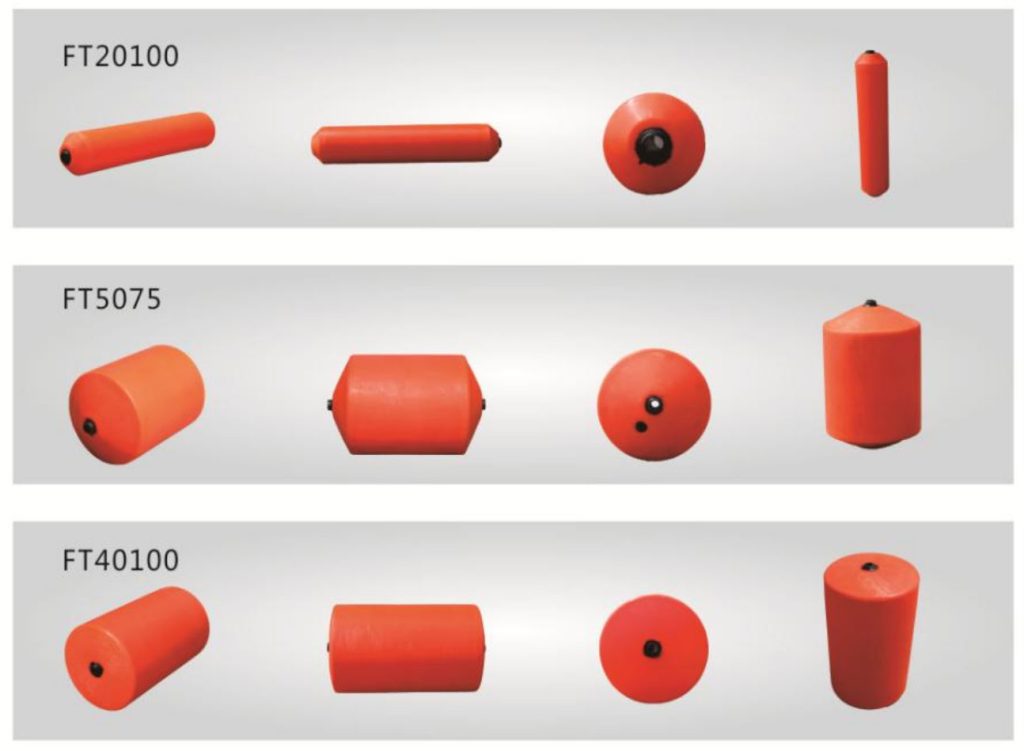

Cylindrical Buoy is designed for float control, safe area marking, aquaculture projects and other marine applications. These cylindrical buoys typically consist of an enclosed EPS foam core wrapped in a tough, corrosion-resistant HDPE shell (high density polyethylene). Its inner diameter is 40mm standard, but can also be customized if required.

EPS foam ensures that the buoy does not absorb moisture from skin pricks, extending product life and reducing maintenance costs. The elastic material makes the buoy self-defense with high shock absorption. And the natural color HDPE elastomer skin is resistant to abrasion and UV degradation.

As a professional marine equipment supplier, Boomarine offers various types of marine buoys. And according to customer’s requirements, we can provide a wide range of sizes, and can print LOGO on the buoy.

Features of Cylindrical Buoy:

- High Environmental Protection: Made of environmentally friendly food-grade HDPE material.

- Abrasion Resistant Construction: Features a durable double skin and internal plenum.

- Corrosion Resistance: The shell of the buoy is made of HDPE material, which is resistant to acid, alkali and seawater corrosion.

- Light Weight: In case of typhoons, the buoy will not be skewed.

- Shock-absorbing technology prevents damage to buoys or boats.

- Closed-cell foam core filling prevents loss of buoyancy when punctured.

- Steel core central strength member with load distribution structure.

