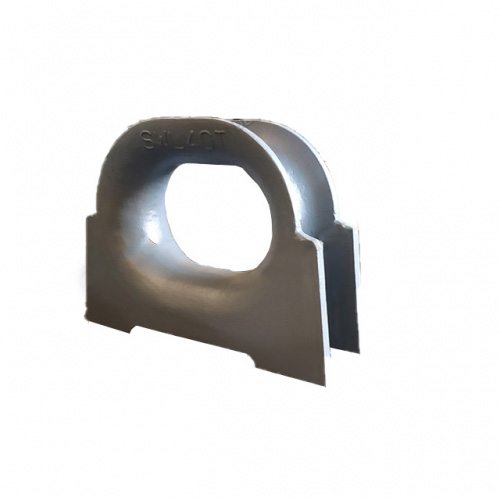

DIN 81915 Panama Chock Type B is built in accordance with DIN 81915 standards, our Panama Chock Type B is engineered to ensure secure and efficient mooring operations on vessels of various sizes. Its robust construction, made of cast steel GS-38 (material 1.0420) equal to ZG230-450, guarantees longevity even in the harshest marine environments.

This Type B Panama Chock has a smooth surface, is coated with an anti-corrosion protective coating on the outside, and the enclosed housing protects the lines from UV rays and abrasion. Carefully crafted to meet the stringent requirements of the shipping industry, this mooring chock is a testament to quality and durability.

While DIN81915 Panama chocks are a solid option, Boomarine is your one-stop shop for a wider range of mooring chocks. We cater to the specific mooring needs of any vessel. All Boomarine mooring chocks can be supplied with ABS, BV, LR, CCS, and other classification society certificates. This guarantees they meet the strictest industry regulations, ensuring your peace of mind.

Features of DIN 81915 Panama Chock Type B:

- DIN 81915 Compliance: This chock strictly adheres to DIN 81915 standards, ensuring that it meets the stringent requirements for safety and performance in maritime applications.

- Premium Materials: Crafted from corrosion-resistant materials, the Panama Chock Type B withstands the challenges of saltwater exposure, ensuring a prolonged lifespan and minimal maintenance requirements.

- Optimized Design: The chock’s design is optimized for ease of use and versatility. It provides a reliable point of attachment for mooring lines, contributing to the overall efficiency and safety of mooring operations.

- Easy Installation: Featuring a user-friendly design, the Panama Chock Type B facilitates straightforward installation, minimizing downtime and streamlining the maintenance process.

- Corrosion Resistance: The chock’s materials are chosen for their resistance to corrosion, rust, and other environmental factors, ensuring reliability in even the most challenging marine conditions.

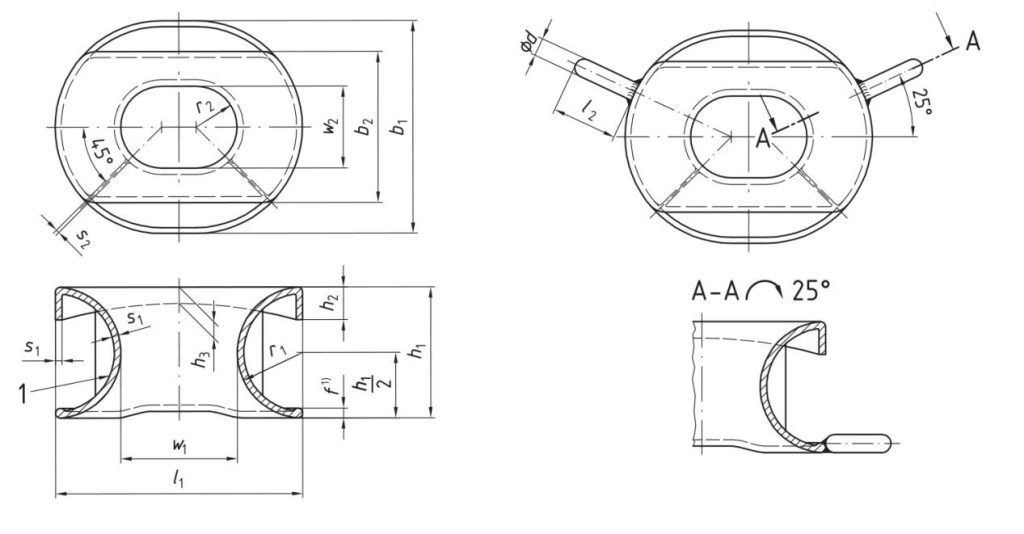

Dimensions: (mm)

| Type | Wire W.L (KN) | b1 | b2 | h1 | h2 | h3 | L1 | r1 | r2 | S1 | S2 | w1 | w2 | d | L2 |

| B3 | 30 | 390 | 275 | 250 | 75 | 32 | 450 | 125 | 70 | 14 | 7 | 200 | 140 | 40 | 140 |

| B5 | 50 | 480 | 340 | 300 | 80 | 38 | 550 | 150 | 90 | 16 | 8 | 250 | 180 | 45 | 160 |

| B8 | 80 | 585 | 415 | 360 | 90 | 45 | 680 | 180 | 112.5 | 18 | 9 | 320 | 225 | 50 | 180 |

Applications DIN 81915 Panama Chock Type B::

- Merchant ships

- Workboats

- Tugboats

- Any vessel requiring secure mooring at docks or harbors

DIN 81915 Panama Chock: Type B vs. Type D

- Choose Type B: For high-tension mooring scenarios where maximum line security and protection are crucial.

- Choose Type D: For applications requiring a chock suitable for both mooring and short-distance towing, or when easier line handling is preferred.

For both types:

- Manufactured from cast steel for superior strength and durability.

- Compliant with the DIN 81915 quality standard.

- Specific details on size, weight, and working load limits depend on the manufacturer. Consult a marine equipment supplier for further information and to determine the most appropriate type for your needs.

Why Choose Boomarine Mooring Chocks?

- Vast Selection: We offer a diverse range of mooring chocks to suit any application.

- Unwavering Quality: Our chocks are built to meet the highest industry standards.

- Certification Flexibility: Obtain the classification society certificate required for your project.

- Expert Guidance: Benefit from our team’s knowledge to select the ideal mooring solution.

Don’t limit yourself. Contact Boomarine today and secure your vessel with the perfect mooring chocks!