ISO 13733:2020 Roller Fairlead with Upper Roller

- Standard: ISO 13733:2020

- Material: Cast Steel or Cast Iron

- Roller No.: 4, 5, 7

- Nominal Size: 140mm to 400mm

- Weight: 173kg – 4012kg

- SWL: 137kN to 1373kN

- Surface Treatment: Sandblasting, epoxy primer, polishing, or galvanization are available to meet specific needs.

- Certificate: CCS, NK, ABS, DNV-GL, RINA, etc.

The ISO 13733:2020 Roller Fairlead with Upper Roller is a high-quality marine component designed to ensure smooth and controlled movement of ropes, cables, and mooring lines. This fairlead conforms to the ISO 13733:2020 standard, ensuring dimensional accuracy, material quality, and performance reliability. The inclusion of an upper roller provides additional support and reduces wear on the rope, making it ideal for demanding applications. This fairlead is essential for maintaining proper rope alignment, preventing chafing and damage, and ensuring the safe and efficient operation of lifting and pulling systems.

Depending on the construction, universal fairleads shall be classified as belonging to one of the following four types:

- Type 4R: with one rope-passing opening;

- Type 5RL: with one rope-passing opening with an additional guide roller on the left side;

- Type 5RR: with one rope-passing opening with an additional guide roller on the right side;

- Type 7R: with two rope-passing openings.

Materials of ISO 13733:2020 Roller Fairlead with Upper Roller

The following materials are used for manufacturing the components of universal fairleads.

- Frame and other plates: weldable steel plates having a yield point of not less than 235 N/mm2 except for the frames with a rope guide for nominal sizes 400A, 400B and 400C, which are made of weldable steel plates having a yield point of not less than 315 N/mm2.

- Roller: weldable steel plates having a yield point of not less than 235 N/mm2, except for the rollers for nominal sizes 400A,400B and 400C, which are made of weldable steel plates having a yield point of not less than 315 N/mm2, or equivalent steel tubes.

- Axle: carbon steel having a yield point of not less than 345 N/mm2.

- Bush: brass or bronze or equivalent.

