The Structure and Characteristics of a Marine Bollards

A mooring bollard is a mooring device attached to the superstructure of a wharf. Mooring bollards are generally made of metal materials and are named for their columnar shape.

Mooring bollards are designed and selected according to berth capacity and wharf structure type to meet the requirements of safe, reliable and convenient operation of ships leaving the wharf, berthing, shifting and turning around. The bollard is composed of shell, anchor bolt, nut, washer, anchor plate and core packing. Mooring bollards are cast iron, ductile iron and cast steel. Specifications and models: 50KN-2000KN.

The center position of the common mooring bollard is about 0.5-0.8 meters away from the front line, which is too close and easy to be hit by the ship when approaching, and it is not safe for the cable operation. Too far back, hindering the operation of loading and unloading machinery and damaging the cable. For fitting-out and ship repair quay, the bollards are required to be a little farther from the leading edge line (about 0.8-1.0m) due to the facilities such as power boxes at the front.

Storm bollards are used for mooring ships during storms and are generally located behind wharfs. Some ports do not have storm bollards because they are less likely to suffer typhoons, or ships are not sheltered in the harbor during strong winds. In some ports, in order not to interfere with the operation of loading, unloading and transportation machinery, there is no storm bollard at the rear of the wharf, so that the size of the ordinary bollard is enlarged, so that it can also be used in high winds.

Methods for Installing the Embedded Parts of Mooring Bollards

Special embedded parts for mooring bollards of ship port, suitable for fixing all kinds of equipment, steel structure foundation embedded parts, street lamps, traffic signs, pumps, boiler installation, heavy equipment embedded fixed etc. Installation method:

- One time embedding method: when pouring concrete, bury the anchor bolts

- Reserved hole method: the equipment is in place, the hole is cleaned, the anchor bolts are put into the hole, and then the equipment is positioned and aligned, and then the non-shrinkage fine stone concrete which is one level higher than the original foundation is used for watering and tamping. The distance from the center of the anchor bolt to the edge of the foundation shall not be less than 4d(d is the diameter of the anchor bolt), and shall not be less than 150mm (d ≤20 shall not be less than 100mm), and shall not be less than half of the width of the anchor plate plus 50mm. When the appeal requirements cannot be met, appropriate measures shall be taken to strengthen.

