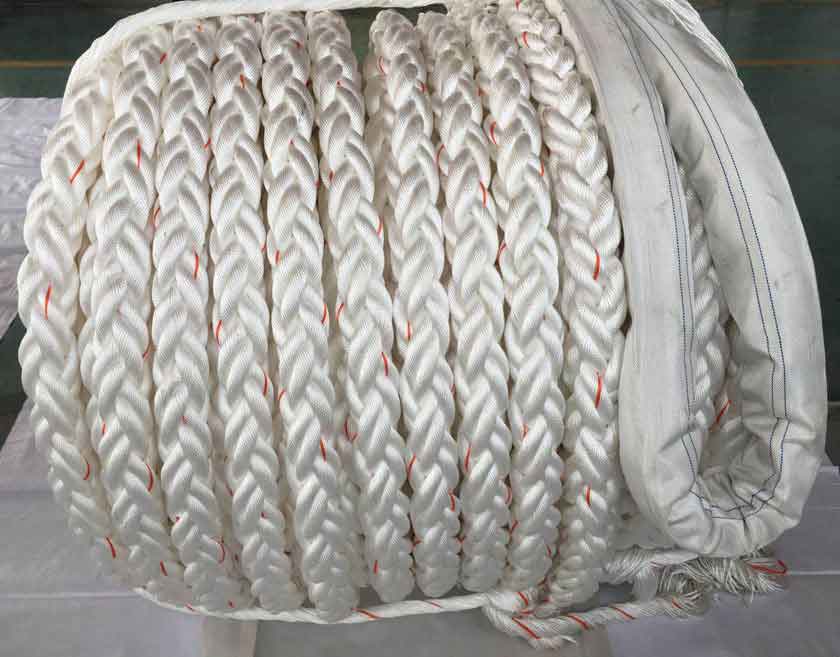

Ultra High Molecular Weight Polyethylene (UHMWPE) rope, also known as Dyneema Rope, is produced with ultra-high molecular weight polyethylene fiber and high technology, it’s high strength, lightweight, and low elongation. Because it is woven, not twisted, it will not rotate when loaded. It is rolled into a small coil and will not be kinked like a wire rope.

UHMWPE rope is a safer alternative than steel wire rope. It is 7-9 times stronger than steel (by weight) and 3 times stronger than polyester of the same weight. It’s small size (due to the small size used), so even by one person, it can be easily stored and quickly deployed in an emergency.

UHMWPE rope can float in the water to make it safer. Its low stretch characteristics provide higher sensitivity. And its low elongation combined with its low weight makes it easy to operate and the ship’s handling is extremely accurate, especially in distress and critical moments.

With its high strength-to-weight ratio, smooth handling and low tensile properties, UHMWPE rope is the first choice for ship auxiliary ropes, offshore drilling platforms and oil tankers. As a professional mooring rope supplier, Boomarine provides high-quality UHMWPE ropes. Our UHMWPE rope exceeds the ISO 10325 standard and the price is competitive. If you have any needs, please feel free to contact us!

Features of UHMWPE Rope

- Stronger: For the same dia., the strength is the same as the wire rope.

- Lower Elongation: The breaking elongation is close to the wire rope.

- Lighter: In the same strength, the weight is only 1/8 of the wire rope, 1/4-1/5 of the nylon rope or polyester rope, and 18%-20% of the polypropylene rope.

- Smaller: In the same strength, the dia. of the UHMW PE rope is 55%-60% of the nylon rope or polyester rope, and 45% of the polypropylene rope.

- Excellent wear resistance: The wear life of UHMWPE rope is 4 times that of steel wire rope and rope made of ordinary HMPE and polyester.

- Good chemical resistance: Due to its molecular structure, UHMWPE can withstand most chemicals, including detergents, mineral acids and oils. However, it can be corroded by strong oxidants.