Dimensions of ISO 13733:2020 Roller Fairlead with Upper Roller

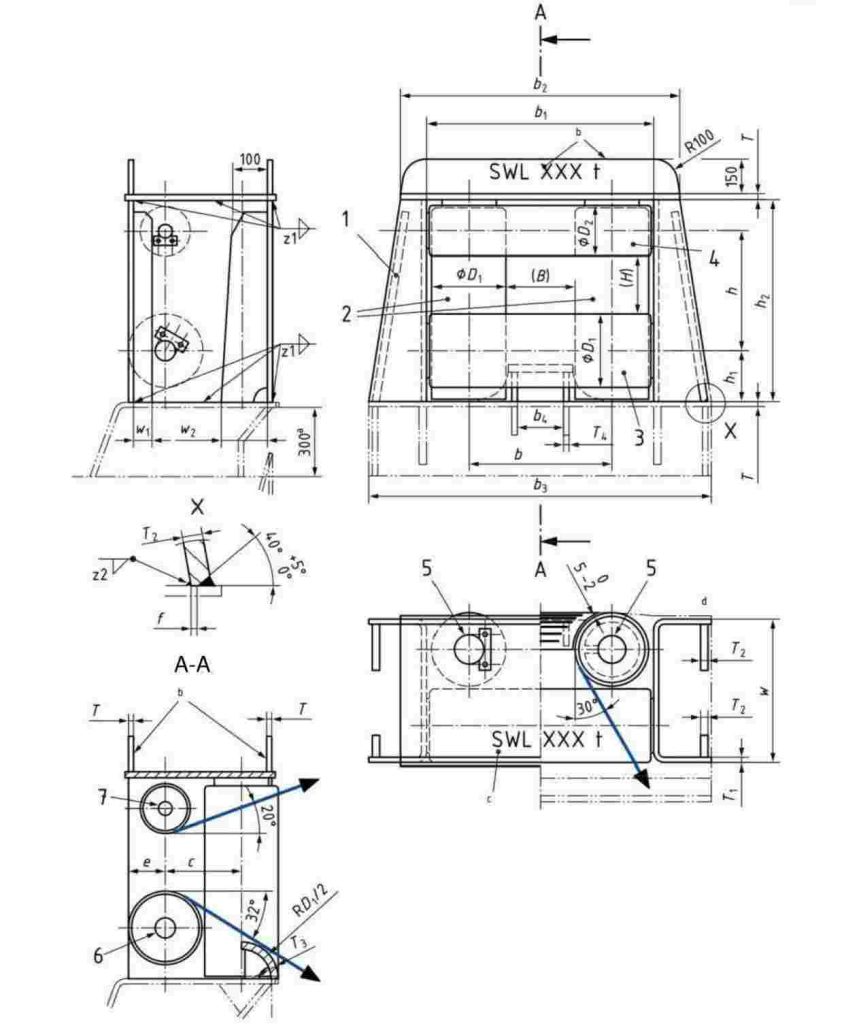

Assembly of 4R universal fairleads

Key Structures

- frame with rope guide

- vertical rollers with housin gand washers

- lower horizontal roller with washer

- supper horizontal roller with washers

- vertical axles with stopper

- lower horizontal axle with stoppers

- upper horizontal axle with stoppers

- type 5RL

- type 5RR

- a. Height of seat shall be determined in accordance with the hull construction design.

- b. For nominal size 250 and above

- c. For nominal size between 140 and 200 only

- d. Side shell

Assembly of 5RL and 5RR universal fairleads

| Table 1—Dimensions of type 4R, 5RL and 5RR universal fairleads | |||||||||||||

| Dimensions in millimeters | |||||||||||||

| Nominal size Dn | B×H | D₁ | D₂ | h | h₁ | h₂ | b | b₁ | b₂ | b₃ | b₄ | W | C |

| 140 | 195×150 | 139,8 | 114,3 | 277 | 130 | 480 | 335 | 515 | 656 | 820 | 140 | 260 | 150 |

| 160 | 200×150 | 165,2 | 114,3 | 290 | 145 | 515 | 365 | 570 | 730 | 920 | 140 | 310 | 175 |

| 180 | 200×150 | 190,7 | 139,8 | 315 | 155 | 560 | 391 | 620 | 800 | 1000 | 140 | 360 | 200 |

| 200 | 200×150 | 216,3 | 139,8 | 328 | 170 | 590 | 416 | 675 | 896 | 1110 | 140 | 410 | 225 |

| 250 | 250×200 | 267,4 | 165,2 | 416 | 195 | 715 | 517 | 825 | 1046 | 1270 | 180 | 520 | 280 |

| 300A | 300×250 | 318,5 | 216,3 | 517 | 220 | 870 | 618 | 980 | 1206 | 1480 | 200 | 620 | 330 |

| 300B | 300×250 | 318,5 | 216,3 | 517 | 220 | 870 | 618 | 980 | 1206 | 1480 | 200 | 620 | 330 |

| 400A | 350×250 | 406,4 | 216,3 | 561 | 265 | 960 | 756 | 1210 | 1450 | 1750 | 200 | 795 | 420 |

| 400B | 350×250 | 406,4 | 216,3 | 561 | 265 | 960 | 756 | 1210 | 1450 | 1750 | 200 | 795 | 420 |

| 400C | 350×250 | 406,4 | 216,3 | 561 | 265 | 960 | 756 | 1210 | 1450 | 1750 | 200 | 795 | 420 |

| Table2—Dimensions(continued) and SWL of type 4R, 5RL and 5RR universal fairleads | |||||||||||||||

| Dimensions in millimeters | |||||||||||||||

| Nominal size Dn | e | W₁ | W₂ | T | T₁ | T₂ | T₃ | T₄ | f | We leng Z₁ | ing leg tha, b Z2 | SWLC | Dimensions in millimeters | ||

| kN | t | 4R | 5R | ||||||||||||

| 140 | 70 | 30 | 100 | 12 | 10 | 10 | 12 | 12 | 3 | 7 | 4 | 137 | 14 | 173 | 213 |

| 160 | 83 | 40 | 100 | 14 | 10 | 14 | 14 | 14 | 4 | 7 | 5 | 196 | 20 | 246 | 305 |

| 180 | 95 | 40 | 100 | 16 | 10 | 14 | 16 | 16 | 4 | 7 | 5 | 245 | 25 | 313 | 392 |

| 200 | 108 | 50 | 100 | 18 | 12 | 16 | 18 | 18 | 6 | 9 | 7 | 314 | 32 | 430 | 532 |

| 250 | 133 | 65 | 200 | 22 | 16 | 18 | 20 | 20 | 6 | 11 | 7 | 510 | 52 | 841 | 1031 |