Specifications:

| Model | Inner Diameter (mm) | Outside Diameter (mm) | Length (mm) | Thickness (mm) | Buoyancy (kg) |

| FT150*500 | 40 | 150 | 500 | 3 | 6 |

| FT150*550 | 40 | 150 | 550 | 3 | 7 |

| FT200*1000 | 40 | 200 | 1000 | 4 | 28 |

| FT220*1000 | 40 | 220 | 1000 | 4 | 32 |

| FT220*1550 | Wear the screw | 220 | 1550 | 5 | 50 |

| FT250*500 | The suspension loop | 250 | 500 | 4 | 23 |

| FT250*850 | 40 | 250 | 850 | 5 | 35 |

| FT300*500 | 40 | 300 | 500 | 4 | 30 |

| FT300*800 | 40 | 300 | 800 | 5 | 50 |

| FT300*1000 | 40 | 300 | 1000 | 4 | 65 |

| FT380*480 | 40 | 380 | 480 | 4 | 50 |

| FT380*580 | 40 | 380 | 580 | 4 | 60 |

| FT400*800 | 40 | 400 | 800 | 5 | 70 |

| FT400*1000 | 40 | 400 | 1000 | 6 | 110 |

| FT500*750 | 40 | 500 | 750 | 5 | 90 |

| FT500*800 | 40 | 500 | 800 | 6 | 130 |

| FT500*900 | \ | 500 | 900 | 6 | 140 |

| FT550*950 | 40 | 550 | 950 | 6 | 210 |

| FT600*760 | 40 | 600 | 760 | 5 | 180 |

| FT600*1000 | 40 | 600 | 1000 | 6 | 220 |

| FT600*1100 | \ | 600 | 1100 | 6 | 290 |

| FT800*900 | \ | 800 | 900 | 7 | 420 |

| FT800*1200 | \ | 800 | 1200 | 8 | 550 |

| FT1000*1000 | 40 | 1000 | 1000 | 8 | 650 |

| FT1000*1200 | 40 | 1000 | 1200 | 8 | 850 |

Application Cases:

Cylindrical buoy can be used as floating barrier (barrier floats) and warning floating line:

The design of the floating barrier depends on what is to be contained, i.e. garbage, oil slicks, and also on-site conditions, i.e. high-speed rivers, deep reservoirs, etc. Typically, floating barriers consist of buoys, cables, nets, ballast, or positioning buoys. With increasing environmental awareness, floating barriers are rapidly gaining popularity around the world.

The integrated floating body is the main barrier to intercept the floating garbage on the water, and the connection method is series.

- Warning Floating Line can be simply used to guide, direct or demarcate non-entry areas to prevent the accidental entry of individuals or ships, etc.

- In order to achieve a better warning effect, the warning floating line often inserts marker buoys with warning lights or adds luminous bands to the main buoys, which makes the warning floating Line boundary clearer and provides a clearer view.

- The design and model selection of the warning floating line is determined by the functions to be achieved, the water regime of the target waters, the geographical status, etc. The location of the Warning Floating Line can be achieved either by the fixed pile on the shore or in the water, or by the use of the anchor buoy. The main body is usually composed of a cylindrical buoy or afloat, connected by a main rope cable.

Why Choose Our Cylindrical Buoys?

- 100% Raw Materials Imported From Korea

After years of testing and demonstration of raw material solution flow rate, resin density and resin thermal stability, we have selected 100% raw materials suitable for plastic buoys.

- Advanced Rotational Moulding Process

Rotational molding is a manufacturing process used to create seamless, stress-free hollow products. Additional crafts can be added, such as filling with EPS foam.

- Beautiful Appearance, High Performance

The buoy consists of an impact-resistant rotationally molded polyethylene casing. The filling material of the buoy is expanded polystyrene foam (EPS). The buoyancy capabilities of our products have been developed and tested over many years.

- Customized Service

If our standard products do not meet your requirements, we are more than happy to design and manufacture products that meet your unique requirements.