Applications of UHMWPE Rope

- Towing heavy objects, especially boats

- Traction, winch, traction line

- Cranes and pulley systems that need to lift heavy objects

- Specialty Rigging Line

- Anchor rope

- Replace the wire rope

Specification of UHMWPE Rope

| SPECIFICATION 8-STRAND & 12-STRAND | |||||||||||

| Size | Weight | Type I | Type I | Type II &III | Type II &III | ||||||

|

Breaking Strength ISO MBF |

Breaking Strength MEG4 LDBF |

Breaking Strength ISO MBF |

Breaking Strength MEG4 LDBF |

||||||||

| mm Dia. | Inch Cir. | g/m | kg/220m | KN | Ton | KN | Ton | KN | Ton | KN | Ton |

| 36 | 4-1/2 | 720 | 158.4 | 1104 | 112.7 | 994 | 101.4 | 840 | 85.7 | 756 | 77.1 |

| 40 | 5 | 880 | 193.6 | 1329 | 135.6 | 1196 | 122.0 | 1027 | 104.8 | 924 | 94.3 |

| 42 | 5-1/4 | 979 | 215.4 | 1459 | 148.9 | 1313 | 134.0 | 1142 | 116.5 | 1028 | 104.9 |

| 44 | 5-1/2 | 1078 | 237.2 | 1589 | 162.1 | 1430 | 145.9 | 1258 | 128.3 | 1132 | 115.5 |

| 46 | 5-3/4 | 1171 | 257.6 | 1698 | 173.2 | 1528 | 155.9 | 1366 | 139.4 | 1230 | 125.5 |

| 48 | 6 | 1264 | 278.1 | 1807 | 184.4 | 1626 | 181.0 | 1475 | 150.5 | 1327 | 135.4 |

| 50 | 6-1/4 | 1388 | 305.4 | 1971 | 201.1 | 1774 | 196.1 | 1619 | 165.2 | 1457 | 148.7 |

| 52 | 6-1/2 | 1512 | 332.6 | 2136 | 217.9 | 1922 | 211.2 | 1764 | 180.0 | 1588 | 162.0 |

| 54 | 6-3/4 | 1636 | 359.9 | 2300 | 234.7 | 2070 | 226.3 | 1909 | 194.8 | 1718 | 175.3 |

| 56 | 7 | 1760 | 387.2 | 2464 | 251.5 | 2218 | 240.8 | 2053 | 209.5 | 1848 | 188.6 |

* MBF: Mini Breaking Force according to ISO2307.

* LDBF: Line Design Break Force according to OCIMF MEG4 appendix B

* Other sizes are available upon request

What is UHMWPE?

UHMWPE (Ultra High Molecular Weight Polyethylene), also known as HMPE (High Modulus Polyethylene) or HPPE (High Performance Polyethylene), is a polyolefin resin with extremely high molecular weight (quality), usually in the range of 2 to 6 million Between g/mol, there are extremely long chains produced by gel spinning (wet or dry). Longer chains more effectively transfer loads to the polymer backbone by enhancing intermolecular interactions. This results in a very tough material with the highest impact strength of any thermoplastic currently manufactured.

UHMWPE is odorless, tasteless and non-toxic. In addition to oxidizing acids, it has strong resistance to corrosive chemicals, has very low hygroscopicity (hydrophobicity), very low friction coefficient, self-lubricating and high wear resistance, in some forms, resistance the abrasiveness is 15 times that of carbon steel. Its friction coefficient is significantly lower than nylon and acetal, comparable to polytetrafluoroethylene (PTFE, Teflon), but UHMWPE has better wear resistance than PTFE. UHMWPE material floats in water, so it has another advantage over many other materials such as polyester, nylon, aramid, LCP, etc.

UHMWPE materials can be classified as special engineering plastics. It is an indispensable product on the world market, with unparalleled wear resistance, surface lubricity and impact strength, combined with the excellent chemical properties of HDPE. It mainly competes with polyacetal, nylon, polytetrafluoroethylene and polyaramid in fiber form, but it also has many unique markets.