Rubber fender is an indispensable component of marine equipment. Correctly sizing rubber fenders ensures that the marine structure (both the vessel and the dock) performs optimally under impact conditions. It minimizes damage to both, ensures safety for crew and cargo, and enhances the efficiency of docking operations. By investing in the right fender size, operators can maximize operational lifespan, minimize risks, and improve the overall safety and performance of their fleet.

Factors Influencing Rubber Fender Size

When calculating the correct size of a rubber fender, several key factors must be considered to ensure that the fender will perform optimally under different conditions. Incorrect sizing can lead to damage to both the vessel and the dock, higher maintenance costs, and increased operational risks. Below is a detailed description of the factors influencing rubber fender size:

1. Vessel Size and Type

The type and size of the vessel have the most significant impact on the rubber fender’s dimensions. The fender must be capable of absorbing the energy generated by the vessel’s mass, speed, and type during docking.

- Vessel Weight and Length:

Larger vessels, such as cargo ships, tankers, or container vessels, generate more force when they make contact with the dock due to their higher weight. This requires a larger fender with a higher energy absorption capacity.

For smaller vessels, such as yachts or fishing boats, smaller fenders will suffice, as they exert less force upon impact. However, even small vessels can benefit from properly sized fenders, as inadequate protection can lead to hull damage and dock wear.

- Vessel Type:

Different vessel types (e.g., tankers, bulk carriers, passenger ships, yachts) may require different fender shapes and sizes, even if they are the same size and weight. For example, tankers or large bulk carriers typically require fenders that can absorb higher energy impacts due to frequent, high-speed docking.

High-speed vessels, such as ferries or naval ships, generate more energy during docking due to their approach speed, requiring fenders that are specifically designed to absorb these dynamic loads.

- Bow or Stern Impact:

The location of impact also affects the fender size. For example, fenders located at the bow or stern of a vessel may need to be larger because these areas typically experience higher forces during docking. In contrast, fenders along the sides may not need to be as large.

2. Berthing Conditions

The conditions in which the fenders are used play a crucial role in determining the appropriate size and type. These include the frequency of impact, the speed of approach, and the environmental conditions around the dock.

- Approach Speed and Impact Energy:

The faster the vessel approaches the dock, the higher the impact energy. This energy is proportional to the square of the speed. The formula for kinetic energy is E=1/2mv2, where m is the mass of the vessel and v is the speed of approach. Faster docking speeds result in much greater forces, which in turn require fenders that can absorb more energy without deforming excessively.

- Frequency of Impact:

The more frequently a vessel docks at a particular location, the more wear and tear the fenders will experience. For high-traffic ports or berths, larger and more durable fenders are required to withstand the constant impact without degrading prematurely. On the other hand, for occasional docking or low-traffic areas, smaller fenders may suffice.

- Impact Angle:

If the vessel docks at a steep angle, more force may be applied to the fender in a concentrated area. Fenders designed to absorb forces at different angles or to allow for angular contact may need to be larger or have a different shape.

- Tidal and Current Conditions:

In areas with strong currents or significant tidal changes, the fender may need to handle additional forces, such as lateral movements or swinging. In such conditions, the fender size must account for these extra stresses to ensure it can absorb not only direct impact forces but also lateral pressures that might occur due to vessel drift.

Basic Formula for Rubber Fender Sizing

When calculating the appropriate size for a rubber fender, there are two primary factors that need to be addressed: Impact Energy and Fender Deflection. The Impact Energy is essential for determining the fender’s energy absorption capacity, while Deflection is necessary to ensure that the fender can compress adequately to absorb the energy without causing undue stress on the vessel or the dock.

1. Impact Energy (kJ)

Impact Energy refers to the kinetic energy generated when a vessel makes contact with a fender during docking. This is a critical factor in sizing rubber fenders because it helps determine how much energy the fender must absorb to prevent damage to both the vessel and the dock.