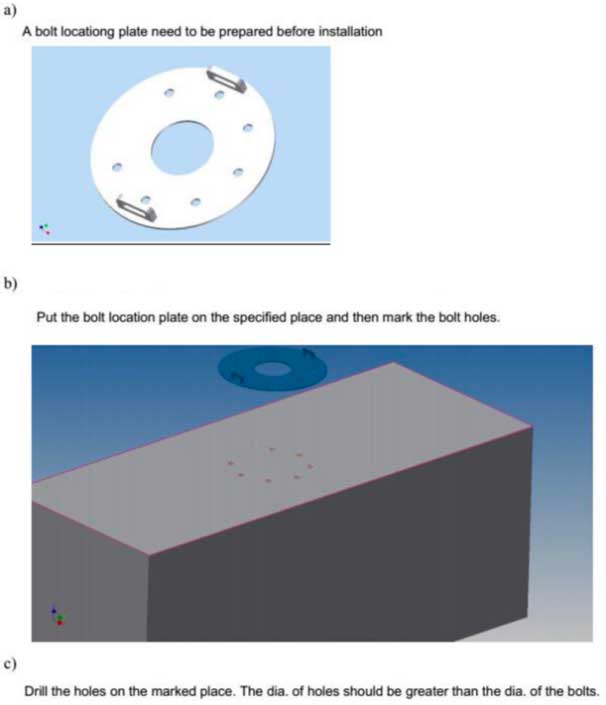

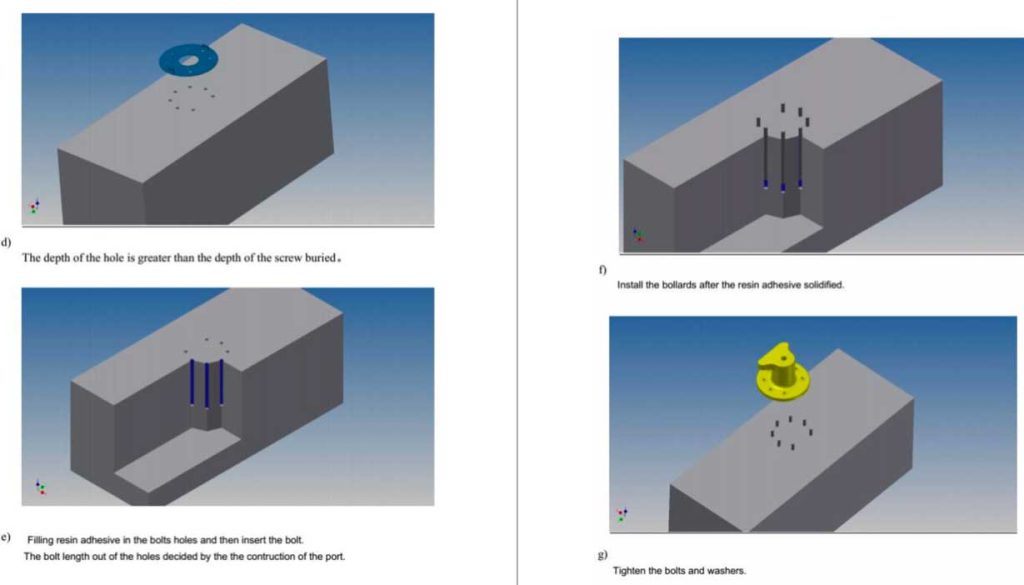

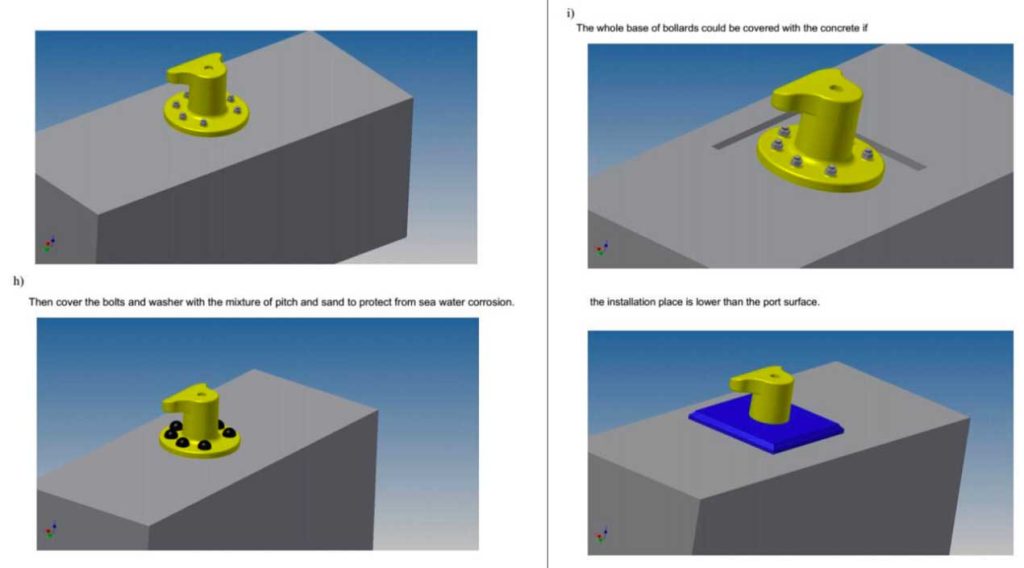

Example of installation steps for existing dock:

- Prepare a location plate.

- Put the plate in the specified place and then mark the bolts holes.

- Drill the holes in the market place.

- The depth of the holes is greater than the depth of the screw buried.

- Fill resin adhesive in the holes, then insert the bolt.

- Install the bollards after the resin adhesive is solidified.