| 300A | 159 | 80 | 200 | 24 | 20 | 22 | 24 | 22 | 7 | 14 | 8 | 687 | 70 | 1364 | 1666 |

| 300B | 159 | 80 | 200 | 26 | 22 | 24 | 24 | 22 | 8 | 15 | 9 | 736 | 75 | 1463 | 1786 |

| 400A | 203 | 100 | 200 | 26 | 22 | 22 | 32 | 28 | 7 | 15 | 8 | 981 | 100 | 1971 | 2387 |

| 400B | 203 | 100 | 200 | 28 | 24 | 26 | 32 | 28 | 8 | 17 | 9 | 1256 | 128 | 2240 | 2731 |

| 400C | 203 | 100 | 200 | 30 | 26 | 28 | 32 | 28 | 8 | 18 | 9 | 1373 | 140 | 2395 | 2922 |

| a. Welding with chamfering is available based on the same welding volume/strength. b. Welding otherwise than mentioned in the Figures in this document and this table: minimum leg length shall be 1/2 of thinner plate thickness. c. The SWLs shown in this table are for reference only. These are based on the loadings as mentioned in Annex A. The“SWL” which is marked on the fitting may be adjusted depending on the actual loading conditions of the mooring rope under the agreement between the user and the manufacturer. d. The calculated weight (mass)is for reference only excluding foundation. | |||||||||||||||

