Anchoring system is important equipment in the deck equipment of the ship. To moor a ship in a certain water area, it must drop anchor, and use the anchor’s strength to catch the sediment at the bottom of the water, as well as the weight of the anchor and the chain, to overcome the external forces such as wind and current that make the ship drift. The anchoring system can also assist the maneuvering of the ship, such as turning around in the narrow channel, docking and leaving the dock, and mooring the buoy. After the ship is stranded, the anchor can be used to stabilize the ship’s position, or the anchor can be used to pull the ship out of the shoal.

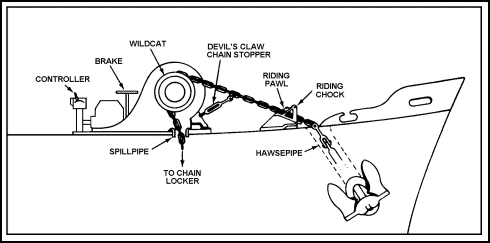

Anchoring system mainly consists of anchor, anchor chain, anchor chain cylinder, chain brake, anchor windlass, anchor chain pipe, anchor chain cabin and chain discarder, etc.

1. Anchor

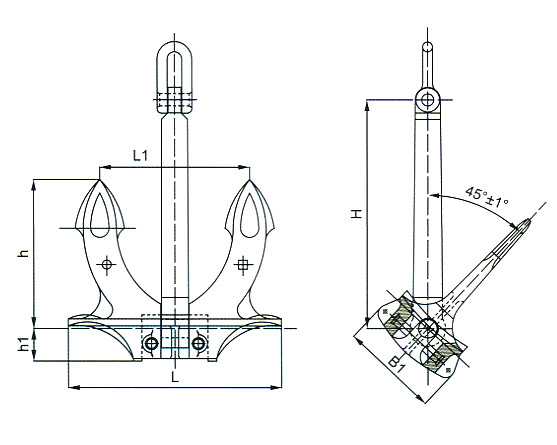

Anchor is a steel structure that can grip into the mud of the seabed. When anchoring, the anchor’s holding force and the undercover anchor chain’s holding force constitute the anchoring force to resist the force of wind and current on the ship. There are many types of anchors, which can be divided into stockless anchors, stocked anchors, high holding power anchors, and special anchors according to their structure and use.

Stocked anchors are also called navy anchors. The anchor stem and the anchor claw are cast as a whole, and the anchor claw will not rotate. It is characterized by simple structure and large grasping-to-weight ratio.

Stockless anchor, also known as mountain anchor and hollow anchor, is a stockless anchor commonly used on merchant ships. The stockless anchor can put the anchor dry into the anchor chain cylinder, so it is suitable for the first anchor, and the holding force is 2~4 times the anchor weight. The mass of the anchor head of the ordinary stockless anchor, including the pin and the shaft, shall not be less than 60% of the total mass of the anchor. The performance is better than stocked anchor, and it has been widely used.

2. Anchor Chain

The anchor chain is a chain connecting the anchor and the hull, which is mainly used to transmit the anchor’s holding force to offset the effect of external force on the ship to ensure that the ship can safely park in the designated waters. The anchor chain is composed of ordinary links, connecting links, connecting shackles, and swivels.

- According to the structure of the anchor chain, it is divided into two types: with gear and without gear. The tensile strength of the geared chain is large, and the anchor ring with the geared chain ring is generally used on the ship.

- According to the manufacturing method, it is divided into cast steel anchor chain, electric welding anchor chain and forged anchor chain. The quality of electric welding anchor chains is higher than other kinds of anchor chains, and the cost is also lower.

- According to the material grade, it is divided into three grades: AM1, AM2 and AM3.

