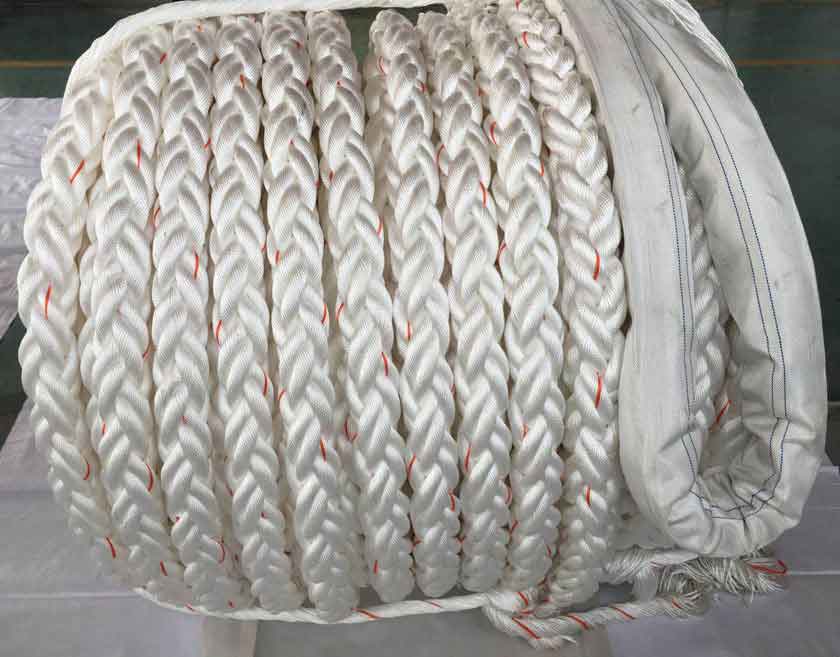

Nylon Ropes absorb water and are with high strength, a great elongation rate, and good abrasion resistance. Compared with other chemical fiber ropes, it’s with best shock absorption, longer service life, and better resistance to UV and other corrosion.

Nylon braided rope is the most widely used of all ropes in use. Nylon rope is stretched with a “memory” of returning to its original length. For this reason, it is the best rope to absorb the shock load. Nylon can last 4-5 times longer than natural fibers.

As a professional manufacturer and supplier of nylon ropes, Boomarine provides the highest quality and selected nylon ropes. Besides, we can provide all types of mooring ropes for sale. We have more than 10 years of industry experience and are experts in marine mooring ropes. Contact us now to learn more!

Features of Nylon Ropes

- Nylon is the strongest among the most common rope fibers, obviously stronger than polypropylene, polyethylene or organic fibers, and barely beats polyester.

- Nylon rope has a high stretch coefficient and can stretch up to 40% (more commonly 15-25%).

- Nylon rope is very suitable for shock absorption and dynamic load applications due to its elasticity, making it a clear choice for mooring and towing activities and certain anchoring applications.

- Nylon rope is resistant to decay and mildew, but can be particularly dyed in water-soluble stains.

- The nylon material of the rope has good UV resistance.

- It feels soft and comfortable, can be dyed, and has a variety of colors to choose from.

- The price is cheap and very cost-effective.

* One of the only weaknesses of nylon rope is that it absorbs water and therefore becomes weak when wet or immersed in water.

Applications of Nylon Ropes

Nylon rope is probably one of the most widely used ropes, which is usually used in pulley systems or winches, because of its wear resistance and shock absorption. The shock-absorbing properties of nylon ropes make them very suitable for lifting or towing operations where the rope needs to absorb dynamic loads. It is usually used in ship mooring, navy ships, pelagic fishing, and sea farming.

Specification for 8 strands & 12 strands nylon ropes

|

Size |

Weight |

Type I |

Type I |

Type II |

Type II |

||||||

|

|

|

Breaking Strength ISO MBF |

Breaking Strength MEG4 LDBF |

Breaking Strength ISO MBF |

Breaking Strength MEG4 LDBF |

||||||

|

mm Dia. |

Inch Cir. |

g/m |

kgs/220m |

KN |

Ton |

KN |

Ton |

KN |

Ton |

KN |

Ton |

|

24 |

3 |

355 |

78.1 |

127 |

12.9 |

114 |

11.6 |

|

|

|

|

|

28 |

3-1/2 |

485 |

106.7 |

184 |

18.8 |

166 |

16.9 |

|

|

|

|

|

32 |

4 |

630 |

138.6 |

235 |

23.9 |

11 |

21.5 |

|

|

|

|

|

36 |

4-1/2 |

830 |

182.6 |

296 |

30.2 |

266 |

27.2 |

|

|

|

|

|

40 |

5 |

1000 |

220.0 |

350 |

35.7 |

315 |

32.1 |

463 |

47.3 |

417 |

42.6 |

|

44 |

5-1/2 |

1210 |

266.2 |

417 |

42.5 |

375 |

38.3 |

560 |

57.2 |

504 |

51.4 |

|

45 |

5-5/8 |

1248 |

274.6 |

437 |

44.6 |

393 |

40.1 |

584 |

59.6 |

526 |

53.6 |

|

48 |

6 |

1430 |

314.6 |

501 |

51.1 |

450 |

46.0 |

656 |

66.9 |

590 |

60.2 |

|

50 |

6-1/4 |

1535 |

337.7 |

537 |

54.8 |

484 |

49.3 |

16 |

73.1 |

645 |

65.8 |

|

52 |

6-1/2 |

1680 |

369.6 |

588 |

60.0 |

529 |

54.0 |

777 |

9.3 |

700 |

71.4 |

* MBF: Mini Breaking Force according to ISO2307.

* LDBF: Line Design Break Force according to OCIMF MEG4 Appendix B.

* Other sizes are available upon request.

What do we need to pay attention to in the process of use and maintenance of nylon ropes?

Although nylon braided rope is good, it should be used to a degree. The degree referred to here is the application field of nylon braided rope. Users can not apply the product to various fields because of the toughness and high hardness of nylon braided rope.

Nylon braids can produce toxic substances, such as dimethane, after being boiled at high temperatures. The toxin will seep into the boiling water, so don’t use a nylon cord to wrap food that needs heating.

Maintenance in the process of use:

- Can not burst in the sun (afraid of heat), acid corrosion (alkali), put in the car trunk pull to pull, etc. (the above behavior in addition to acid and alkali corrosion is not absolute).

- Rope cleaning: can be washed with water (neutral or special washing liquid) after spreading on the ground to dry;

- Avoid damage by hard objects during use;

- Although trampling does not cause damage to the rope, it should be avoided.

The Development of Nylon Ropes:

Early nylon ropes, while superior to those made of natural fibers, were stiff and caused a lot of friction, making them extremely difficult to use because they were too elastic. The nylon rope was gradually replaced by the woven nylon rope. Modern woven nylon ropes are divided into core lines and sheaths. The middle core line is a parallel or braided nylon wire that provides most of the tension resistance and cushioning. The outer layer is covered with a smooth nylon sheath, which mainly protects the core of the rope. Woven nylon rope retains the characteristics of nylon rope, to remove the shortcomings of nylon rope – rough, too much friction, too good elasticity.