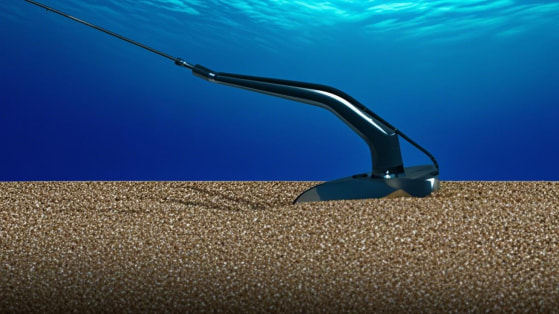

Anchoring system is an indispensable part of marine equipment. When the ship is docked, it is necessary to throw the anchor through the windlass, and the anchor is fixed by the anchor’s grip and the weight of the anchor chain itself, so that the ship can maintain the hull. However, the long-term use of the anchoring system will inevitably lead to various problems. Therefore, the daily inspection and maintenance of anchoring system are very important. This article will introduce how to carry out daily inspections and maintenance of the anchor system.

Testing of Anchoring Systems

Finished anchors should all be inspected, weighed and tested visually without being painted.

1. Appearance Inspection

There should be no cracks, notches, slag inclusions or defects affecting the performance of the anchor on the surface of the finished product, and welding repair is allowed for surface defects that do not affect its strength. The weight of the anchor head (ordinary stockless anchor) (including the weight of the pin shaft and accessories) should not be less than 60% of the total weight of the anchor, and the deviation between the actual weight of the anchor and the nominal weight should be within ±7%.

2. Pulling Test

The stockless anchor pulls two claws at the same time (the test is to be carried out on both sides of the flip); the two anchor claws of the rod anchor are tested separately. The tensile load shall be carried out in accordance with the specifications.

Before the test, marks should be made on the tip of the anchor claw and the anchor rod of the anchor shackle, so as to measure the distance before and after the test; during the test, the tensile force should be added to 10% of the test load, the distance should be measured and recorded, and then the tensile force should be added to the test. 100% of the load, after holding for 5 minutes, gradually reduce the tension to 10% of the test load, measure and record the distance. The residual deformation of the rodless anchor should not exceed 1% of the gauge length, and the anchor claw should be able to flexibly rotate to the maximum designed angle. Rod anchors should have no obvious residual deformation.

3. Grip Test

High holding power anchors and super holding power anchors shall be tested at sea. The holding power of high holding power anchors shall not be less than twice the holding power of ordinary rodless anchors of the same weight; the holding power of super holding power anchors shall not be less than the same weight. 4 times the holding power of ordinary rodless anchors.

4. Test of Anchor Chain

The finished anchor chain is to be subjected to tension and breaking tests as specified in the presence of the surveyor. Paint or anti-corrosion coating shall not be applied to the anchor chain before the test.

5. Tensile Strength Test

In knots, the test shall be carried out on an approved tensile machine according to the specified load, and the elongation shall not exceed 5% and there shall be no obvious defects.

6. Pull-off Test

Choose an anchor chain from each batch of anchor chains with no more than 4 sections, and cut not less than 3 links for testing. If the breaking load is less than the specified breaking load, it is unqualified.

7. Test of Windlass

The windlass shall be capable of twisting a single anchor from 82.5m to 27.5m, and the average anchoring speed shall not be less than 9m/min; the anchor chain shall be released quickly and braked 2-3 times, and the anchor chain shall not slip out or skip the chain on the sprocket. and the phenomenon of unstoppable braking; and after the anchor is dropped, the chain brake should be braked tightly, and the ship should slowly reverse for a while to check the function of the chain brake.

Regular Inspection and Maintenance

Regular inspection and maintenance of anchor system should be carried out at least once every 6 months.

1. Anchor

- Check the wear and deformation of the anchor shackle, and pay attention to whether the cross pin is loose.

- Pay attention to whether the horizontal pin of the anchor head is loose, whether the anchor claw is bent or cracked, whether the rotation is flexible, and whether the angle is normal.

- Check the flexibility of the anchor claw to turn to the maximum angle and the tightness of the fit with the ship’s side.

- When lifting the anchor, after the anchor comes out of the water, observe whether there is any debris hanging on the mooring claw, and slow down the twisting speed, so that the mooring claw can stick to the ship’s side stably at last.

- During ship repair and inspection, the weight loss of the anchor shall not exceed 20% of the original anchor weight.

- When the anchor is found to be damaged, it should be sent to the factory for repair, and the spare anchor should be replaced.

2. Anchor Chain

- Pour out all the anchor chains from the chain locker and arrange them on the deck to remove sludge, rust and paint.

- Crack inspection: Hit each chain link and shackle with a hammer to see if the sound is crisp.

- Deformation check: measure the length of the chain link and shackle. The length of the chain link with gear exceeds 7% of the original length, and the chain link without gear or shackle exceeding 8% of the original length can no longer be used.

- Wear inspection: check the contact between the ring and the ring and the friction between the anchor chain and the anchor chain drum, measure the maximum and minimum diameters of the same section with a caliper, and take the average value. In the Class I navigation area, if the diameter of the chain link is found to be less than 88% of the original specified diameter, it should be replaced. 85% of Class II and III flight areas should be replaced.

- Structural loosening inspection: Check whether the crosspiece is loose, whether the pin connecting the chain link and the shackle is loose, and whether the lead seal is falling off.

- When the ship is repaired and inspected, all the connecting links (shackles) shall be disassembled, and the pins and lead seals shall be replaced. Swap the anchor link and the terminal link and make a record. During maintenance, the anchor chain is simmered to eliminate small scars and internal stress.

- After the inspection of the anchor chain, asphalt paint should be applied twice and marked.

3. Anchor Windlass

- The chain wheel, chain stopper, chain guide roller and hawser should be in a straight line.

- Pay attention to the wear of the teeth of the sprocket and the thread of the worm.

- The wear of the gear teeth of each transmission gear should not exceed 10% of the original thickness.

- Refuel and test drive before each use. Before the steam windlass is used, the water accumulated in the cylinder should be discharged until the steam is sprayed from the drain hole, and then test the drive.

- The clutch is often refueled to ensure light and flexible operation.

4. Anchor Chain Cabin

- Take the opportunity of pouring out all the anchor chains to carry out cleaning work and check whether the drainage equipment is normal.

- Replace the damaged gasket. When necessary, the bilge is re-cemented or repainted.

- Check the wear of the anchor chain pipe.

5. Chain Brake

- The friction surface is often oiled, and the rest should be painted with anti-rust paint.

- Frequently check the fastening of the connection between the base and the deck.

6. Chain Discarder

- Check the integrity of the handwheel protective cover.

- The rotating parts are often refueled.

Choose a Trusted Marine Equipment Supplier

There are many factors to consider when choosing the right anchoring system, including vessel type, vessel size and weight, and docking environment. No matter what conditions your vessel is docked in, Boomarine has the right anchoring system for every vessel!

As a leading designer, manufacturer and supplier of anchors, Boomarine offers all types of anchors, chains and windlasses. As a designer and supplier of high performance and advanced marine anchoring systems, we provide cost-effective end-to-end solutions.