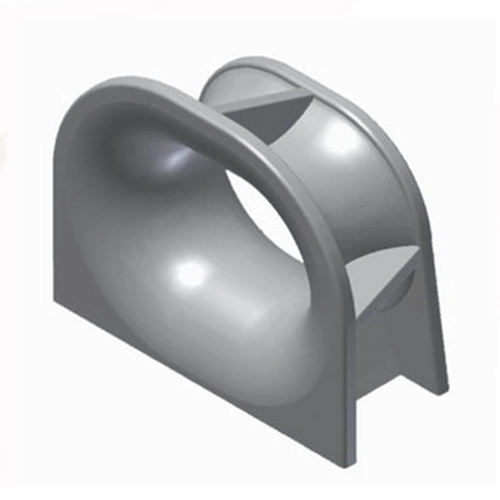

DIN 81915 Bulwark Mounted Panama Chock is designed and manufactured as per DIN81915 standards, which is a popular type of mooring chock. It is made of cast steel GS-38 (material 1.0420) equal to ZG230-450, the seat and bulwark are made by processing steel sheet. It is usually installed on both sides of the tanker for general mooring purposes. And it is directly welded into the bulwark.

The surface of this type of mooring chock requires smoothness, especially in contact with the ropes. And it needs sandblasting and primer for surface treatment.

DIN 81915 Bulwark Mounted Panama Chock is widely used for vessels, tugs, cargo ships, military ships, industrial ships, etc.

Except for bulwark mounted Panama chocks, we also have deck mounted Panama chocks. As a leading supplier of marine equipment in China, Boomarine provides all types of high quality mooring chocks. Each product will be strictly tested and inspected by ourselves or a third-party company before delivery, and for all products, we will provide at least an 18-month quality warranty.

Features of DIN 81915 Panama Chock Type A:

- Guide the rope from the inboard to the outboard at certain direction, change the trend of rope and limit its place.

- Made of cast steel GS-38 (material 1.0420 ) equal to ZG230-450.

- Its surface is smooth to contact with the ropes.

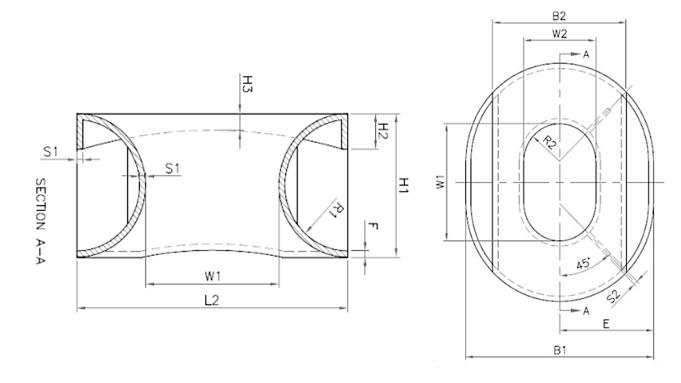

Dimensions: (mm)

|

Type |

Dimension(mm) |

|||||||

|

|

B1 |

B2 |

H1 |

H2 |

H3 |

L2 |

R1 |

R2 |

|

A2 |

315 |

225 |

200 |

70 |

25 |

360 |

100 |

57.5 |

|

A3 |

390 |

275 |

250 |

75 |

32 |

450 |

125 |

70 |

|

A5 |

480 |

340 |

300 |

80 |

38 |

550 |

150 |

90 |

|

A8 |

585 |

415 |

360 |

90 |

45 |

680 |

180 |

112 |

|

A12 |

710 |

500 |

440 |

110 |

55 |

840 |

220 |

135 |

|

A20 |

840 |

595 |

520 |

130 |

65 |

1020 |

260 |

160 |

|

A32 |

1100 |

800 |

700 |

150 |

80 |

1300 |

350 |

200 |

|

Type |

S1 |

S2 |

W1 |

W2 |

Weight |

Working Load(KN) |

||

|

A2 |

12 |

6 |

160 |

115 |

26 |

20 |

||

|

A3 |

14 |

7 |

200 |

140 |

42 |

30 |

||

|

A5 |

16 |

8 |

250 |

180 |

74 |

50 |

||

|

A8 |

18 |

9 |

320 |

225 |

120 |

80 |

||

|

A12 |

20 |

10 |

400 |

270 |

185 |

120 |

||

|

A20 |

22 |

11 |

500 |

320 |

285 |

200 |

||

|

A32 |

35 |

20 |

600 |

400 |

795 |

320 |

||

Why Choose Us?

- Strong design and production capacity.

- Strict inspection, including incoming inspection, flaw detection, etc., must be double-checked.

- Advanced factory equipment.

- Provide professional and final customized services according to customer requirements.

- Delivery on time, because we have a strict production plan and professional follow-up process.

- Competitive price, professional after-sales service.

- Response to any inquiry within 24 hours with design or efficient solution from our engineer or tech supporter.