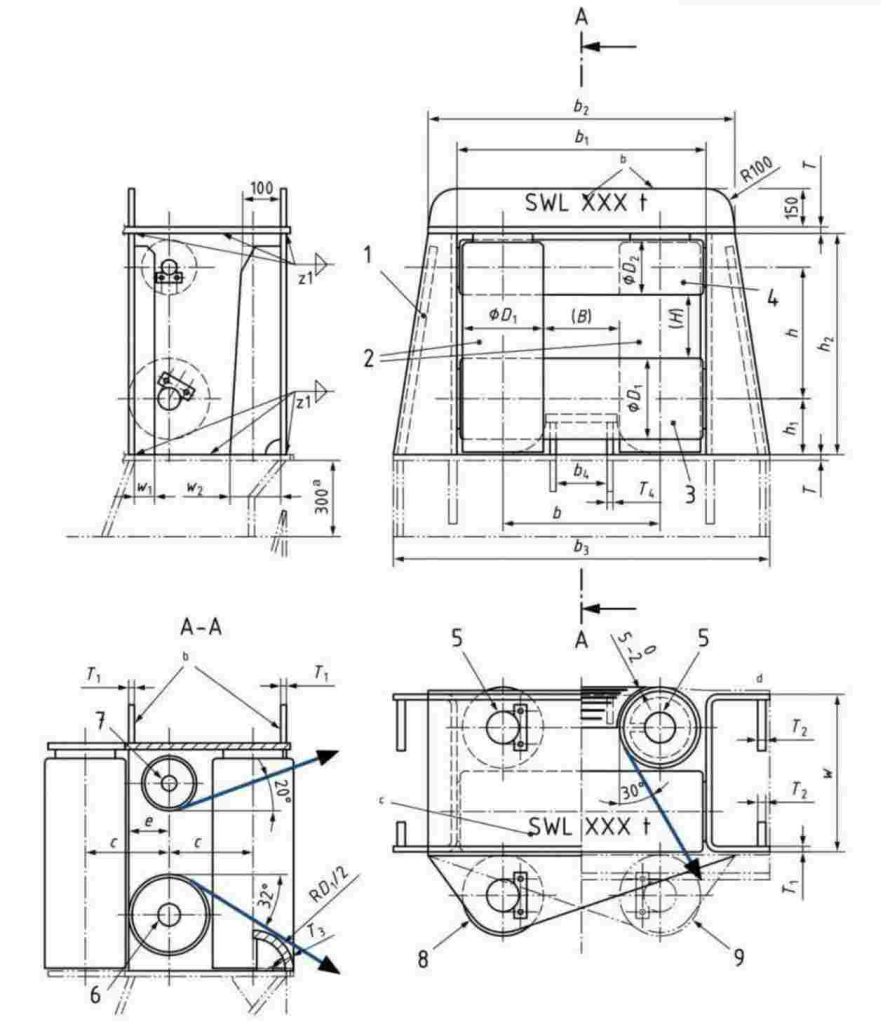

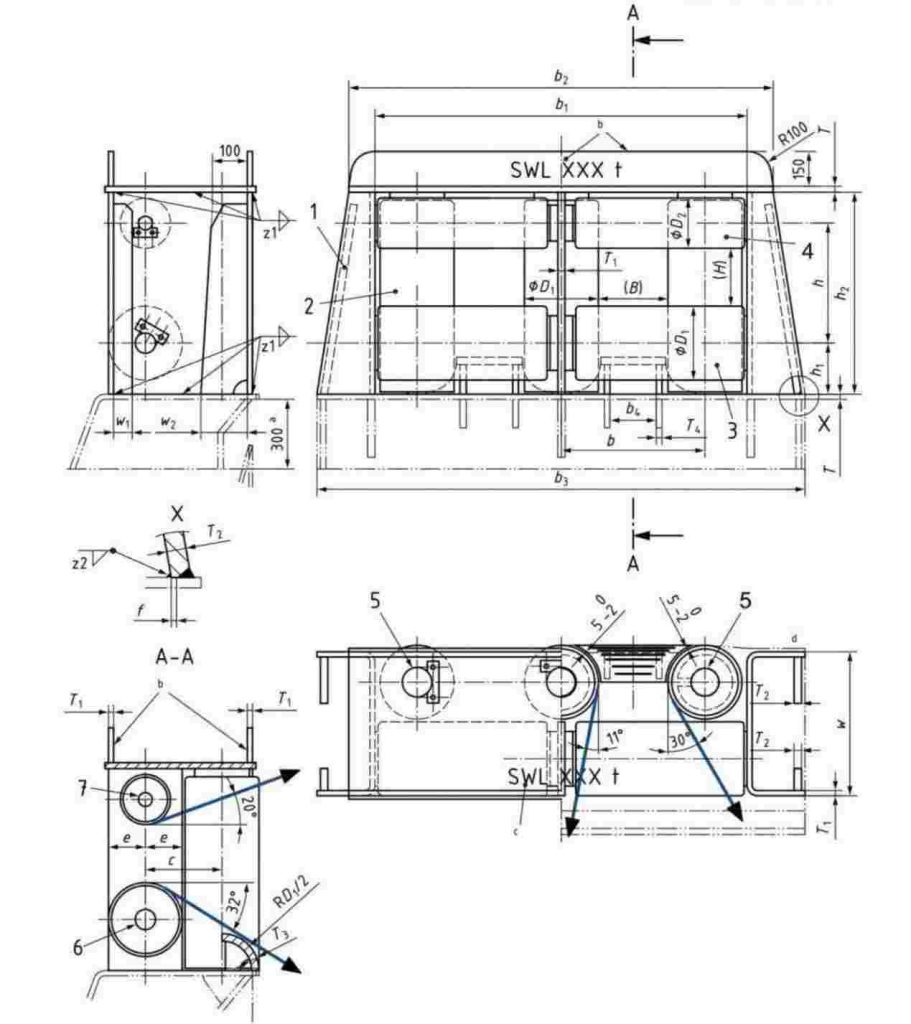

Assembly of 7R universal fairleads

Key Structures

- frame with rope guide

- vertical rollers with housing and washers

- lower horizontal roller with housing and washers

- upper horizontal roller with housing and washers

- vertical axles with stopper

- lower horizontal axle with stoppers

- upper horizontal axle with stoppers

- a. Height of seat shall be determined in accordance with the hull construction design.

- b. For nominal size 250 and above

- c. For nominal size between 140 and 200 only

- d. Side shell

| Table 3—Dimensions of type 7R universal fairleads | |||||||||||||

| Dimensions in millimeters | |||||||||||||

| Nominal size Dn | B×H | D₁ | D₂ | h | h₁ | h₂ | b | b₁ | b₂ | b₃ | b₄ | W | C |

| 140 | 195×150 | 1398 | 114.3 | 277 | 130 | 480 | 335 | 850 | 1000 | 1160 | 140 | 260 | 150 |

| 160 | 200×150 | 1652 | 1143 | 290 | 145 | 515 | 365 | 935 | 1100 | 1286 | 140 | 310 | 175 |

| 180 | 200×150 | 1907 | 1398 | 315 | 155 | 560 | 391 | 1011 | 1200 | 1400 | 140 | 360 | 200 |

| 200 | 200×150 | 2163 | 1398 | 328 | 170 | 590 | 416 | 1091 | 1320 | 1550 | 140 | 410 | 225 |

| 250 | 250×200 | 2674 | 1652 | 416 | 195 | 715 | 517 | 1342 | 1580 | 1820 | 180 | 520 | 280 |

| 300A | 300×250 | 3185 | 2163 | 517 | 220 | 870 | 618 | 1598 | 1840 | 2150 | 200 | 620 | 330 |

| 300B | 300×250 | 3185 | 2163 | 517 | 220 | 870 | 618 | 1598 | 1840 | 2150 | 200 | 620 | 330 |

| 400A | 350×250 | 4064 | 2163 | 561 | 265 | 960 | 756 | 1966 | 2250 | 2550 | 200 | 795 | 420 |

| 400B | 350×250 | 4064 | 2163 | 561 | 265 | 960 | 756 | 1966 | 2250 | 2550 | 200 | 795 | 420 |

| 400C | 350×250 | 4064 | 2163 | 561 | 265 | 960 | 756 | 1966 | 2250 | 2550 | 200 | 795 | 420 |

| Table 4—Dimensions(continued) and SWL of type 7R universal fairleads | ||||||||||||||

