engineered sheaves allow smooth and controlled movement of cables, reducing friction and cable wear.

- Versatile Compatibility: Compatible with a wide range of rope sizes and types, making it adaptable to various systems.

- Weather Resistant: Built to withstand extreme weather conditions, including saltwater exposure and extreme temperatures, for marine and outdoor applications.

- Low Maintenance: Durable construction and high-quality bearings reduce the need for frequent maintenance and upkeep.

- Easy Installation: Designed for straightforward installation in a variety of configurations, whether on machinery or structural frameworks.

- Improved Efficiency: Smooth line handling enhances overall system efficiency and reduces the risk of line jams or breakage.

Marine Applications of Horizontal Sheave Fairlead:

- Mooring systems for boats and ships

- Anchor handling systems

- Towing operations

- Fishing vessels

- Offshore platforms

Ideal for use on boats, ships, and offshore oil rigs, where ropes and cables need to be safely managed under high-stress conditions.

Why Choose Our Company for Horizontal Sheave Fairlead?

When it comes to critical components like the Horizontal Sheave Fairlead, choosing the right supplier is crucial to ensuring optimal performance, safety, and long-term reliability.

1. Uncompromising Quality & Durability

Our Horizontal Sheave Fairlead is engineered with the highest standards of material quality, including corrosion-resistant stainless steel and robust alloys. We ensure that each product is built to endure harsh environments, from salty marine conditions to extreme industrial environments. This durability ensures that your equipment operates smoothly without frequent maintenance or replacement.

2. Customizable & Versatile

Our Horizontal Sheave Fairlead is versatile, accommodating a wide range of rope sizes and types. We can customize the design to suit the specific specifications of your system, whether it’s for light-duty operations or high-load applications. This flexibility ensures that you get the right solution for your needs, without the limitations of a one-size-fits-all product.

3. Competitive Pricing Without Compromising Quality

While our products are built to the highest standards of durability and performance, we offer competitive pricing to ensure that our customers get the best value for their investment. Our fairlead solutions are designed to provide long-term cost savings by reducing maintenance costs, minimizing downtime, and enhancing the longevity of your ropes and cables.

4. Expert Support and Service

We pride ourselves on offering exceptional customer service, from initial consultation to post-purchase support. Our team of experts is always available to answer questions, offer technical advice, and assist with installation or maintenance guidance. We are dedicated to ensuring that our Horizontal Sheave Fairlead delivers the performance you need, with ongoing support to help you get the most out of your investment.