The formula used to calculate Impact Energy (E) is based on the basic equation for kinetic energy:

E=1/2×mv2

Where:

- E = Impact Energy (in kilojoules, kJ)

- m = Mass of the vessel (in kilograms, kg)

- v = Speed of approach (in meters per second, m/s)

- Explanation of Terms:

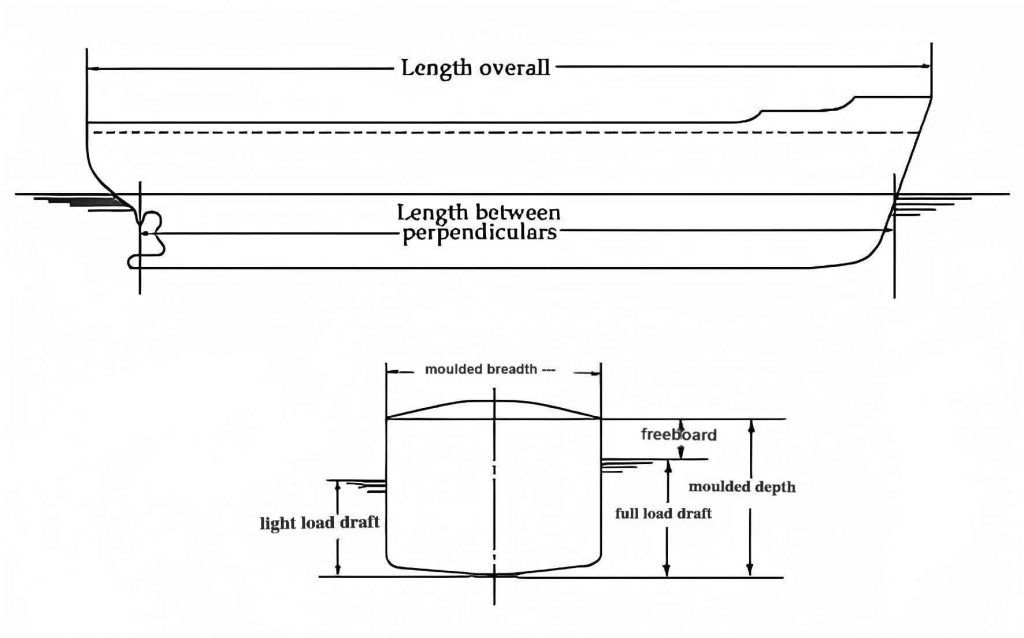

Mass (m): The weight of the vessel is a key factor because a heavier vessel will produce more impact energy when it hits the dock. The mass is typically calculated by multiplying the displacement (volume) of the ship by the density of water, although in practical cases, the weight of the vessel is often provided by the manufacturer or can be found in vessel specifications.

Speed of Approach (v): This is the speed at which the vessel approaches the dock before impact. Higher speeds generate more energy because kinetic energy is proportional to the square of the velocity (v2). This means that small increases in speed can result in significantly higher energy levels. For example, a ship traveling at 2 m/s will generate four times the energy of a ship traveling at 1 m/s.

- Impact of Speed on Energy Absorption:

Higher approach speeds increase the impact energy, which means the fender must have a greater energy absorption capacity. For instance, larger vessels docking at higher speeds (such as ferries or large cargo ships) require larger fenders that can handle the increased energy from the vessel’s speed.

Practical Example: Let’s say we have a vessel with a mass of 50,000 kg (50 tons) approaching the dock at a speed of 2 m/s.

E=1/2×50,000×22=0.5×50,000×4=100,000 Joules=100 kJ

This means the fender needs to absorb 100 kJ of energy to minimize damage during the impact.

2. Fender Deflection

Fender Deflection refers to the degree to which the fender compresses when it absorbs impact energy. When a vessel strikes a fender, the fender undergoes deflection—basically, it squashes or deforms. The amount of deflection that occurs is critical to ensure that the fender absorbs the energy without being damaged itself, while also preventing excessive forces from being transferred to the vessel or the dock.

Ideal Deflection and its Correlation with Fender Size

1) Deflection Limits: The ideal deflection of a rubber fender typically depends on its type and the specific application. For most fenders, the deflection ranges from 20% to 60% of the fender’s original size. For example, if a fender has a diameter of 1 meter, its deflection may be designed to compress between 20 cm and 60 cm under maximum load conditions.

2) Correlation with Fender Size: There is a direct relationship between the size of the fender and the deflection. A larger fender generally has more capacity for deflection because it has a larger surface area and volume of rubber. This allows it to absorb more energy while maintaining lower stress on the materials.

- Smaller Fender: Smaller fenders (such as D-type fenders for yachts) tend to have lower deflection limits (about 20%-30%) and are designed for smaller vessels. These fenders absorb less energy and require less deflection because smaller vessels generate less impact energy.