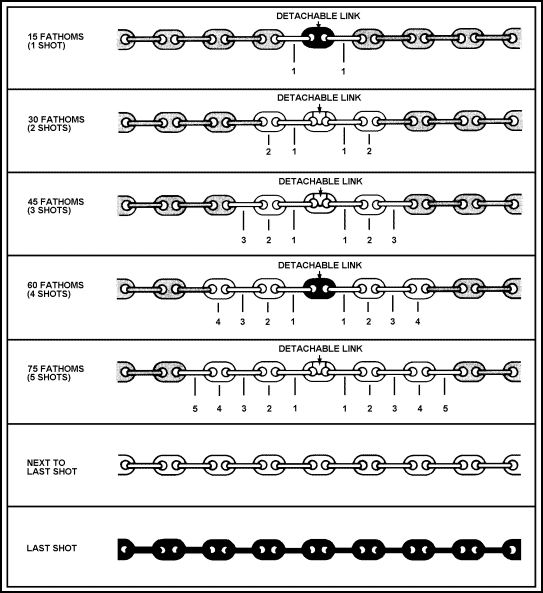

The size of the anchor chain is represented by the diameter d of the ordinary chain link. The diameter of the ordinary chain link is a measure of the strength of the anchor chain. The length of the chain is measured in knots, and the entire anchor chain is connected by several chain links. Chinese regulations stipulate that the length of each standard anchor chain is 27.5m. In some countries with imperial units, 15 fathoms are also used as a chain length, which is equivalent to 27m.

When the anchor is dropped, in order to quickly identify the number of sections of the anchor chain in the water, each section of the anchor chain must be clearly marked. The method is as follows:

- Wires are wound around the first and second rungs of the chain link (or shackle) between the 1st and 2nd sections, and painted with white paint, and the connecting links are painted with red paint, so that the Indicates Section 1.

- Wires are wound around the crosspieces of the second chain link before and after the connecting link (or shackle) between the 2nd and 3rd sections, and painted with white paint, and the connecting link is still painted with red lacquer to indicate Section 2.

- And so on between Sections 5 and 6. Starting from Section 6, repeat the marking in the same way as Section 1, and the last 1 to 2 sections can be marked with red or yellow paint and other eye-catching marks, as the anchor chain will throw all danger warnings.

The chain link at the anchor end is also painted with white paint, as a mark to know that the anchor is about to come out of water and the anchor dry will enter the hawse tube when lifting the anchor, so as to slow down the speed of anchor lifting and avoid damaging the hull or the hawse tube.

An anchor chain sensor is installed on the sprocket on the ship, which can measure the number of anchor chain links and display it on the bridge.

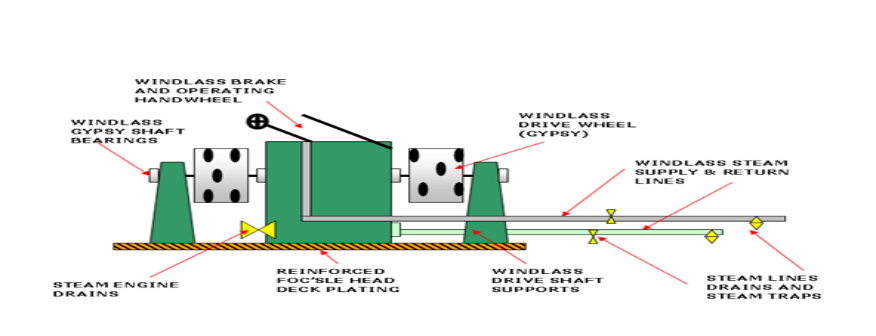

3. Anchor Windlass

Anchor windlass is a mechanical device for dropping, lifting, and twisting cables. The windlass whose sprocket shafts are arranged horizontally is called horizontal windlass, which is generally used by merchant ships. The vertical windlasses are called vertical windlasses, which are mostly used in warships. According to different power, it is divided into four types: electric windlass, hydraulic windlass, steam windlass, and manual windlass. The structure is more or less the same, only when the anchor weight does not exceed 250KG, the ship can be equipped with manual anchor machine.

- Electric windlass is widely used in internal combustion engine ships, and its power source is an electric motor. Through the gear transmission of the reduction box, the pinion drives the large gear to rotate the load shaft. There is a sprocket on the load shaft. The engagement and disengagement of the large gear and the pinion are controlled by the clutch to control the rotation of the sprocket. When the clutch is disengaged, the main shaft and the reel rotate but the sprocket does not rotate, which can be used for anchoring or hoisting. When the clutch is closed, the reel clutch can be disconnected, and only the sprocket can be rotated, which can be used for anchor raising or anchor sending.

- Hydraulic windlass is an electro-hydraulic windlass. Its working principle is similar to that of electric motors. The electric motor drives the hydraulic pump, drives the oil motor, and then passes through the reducer (or not) to make the windlass run. Smooth operation and good shifting performance.

