The ISO 13728 Panama Chock Type A is a robust steel fitting designed for safe and efficient mooring line handling on the deck of large ships. Manufactured from high-quality cast steel, it provides a designated pathway for mooring lines, ensuring smooth operation and minimizing wear. Crafted to the exacting standards of ISO 13728, this chock is the pinnacle of reliability, ensuring your cargo stays firmly in place during transit, whether on ships or freight trains.

Designed for heavy-duty performance, the Panama Chock Type A boasts a rugged construction that can withstand the toughest conditions. Its robust build provides unparalleled strength and stability, giving you confidence that your cargo remains secure even in rough seas or turbulent rail journeys.

Choose the ISO 13728 Panama Chock Type A for unmatched cargo security and peace of mind during transit. Whether you’re a shipping company, freight operator, or logistics provider, this chock is your trusted partner for safe and efficient cargo handling. As a leading supplier of marine equipment, Boomarine supplies all kinds of mooring chocks, If you have any needs, please feel free to contact us.

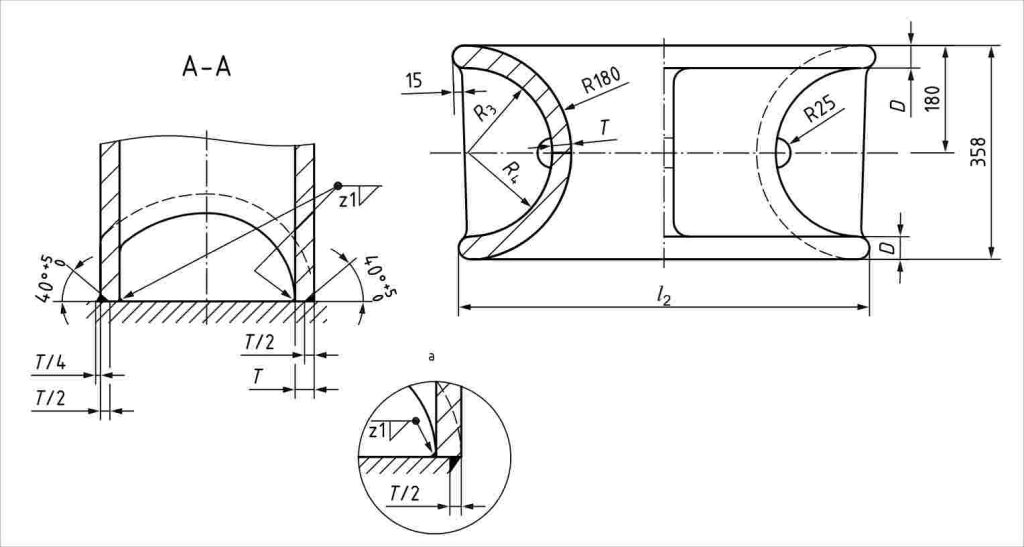

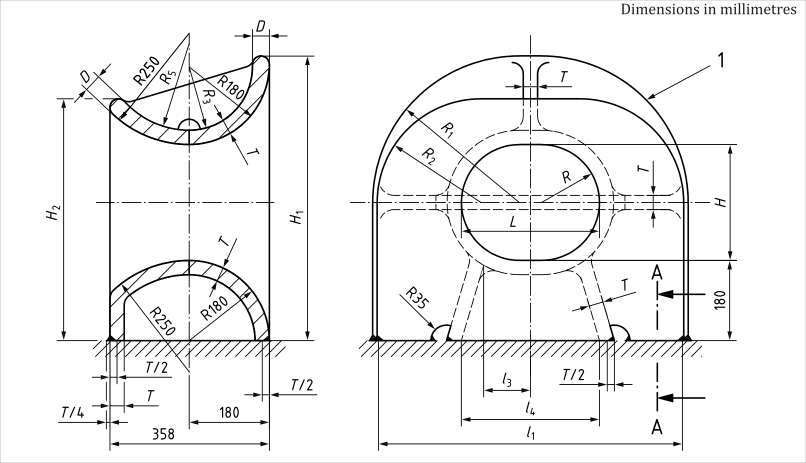

ISO 13728 Panama Chock Type A Dimensions:

| Dimensions of Type A – Deck-mounted Panama Chocks | |||||||||||

| Dimensions in millimetres | |||||||||||

| Nominal size | L | l1 | l2 | l3 | l4 | H | H₁ | H₂ | R | R₁ | R₂ |

| 310 | 310 | 708 | 688 | 105 | 310 | 260 | 639 | 541 | 130 | 329 | 231 |

| 360 | 360 | 760 | 740 | 130 | 360 | 260 | 640 | 543 | 130 | 330 | 233 |

| Dimensions (continued) and SWL of Type A – Deck-mounted Panama Chocks | |||||||||||

| Dimensions in millimeters | |||||||||||

| Nominal size | R₃ | R₄ | R5 | T | D | Welding leg lengtha Z1 | SWLb | Calculated weightc kg | |||

| kN | t | ||||||||||

| 310 | 142 | 140 | 198 | 32 | 38 | 8 | 471 | 48 | 257 | ||

| 360 | 140 | 138 | 196 | 34 | 40 | 85 | 687 | 70 | 286 | ||

| a: The welding method may be changed based on the same welding volume/strength. b: The SWLs shown are for reference only. These are based on the loadings as mentioned in Annex A. The “SWL” which is marked on the fitting may be adjusted depending on the actual loading conditions of the mooring rope under the agreement between the user and the manufacturer. c: The calculated weight (mass)is for reference only. | |||||||||||

ISO 13728 Panama Chock Type A Features:

- Deck-mounted: Different from Type B, It is designed for installation directly onto the ship’s deck, providing easy access for mooring line control.

- Strength and Durability: Constructed from cast steel to withstand the demanding pulling forces exerted by mooring lines on large vessels. Typical safe working loads (SWL) range from 48 to 70 tonnes.

- Standardized Design: Compliant with the ISO 13728 standard, guaranteeing compatibility with mooring equipment used in most major ports and canals around the world.

- Nominal Sizes: Available in diameters of 310mm and 360mm to accommodate various mooring line thicknesses.

ISO 13728 Panama Chock Type A Benefits:

- Enhanced Mooring Line Control: The Panama Chock Type A guides mooring lines, reducing friction and wear during deployment and retrieval.

- Improved Safety: By providing a designated channel for mooring lines, it helps prevent entanglement and potential hazards on deck.

- Operational Efficiency: Streamlines mooring operations by offering a secure and organized mooring line management system.

The ISO 13728 Panama Chock Type A is a vital piece of equipment for any large ship, promoting safe, efficient, and standardized deck mooring practices.

Packing

For different shipping methods and destinations, we will suggest different packaging. If you have any requirements for the packaging, please let me know during the inquiry.

- Wooden Case

- Iron Frame

- Waterproof Carton

- Nude