- Larger Fender: Larger fenders (such as arch or cone fenders for large cargo ships) are designed to handle higher impact energies and have higher deflection limits (around 30%-60%). These fenders must be able to compress significantly to absorb the higher impact energy generated by large vessels.

3) Deflection and Safety: Proper deflection ensures that the fender can spread the energy from the impact across a greater area, reducing the risk of localized stress concentrations on the vessel and dock. It also ensures that the fender does not compress too quickly or too slowly, providing a controlled deceleration of the vessel.

Maximum Allowable Deflection and its Impact on Sizing

1) Maximum Deflection: While deflection is necessary for energy absorption, there is a limit to how much deflection is acceptable before the fender fails or becomes inefficient. This is known as the maximum allowable deflection. If the deflection exceeds this limit, the fender may become permanently deformed, leading to a reduction in performance, premature wear, and potentially failure.

- Too Much Deflection: Excessive deflection can lead to “bottoming out” of the fender, where the fender compresses fully and no longer provides adequate energy absorption. This could result in the vessel coming into direct contact with the dock, causing damage to both the vessel and the dock infrastructure.

- Too Little Deflection: On the other hand, insufficient deflection can result in an undersized fender that doesn’t absorb enough energy. This would cause excessive forces to be transferred to the vessel and dock, increasing the risk of damage and reducing the overall safety of the docking process.

2) Impact on Fender Sizing: To ensure that deflection remains within safe limits while absorbing sufficient energy, fender sizing must take into account:

- The impact energy (as calculated above)

- The material properties of the fender (elasticity, resilience, etc.)

- The desired deflection range for the type of vessel and environment.

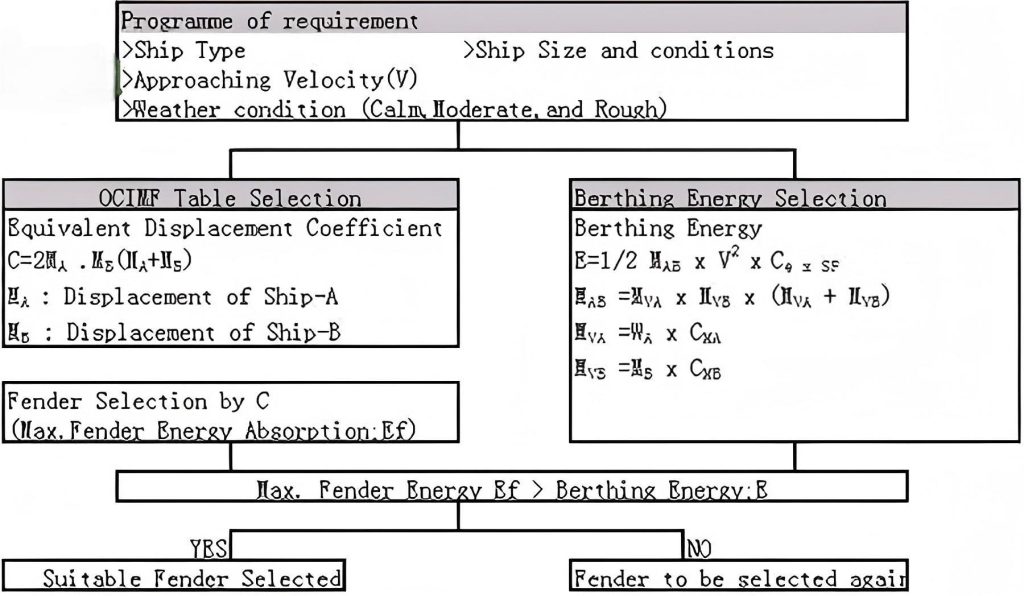

Step-by-Step Calculation Process for Rubber Fender Sizing

A systematic approach is necessary to size a rubber fender properly. This process ensures that the fender provides adequate energy absorption while maintaining the safety and integrity of both the vessel and the dock. Below is a detailed step-by-step calculation process for rubber fender sizing.

Step 1: Assessing Vessel and Berthing Conditions

Before selecting a rubber fender, it’s essential to gather key data about the vessel and berthing conditions.

1.1 Measure or Estimate Vessel Size and Weight

The first step is to determine the characteristics of the vessel that will dock at the berth. This includes:

- Vessel Weight (Mass): This is usually provided in the vessel’s specifications and is expressed in tons or kilograms (kg). It represents the total weight of the vessel.

