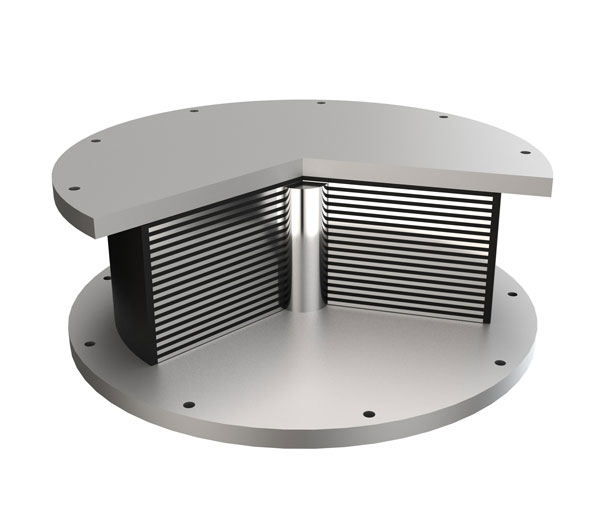

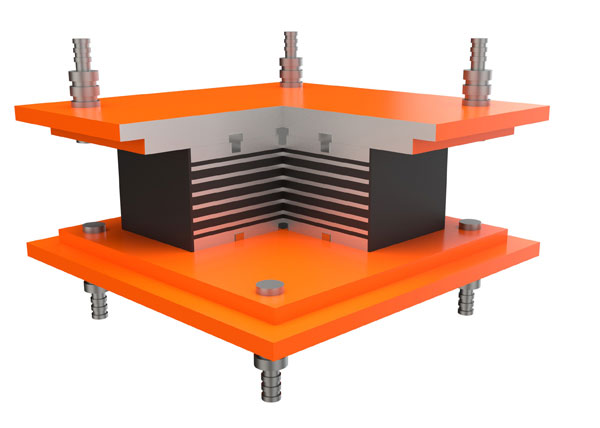

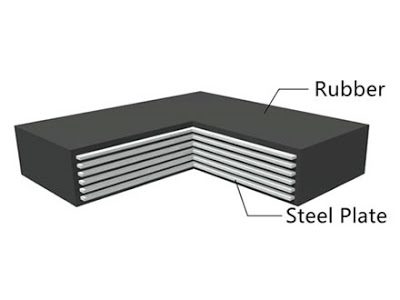

Laminated Rubber Bearing is composed of a multilayer stiffening plate, and steel plate all wrapped in the rubber elastic material inside and outside. The bearing has enough vertical stiffness to withstand the bridge’s internal force, and can be reliably transmitted to the pier; good elasticity and shear deformation ability by rubber materials, in order to meet the angle and displacement of the upper structure. The damping property of rubber material can reduce the impact of dynamic load on the superstructure and pier, and play the role of buffer and isolation.

Compared with other types of bridge bearings, laminated rubber bearings are easier to install in the bridge without maintenance. It is a practical and economical seismic isolation option. Unlike most other elastomers, when the thermal shrinkage of the bridge deck is greatest, neoprene will not harden significantly at low temperatures.

Laminated rubber bearings can be used in steel structures, precast concrete structures, standard concrete slabs, and anywhere vibration isolation is required. This type of bearing is particularly effective in the presence of camber and rotation which causes high stress loads on the bearing. This type of bearing provides an excellent economical solution for applications where structural movement, longitudinal, lateral and rotation are minimal. And it provides vibration isolation and is often easy to install.

Boomarine is a professional supplier of bridge bearings. The laminated rubber bearings we provide are specially designed for bridge and building construction. At the same time, they are designed and manufactured in accordance with international standards such as EN 1337, AASHTO, BS 5400, AS 5100 or DIN 4141. They can also be customized according to customer requirements to meet different usage scenarios.

Specifications of Laminated Rubber Bearing

| Standard | JT/T4-2004 | BS5400 Section 9.2 | |||

| Rubber | Natural Rubber |

Neoprene CR |

Natural Rubber |

Neoprene CR |

|

| Hardness(IRHD) | 60±5 | 60±5 | 50±5/60±5/70±5 | ||

| Tensile Strength (M Pa)≥ | 18 | 17 | 17 | 15.5 | |

| Ultimate Elongation (%)≥ | 450 | 400 | 450/400/350 | 400/350/300 | |

| Compression Set | 70℃ × 22h | 70℃ × 22h | 100℃ × 22h | ||

| <30 | <15 | <30 | <35 | ||

| Heat Resistance | Test Condition | 70℃ × 168h | 100℃ × 70h | 70℃ × 168h | 100℃ × 48h |

| Change in Hardness | -5,+10 | 0,+10 | <10 | <15 | |

| (IRHD) | |||||

| Rate of Tensile Strength Reduction(%) | <15 | <15 | |||

| Rate of Ultimate | <20 | <40 | <20 | <40 | |

| Elongation Reduction | |||||

| (%) | |||||

| Ozone Resistance | 25~50pphm,20% strain | 25~50pphm,20% strain | |||

| 40℃ × 96h | 30℃ × 96h | ||||

| No Cracks | No Cracks | ||||

Features of Laminated Rubber Bearing

- Strong in the vertical direction, but flexible in the horizontal direction.

- High durability and maintenance-free.

- Excellent vertical load capacity, ranging from 5 tons to 2000 tons.

- Easy to install without a separate damper.

- Simple structure, easy manufacturing, low cost, saving steel.

