JIS F2001 Double Bitt Bollard is a type of mooring equipment installed on ships to mooring and towing ropes. It is based on Japanese Industrial Standards, and is mainly designed and manufactured according to berthing capacity and wharf structure to meet the safety and convenience of wharf, mooring, shifting and turning around.

JIS F2001 Double Bitt Bollard is mainly made by welding steel plates and steel pipes. Its appearance has no cracks, no defects or rust that are not conducive to use, and has a good smoothness. The nominal diameter ranges from 100mm to 800mm, and the weight ranges from 18.9KG to 3071KG. Its’ appearance ropes are wire rope, manila and sisal fiber rope, synthetic rope, and so on.

The bollard can withstand use in harsh environments. Due to its dual horn shape, it can accept multiple mooring ropes. Because it is subjected to a lot of force during use, its base is required to be very firm. In order to prevent the rope from slipping off the pile, the top of the pile is usually covered with a pile cap slightly larger than the pile body. On ships, this bollard is usually installed on the bow, stern, and left and right decks of the middle.

Boomarine is a professional marine equipment supplier. In addition to JIS F2001 Double Bitt Bollard, we can also provide you with other standard marine bollards. And it is recognized by different classification societies, such as CCS, ABS, BV, DNV, LR, NK and other IACS members. For more information, please feel free to contact us.

Features of JIS F2001 Double Bitt Bollard:

- High strength, not easy to deform.

- Good craftsmanship, beautiful and practical.

- The surface of the bollard is oxidized, which is not easy to be corroded.

- The surface is without any visible flaws or imperfections.

- Long service life, up to 15-20 years.

Modern ships, especially large ships such as container ships, oil tankers, bulk carriers, etc., can load and unload more than 10,000 tons of cargo within a few hours. As a result, the draught of the ship changes rapidly. Therefore, there are automatic mooring machinery and bollards, which can automatically retract and unwind the cables according to the changes in the cable tension to ensure the safety of the ship and the wharf.

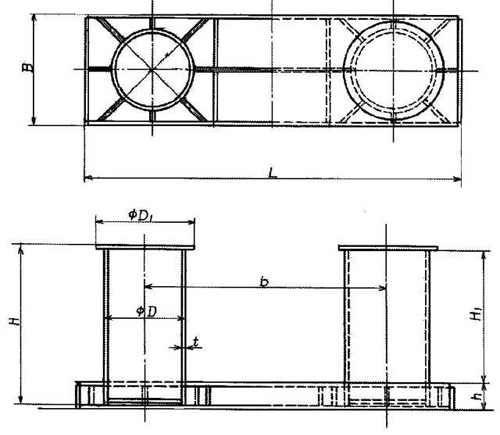

Dimensions: (mm)

| Nominal Size | Dimensions (mm) | SWL | Weight | ||||||||

| Dn (mm) | D | D1 | H | H1 | t | b | B | h | L | (kN) | (kg) |

| 100 | 114.3 | 145 | 196 | 150 | 10 | 250 | 165 | 50 | 445 | 29 | 18.9 |

| 125 | 139.8 | 180 | 246 | 190 | 10 | 315 | 195 | 60 | 540 | 39 | 29.4 |

| 160 | 165.2 | 210 | 316 | 250 | 10 | 400 | 225 | 70 | 670 | 49 | 44.7 |

| 200 | 216.3 | 270 | 378 | 300 | 10 | 500 | 290 | 85 | 860 | 78 | 79.5 |

| 250 | 267.4 | 330 | 470 | 380 | 11 | 630 | 360 | 100 | 1065 | 118 | 139 |

| 315 | 318.5 | 385 | 597 | 480 | 15 | 800 | 430 | 125 | 1300 | 196 | 261 |

| 355 | 355.6 | 425 | 663 | 530 | 17 | 890 | 480 | 145 | 1475 | 255 | 361 |

| 400 | 406.4 | 485 | 749 | 600 | 18 | 1000 | 550 | 160 | 1630 | 314 | 502 |

| 450 | 457.2 | 550 | 841 | 680 | 19 | 1130 | 620 | 170 | 1840 | 382 | 685 |

| 500 | 508 | 610 | 928 | 750 | 20 | 1250 | 690 | 190 | 2040 | 451 | 911 |