- Vessel Type: Different types of vessels (e.g., container ships, tankers, ferries) have different berthing requirements. Some vessels may generate higher impact forces due to their shape or weight distribution.

1.2 Determine Impact Energy Based on Vessel Speed and Mass

Step 2: Calculating Required Fender Size

The next step involves selecting the right fender type and determining the amount of energy it needs to absorb.

2.1 Choosing the Right Fender Type Based on Vessel Size and Application

Fender Type Selection: Based on the vessel’s characteristics (size, weight, approach speed), the appropriate fender type needs to be chosen. Different fender types are suitable for different vessels and environmental conditions:

- Arch Fenders: Often used for medium to large-sized vessels with higher energy absorption requirements.

- D-Type Fenders: Typically used for smaller vessels or situations where lower energy absorption is sufficient.

- Cone Fenders: Suitable for larger vessels or high-impact conditions.

- Pneumatic Fenders: Ideal for large ships in high-traffic ports or offshore applications.

The type of fender influences the material and design properties, such as its compression resistance, deflection capacity, and energy absorption limits.

2.2 Using Manufacturer Charts and Guidelines to Match the Required Energy Absorption

Once the fender type is selected, you will need to consult manufacturer charts or guidelines. These charts typically provide recommended fender sizes based on:

- The energy absorption capacity of each fender type.

- The size and weight of the vessel.

- The approach speed and other berthing conditions.

For example, a manufacturer’s chart may suggest that a certain type of cone fender (say, a 2-meter cone fender) is suitable for absorbing up to 150 kJ of energy. If the calculated energy is 100 kJ (as in the above example), this fender would be appropriate.

Manufacturer Chart Example:

- Vessel Weight: 50 tons.

- Speed: 2 m/s.

- Fender Type: Cone fender.

- Energy Absorption Capacity: 100-150 kJ.

The selected fender should have an energy absorption capacity that matches or exceeds the calculated impact energy (100 kJ).

Step 3: Determining Fender Dimensions

Once the appropriate fender type has been chosen and the energy absorption capacity confirmed, the next step is to calculate the fender dimensions (such as diameter, length, and contact area) for optimal performance.

3.1 Diameter and Length of the Fender

The diameter and length of the fender directly affect its energy absorption capacity and deflection characteristics. Larger fenders generally have higher energy absorption capabilities.

- Fender Diameter: A larger diameter fender will absorb more energy because it provides a larger surface area to distribute the force of the impact. The diameter is often selected based on the weight of the vessel and the amount of energy it generates.

- Fender Length: The length of the fender helps to determine how much of the vessel’s hull will be protected during docking. Longer fenders are useful for larger vessels or when the docking process involves larger deflections.

3.2 Calculation of Required Contact Area for Optimal Performance

The contact area refers to the area of the fender that will be in contact with the vessel. It is essential for distributing the impact force across a large area to reduce localized stress and minimize the risk of damage.

Example Calculation:

If a fender needs to absorb 100 kJ of energy, and the expected deflection is 30%, you would use the fender’s energy absorption capacity per unit area and deflection limits to calculate the total contact area. For example, a fender might absorb 10 kJ per square meter at 30% deflection. Therefore, you would need a contact area of approximately 10 m² to absorb 100 kJ.

By following these step-by-step calculations, you can properly size rubber fenders to ensure they provide adequate protection for both the vessel and the dock. Accurate fender sizing will reduce the risk of damage, ensure smooth docking operations, and optimize the overall safety and efficiency of the berthing process.

Conclusion

Accurate rubber fender sizing is crucial for ensuring safe and efficient docking operations. Properly sized fenders protect both the vessel and the dock from the forces generated during impact, which, if not adequately absorbed, could lead to serious damage to both structures. The forces generated during docking can vary significantly based on vessel weight, speed, and type, making precise fender selection essential for minimizing wear and tear.

Choosing the right fender size involves more than just basic calculations—it requires a thorough understanding of the vessel’s characteristics, the berthing conditions, and the specific needs of the docking environment. While manufacturers provide guidelines and charts that assist in the sizing process, factors like vessel speed, weight, docking frequency, and environmental conditions must all be considered.

When in doubt, consulting with a fender manufacturer Boomarine is a good practice to ensure that you’re using the right solution for your specific requirements, avoiding both overdesign and underperformance. Properly selected fenders will provide peace of mind, protect valuable assets, and help ensure the long-term success of your docking operations.