PP rope – Polypropylene multifilament rope is easy to handle, feels soft and smooth, and absorbs water, known as “floating nylon”. PP rope is widely used as a mooring line, it has the same strength either under wet conditions or normal conditions. It is easy operation, has chemical corrosion resistance, drains well, and keeps it in a dark place.

PP rope strength is the same in wet and dry conditions, and it can float so it’s often used in marine and fishery.

The disadvantage of PP rope is weak in UV resistance. To slow the degradation of polypropylene rope, anti-oxidants and ultraviolet inhibitors may be added to last the rope serving life.

When transporting important goods and materials, the use of suitable and reliable load-limiting mooring ropes is essential. If you use a mooring rope that does not meet the standard, the risk of your cargo becoming loose and possibly damaged will increase, which will have a very negative impact on the person transporting the cargo. As one of the most professional PP rope/polypropylene rope suppliers and exporters, we provide quality-certified PP ropes at an affordable price, and also provide nylon ropes, polyester ropes, polyamide double braided ropes, etc. Our mooring ropes are widely appreciated by customers for their high durability, best surface treatment and longer shelf life.

Features of PP Ropes

- Anticorrosive Material – Polypropylene is a good load limiting material because it is completely anticorrosive! This is a huge benefit for long-term use and storage, especially when used outdoors, where the possibility of it being soaked frequently is high. Other types of ropes, such as hemp rope, will not be able to withstand this condition due to bacterial growth. On the other hand, polypropylene rope can maintain its performance and strength for a longer time.

- Floating Ability – At first, this may not seem like a big advantage, but if you need a rope for boating, a rope that won’t float won’t last long at all. Since polypropylene can be easily recycled, it has become a natural choice for ropes used in and under water. Its bright color also makes it easy to be seen in harsh environmental weather, low light conditions, or under the dark background of water.

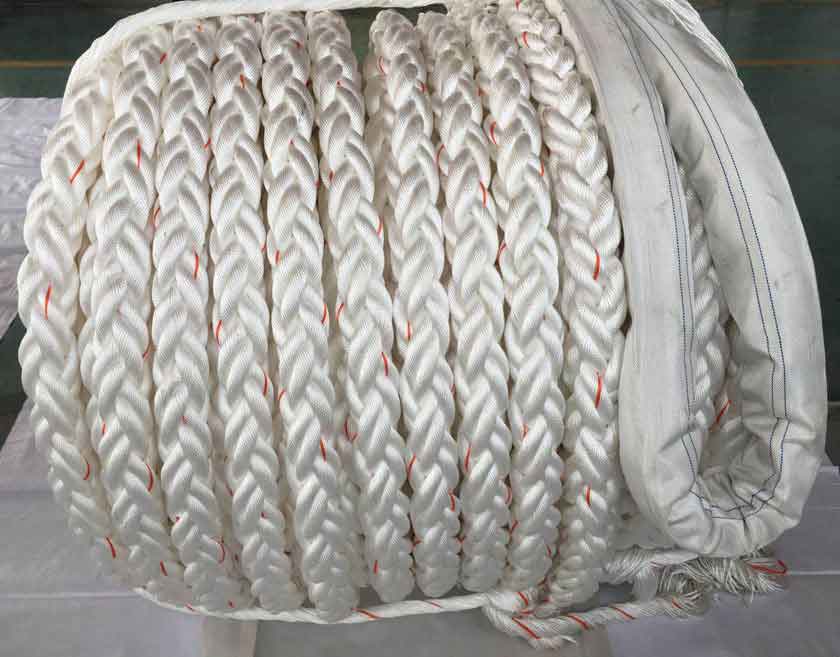

- Robust Structure – One of the most significant benefits of rope is the way it is manufactured. Polypropylene is a strong polymer that can withstand many types of glues and solvents. The rope is woven from three strands of yarn, which is very durable and strong. Polypropylene also has a higher melting point than most common polymers, making it resistant to heat and friction. It will not break, which makes it more user-friendly and can extend its lifespan even when knots and untied frequently occur.

- Light Weight – Low density textile fiber (only 0.91 g/cm³). The rope made of PP is light enough to float on the water without absorbing water. Even in a humid environment, they can remain soft.

- Multiple Usage – Polypropylene rope has a wide range of diameters, ranging from 4 mm to 32 mm. This diameter determines the rope’s ability in terms of strength and load capacity. Due to such a wide range of options, the product is versatile and adaptable, and can be used in various household and commercial applications.

Applications of PP Ropes

- Marine: marine anchor rope, guide rope, sling, whiplash, lifeline, cargo net, etc.

- Fisheries: Anchor ropes, floating ropes, tow ropes for cultured pearls and oysters, etc.

Specification of PP Ropes – 8 strands &12 strands

|

Size |

Weight |

Breaking Strength ISO MBF |

Breaking Strength MEG4 LDBF |

||||

|

mm Dia. |

Inch Cir. |

g/m |

kg/220m |

KN |

Ton |

KN |

Ton |

|

24 |

3 |

260 |

57.2 |

93 |

9.5 |

84 |

8.6 |

|

28 |

3-1/2 |

355 |

78.1 |

124 |

12.6 |

111 |

11.4 |

|

32 |

4 |

460 |

101.2 |

163 |

16.7 |

147 |

15 |

|

36 |

4-1/2 |

586 |

128.9 |

198 |

20.2 |

179 |

18.2 |

|

40 |

5 |

718 |

158.0 |

245 |

25.0 |

221 |

22.5 |

|

44 |

5-1/2 |

881 |

193.8 |

292 |

29.8 |

263 |

26.8 |

|

45 |

5-5/8 |

924 |

20. |

307 |

31.3 |

276 |

28.2 |

|

48 |

6 |

1040 |

228.8 |

350 |

35.7 |

315 |

32.1 |

|

50 |

6-1/4 |

1130 |

248.6 |

371 |

42.3 |

334 |

34.1 |

|

52 |

6-1/2 |

1220 |

268.4 |

414 |

45.5 |

373 |

38.0 |

|

55 |

6-7/8 |

1380 |

303.6 |

446 |

47.6 |

401 |

40.9 |

|

56 |

7 |

1420 |

312.4 |

467 |

53.6 |

420 |

42.9 |

|

60 |

7-1/2 |

1630 |

358.6 |

525 |

59.5 |

473 |

48.2 |

|

64 |

8 |

1850 |

407.0 |

583 |

61.4 |

525 |

53.6 |

|

65 |

8-1/8 |

1924 |

423.3 |

602 |

67.3 |

542 |

55.3 |

* MBF: Min. Breaking Force according to ISO2307.

* LDBF: Line Design Break Force according to OCIMF MEG4 appendix B

* Other sizes are available upon request