| Dimensions in millimeters | ||||||||||||||

| Nominal size Dn | e | W₁ | W₂ | T | T₁ | T₂ | T₃ | T₄ | f | Weld leng Z₁ | ing leg tha, b Z2 | SWLC | Calculated weightd | |

| kN | t | kg | ||||||||||||

| 140 | 70 | 30 | 100 | 12 | 12 | 18 | 12 | 12 | 6 | 9 | 7 | 137 | 14 | 276 |

| 160 | 83 | 40 | 100 | 14 | 14 | 20 | 14 | 14 | 6 | 10 | 7 | 196 | 20 | 398 |

| 180 | 95 | 40 | 100 | 16 | 16 | 28 | 16 | 16 | 8 | 11 | 9 | 245 | 25 | 547 |

| 200 | 108 | 50 | 100 | 18 | 18 | 28 | 18 | 18 | 8 | 13 | 9 | 314 | 32 | 713 |

| 250 | 133 | 65 | 200 | 22 | 26 | 36 | 20 | 20 | 10 | 18 | 10 | 510 | 52 | 1473 |

| 300A | 159 | 80 | 200 | 24 | 28 | 46 | 24 | 22 | 10 | 20 | 10 | 687 | 70 | 2301 |

| 300B | 159 | 80 | 200 | 26 | 30 | 48 | 24 | 22 | 10 | 21 | 10 | 736 | 75 | 2449 |

| 400A | 203 | 100 | 200 | 26 | 30 | 40 | 32 | 28 | 10 | 21 | 10 | 981 | 100 | 3317 |

| 400B | 203 | 100 | 200 | 28 | 32 | 52 | 32 | 28 | 10 | 22 | 10 | 1256 | 128 | 3767 |

| 400C | 203 | 100 | 200 | 30 | 34 | 54 | 32 | 28 | 10 | 24 | 10 | 1373 | 140 | 4012 |

| a. Welding with chamfering is available based on the same welding volume/strength. b. Welding otherwise than mentioned in the Figures in this document and this table: minimum leg length shall be 1/2 of the thinner plate thickness. c. The SWLs shown in this table are for reference only. These are based on the loadings as mentioned in Annex A. The“SWL” which is marked on the fitting may be adjusted depending on the actual loading conditions of mooring rope under the agreement between the user and the manufacturer. d. The calculated weight (mass)is for reference excluding foundation. | ||||||||||||||

Features of ISO 13733:2020 Roller Fairlead with Upper Roller

- Compliant with ISO 13733:2020 Standards: Meets the latest global standards for marine fairleads, ensuring top-notch performance and safety.

- Dual Roller Design (with Upper Roller): The upper roller provides additional support and minimizes rope contact, reducing friction and wear, extending rope life, and improving overall system efficiency. This is especially beneficial for applications with high loads or frequent rope movement.

- High-Strength Materials: Constructed from corrosion-resistant and high-strength materials, ensuring long-lasting performance even in harsh marine environments.

- Durable & Low Maintenance: Built to withstand heavy-duty applications with minimal maintenance requirements, saving time and costs for operators.

- Versatile Mounting Options: Designed for easy installation and compatibility with various marine equipment, including winches, capstans, and mooring systems.

- Improved Rope Life: The roller system ensures reduced wear on ropes and cables, contributing to their extended lifespan.

Applications of ISO 13733:2020 Roller Fairlead with Upper Roller

- Marine Industry: Ideal for use in vessels, offshore platforms, and shipping operations, particularly for mooring lines, towing cables, and anchor handling.

- Offshore Oil & Gas Operations: Ensures smooth handling of cables and lines in challenging offshore environments.

- Commercial Shipping & Freight: Assists in secure rope management for loading, unloading, and towing operations.

- Harbor & Port Facilities: Enhances the safety and efficiency of mooring and docking procedures.

Why Choose Our ISO 13733:2020 Roller Fairlead with Upper Roller?

- Increased Rope Lifespan: Reduces wear and tear on ropes, saving money on replacements.

- Improved Safety: Ensures proper rope handling, minimizing the risk of accidents.

- Enhanced Efficiency: Facilitates smooth and efficient operation of lifting and pulling systems.

- Reduced Downtime: Durable construction and reliable performance minimize maintenance requirements.

- Compliance with Standards: Meets ISO 13733:2020 standards, ensuring quality and interchangeability.