- Steam windlass is rarely used on sea-going ships, and steam windlasses are also used on oil tankers for fire and explosion protection. It is driven by the steam engine, the roller shaft is driven by the gear through the crankshaft, and the sprocket is driven by the rolling shaft through the clutch. Less used, large oil tankers are still used based on explosion-proof requirements.

Features of windlass:

- The windlass can cast and lift the left and right anchors at the same time or separately;

- Able to twist double anchors at the same time from a depth of not less than 45m;

- The clutch can be operated by one person;

- There is a reliable braking device;

- When using the brake strap to break down the anchor, the two anchors can be thrown out separately or simultaneously, and can be braked at any time.

Main technical requirements of windlass:

- Driven by an independent prime mover or electric motor;

- It should be able to pull an anchor from a depth of 82.5 meters underwater to 27.5 meters at an average speed of not less than 9m/min;

- The ability to work continuously for 30 minutes;

- The overload pressure is not less than 1.5 times the working load for 2 minutes;

- Equipped with a clutch and a locking device;

- The sprocket is equipped with a reliable brake;

- The installation of the windlass should generally ensure that the chain drum, the chain maker and the sprocket are in line;

- The windlass operated by remote control shall have a quick-action emergency stop mechanism, and the sprocket shall be equipped with a reliable brake.

After the brake is tightened, the stressed parts should not have permanent deformation and the braking device should not slip under the following loads:

- For the windlass equipped with chain stoppers, it can withstand the chain breaking load of the anchor chain. 45% of the static tension, or when it can withstand the maximum static load on the anchor chain.

- For the windlass device without chain stopper, when it is subjected to static tension of 80% of the breaking load of the anchor chain or wire rope.

The prime mover and transmission should be provided with overload protection to prevent excess torque and impact.

4. Other auxiliary equipment: including chain brake, anchor chain cylinder, anchor chain pipe, anchor chain cabin and chain discarder.

(1) Chain brake is set between the windlass and the anchor chain cylinder, which is used to hold the anchor chain and protect the anchor machine by bearing the external force when anchoring. When sailing, it is used to fasten the anchor and bear the weight of the anchor, and make the anchor chain not bounce and hit the deck.

(2) Anchor chain cylinder is on both sides of the bow, through the deck and shell plate, and consists of three parts: deck chain hole and cylinder, which is the hole head for anchor chain to enter and exit the hull and collect anchor rods. The anchor chain barrel is equipped with water spray holes for washing anchor chain, and water is fed from the deck hose for washing anchor chain when anchoring. In order to prevent seawater from gushing up to the deck from the anchor chain barrel and to ensure the safety of personnel, there is an anti-wake cover at the deck chain hole.

(3) Anchor chain pipe is the pipe for anchor chain to enter and exit the anchor chain compartment. It is installed directly below the left and right sprockets of the anchor machine, facing the center of the anchor chain compartment, and its diameter is 7~8 times of the chain diameter. The anchor chain pipe is equipped with a waterproof cover at the deck mouth, which should be closed after sailing to prevent seawater from entering the anchor chain compartment.

(4) Anchor chain cabin is a compartment for storing anchor chain, which is located before the bow collision bulkhead and below the anchor machine, and its shape is 30 times the diameter of the round anchor chain compartment, so that it is not necessary to discharge the chain manually. The left and right anchor chain compartments are separated, and there are manholes and wall ladders on the middle longitudinal bulkhead for personnel to enter and exit the chain compartment. The bottom of the cabin is padded with wooden boards and steel flower plates in the bottom of the cabin, and there is a drainage pipe system to discharge the water.

(5) Chain discarder is a special device that can make the end anchor chain break away from the ship quickly when the anchor must be abandoned in an emergency.

Erosion Limit of Anchoring System

The average diameter of any chain ring of anchor chain after abrasion shall not be less than 88% or 85% of the original specification diameter. The abrasion limit of the connecting chain ring, anchor unloader, swivel ring and its ring tether shall be the same as above.

The weight loss of anchor should not exceed 20% of the original anchor weight. The base of anchor machine should be replaced or strengthened if the corrosion of the base bolt and nut reaches 25% of the original thickness, and should be replaced if the corrosion of the base bolt and nut is serious.

Major Defects of Anchoring System

Defect 1: The left anchor claw is not facing the right way

Defect 2: The brake belt of the windlass is worn

Defect 3: The anchor chain pipe is corroded and damaged

Defect 4: The ends of the left and right anchor chains are not connected to the hull by the chain dropper as required by the specification