- The rubber has good elasticity and damping properties, and the rubber bearing has good shock absorption performance, which can reduce the dynamic load of the bridge span structure and the impact of the pile body, thereby improving the stress of the bridge.

Applications of Laminated Rubber Bearing

It has a wide range of applications and can adapt to wider bridges, curved bridges and slanted bridges, but it is usually used for short-span cast concrete slabs in bridges or precast concrete slabs used in multi-story stadiums.

Different plane shapes are suitable for different span structures: orthogonal bridges are suitable for rectangular bearings; curved bridges, skew bridges and cylindrical pier bridges are suitable for circular bearings.

Although elastic bearings are designed to accommodate shear motion, they should not be used to provide permanent resistance to continuously applied external shear forces.

Working Principle of Laminated Rubber Bearing

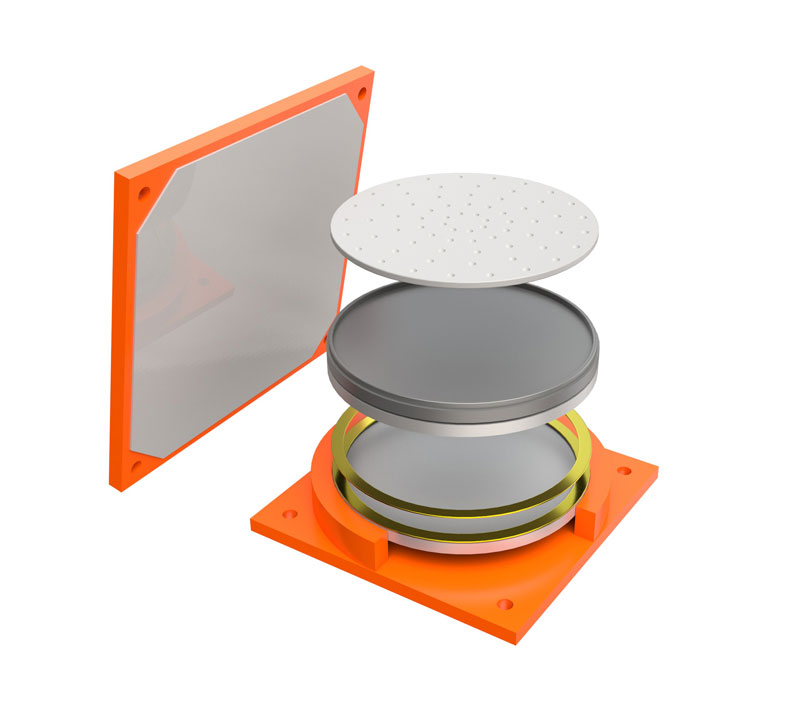

In an earthquake, unisolated buildings vibrate back and forth in different directions due to inertial forces, resulting in building deformation and damage. In contrast, a foundation-isolated building will also shift but maintain its original shape and avoid damage – this is because the lead rubber bearing effectively dissipates the inertial forces on the building, extending the building’s vibration period and reducing the building’s acceleration.

The lead plug slides with the laminated rubber during earthquakes, but converts this motion energy into heat, which effectively reduces the inertial forces on the building, thereby slowing down the building’s vibration. At the same time, the rubber part will retain its original shape due to its high elasticity.

Ruber Physical & Mechanical Properties

| Physical Properties | ||||

| Physical Properties | CR | NR | EPDM | |

| Hardness | 60±5 | 60±5 | 60±5 | |

| Tensile Strength/Mpa ≥ | 17 | 18 | 15 | |

| Elongation at Break/% ≥ | 400 | 450 | 350 | |

| brittleness temperature(ºC) ≤ | -40 | -50 | -60 | |

| EN Compression Set(70ºC*24h)/% ≤ | 15 | 30 | 25 | |

| Ozon Resistance(20% elongation, 40ºC*96h) | 100*10-3 | 25*10-8 | 100*10-8 | |

|

Air Oven Aging(Max change, comparing with datas without aging) |

Test Conditions(ºC*h) | No Crack | No Crack | No Crack |

| Tensile Strength(%) ≤ | 100*70 | 70*168 | 100*70 | |

| Elongation at Break/% ≤ | 15 | 15 | 15 | |

| Hardness Change | 40 | 20 | 40 | |

| Peel Strength between Rubber and Steel(kN/m) ≥ | 0~+10 | -5~+10 | 0~+10 | |

| Peel Strength between Rubber and PTFE(kN/m) ≥ | 10 | 10 |

10 |

|

| Mechnical Properties | ||

| Ultimate Compressive Strength Ru(MPa) | ≥70 | |

| Measure of Compressive Elastic Mould E1(MPa) | E±E*30% | |

| Measure of Shear Elastic Mould G1 (MPa) | G±G*15% | |

| Measure of Shear Elastic Mould after Aging G2 (MPa) | G1±G1*15% | |

| Measure Corner Tangent tgθ | Concrete Bridge | ≥1/300 |

| Steel Bridge | ≥1/500 | |

| Measure Friction Coefficient μf (with grease) | ≤0.03 | |

Classification of Laminated Rubber Bearing

Classification as shapes:

- Rectangular laminated rubber bearing

- Circular laminated rubber bearing

Classification as the applicable temperature of adhesive varieties:

- Neoprene bearing (applicable temperature -25~60°C)

- NR bearing (applicable temperature -35~60°C)

- EPDM bearing (applicable temperature -40~60°C)

Rectangular Laminated Bearing is available as below: