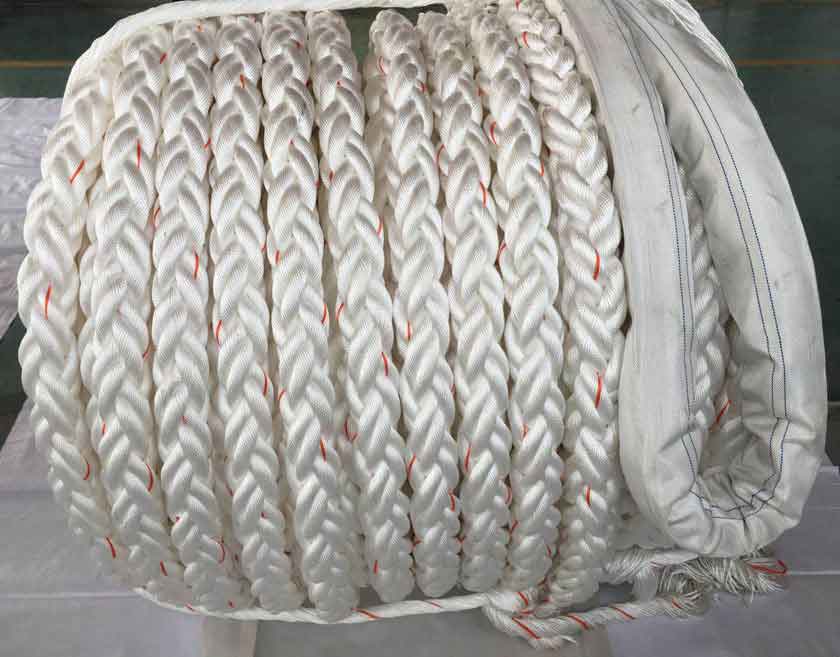

Polyamide double braid rope – the single-point mooring line (also known as SPM) is a circular, double-woven structure, an innovative design that offers higher strength, better wear resistance and longer service life than traditional ropes. The SPM line is made up of a 12-strand core with a protective cover. This design keeps high strength and good abrasion resistance performance, it is the first choice for single-point mooring.

Both ends with galvanized cast thimble and polyurethane protection, it would raise the abrasion resistance performance of rope. The rope itself around the ring needs to be coated with a polyester fiber braided covering sheath (the thickness of the sheath is no less than 6 mm), and then coated with polyurethane glue on the outer layer of the rope to increase the wear resistance of the cable. The cable shall be loaded with floats 25 feet from the ring. The number of floats must meet the specified requirements.

With more than 10 years of sales, engineering and manufacturing experience in marine equipment, Boomarine is fully capable of providing you with the high-quality mooring ropes and quality services you need, to help you make profitable and wise purchasing decisions.

Features of Polyamide Rope

- Made of 100% polyamide raw materials and has excellent wear resistance.

- Excellent shock absorption and torque balance structure.

- Good strength-to-weight ratio.

- Has good flexibility, no creases when bent.

- When dry, polyamide is a good electrical insulator.

- The melting point is 215°C, which is highly adaptable to the environment, but please stay away from open flames.

Applications of Polyamide Rope

The abrasion resistance of polyamide rope makes it ideal for pulley systems or winches. The shock absorption properties of polyamide rope make it very suitable for lifting or towing operations where the rope needs to absorb dynamic loads.

The most common uses: traction ropes, anchor ropes, pulleys, winches, tie-down devices, fall protection systems.

Specification of Polyamide Rope – 8 & 12 Strands

| Diameter | Circum. | Weight | Breaking Strength(Ton) | |

| mm | Inch | kg/100m | Single | Grommet |

| 80 | 10 | 398 | 148 | 252 |

| 88 | 11 | 482 | 179 | 304 |

| 96 | 12 | 572 | 208 | 354 |

| 104 | 13 | 672 | 250 | 425 |

| 112 | 14 | 772 | 288 | 490 |

| 120 | 15 | 887 | 327 | 556 |

| 128 | 16 | 1010 | 368 | 626 |

| 136 | 17 | 1140 | 419 | 712 |

| 144 | 18 | 1280 | 460 | 782 |

| 152 | 19 | 1420 | 501 | 852 |

| 160 | 20 | 1580 | 551 | 937 |

| 168 | 21 | 1740 | 599 | 1018 |

* Other sizes are available upon request

Precautions when using polyamide rope

- It is sensitive to high temperatures and degrades to release toxic substances, including cyanide.

- Good resistance to oil and organic solvents, formaldehyde and alcohol.

- Poor tolerance (not recommended for use) phenols, alkalis, iodine and acids, and chlorine should also be avoided.

- Polyamide can resist insects, fungi, animals, mold, mildew and rot.

- Because it absorbs water, it gets dirty easily.

Why Choose Us?

- Rich rope production, sales experience, and passed ISO 9001 and international classification certification.

- Especially designed ropes and solutions can be provided according to the application environment and characteristics.

- Multiple production lines and imported equipment can efficiently produce all kinds of ropes, and the delivery time and rope quality are guaranteed.

- Every process from fiber to finished rope is strictly checked.

- With more than 10 years of export history, the rope can be delivered to the designated place on time.