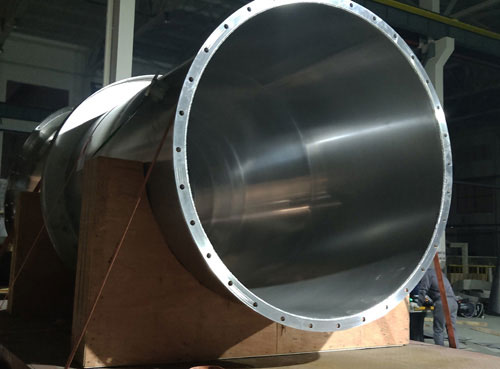

The prefabricated components of a piping system are called pipe spools. The pipe spools are made up of three components: Pipes, Flanges and Fittings. The spools are mounted during the fabrication and delivered pre-mounted, to make an assembly with hoists, measuring devices, and other joining devices easier. Briefly, the pipe spools connect long pipes with flanges at the tips and have to be positioned properly to make sure they can withstand the weight and force of the structure.

The prefabricated pipe spools are mainly made of stainless steel. Its good steel adhesion provides superior long-term corrosion strength and pipeline protection in a low-temperature environment. Higher adhesive properties ensure excellent cathodic dissolving resistance, which reduces the total cost of cathodic protection during pipeline operation.

Ship construction and maintenance includes a wide range of projects and involves intensive piping to connect a variety of equipment and transport fluid and gas. This is where the prefabricated pipe spools exhibit an important role.

Boomarine is a professional marine equipment supplier, we have the capability to offer prefabricated piping spools upon the design drawings and requirements, including pipe, fittings, flanges, and prefabricate them into “spools” suitable for field assembly. Boomarine supplies all grades of stainless steel flanged spool pieces such as SS2205, SS316, SS304L, 254SMo, etc.

Features of Prefabricated Pipe Spools

- Welding method: Plasma welding

- Inspection: PT or RT & Pressure Test

- Custom made as per provided drawings

Advantages of pipe spools prefabrication:

Parts are constructed as “components” and “sub-components” before needed, so they can be installed on demand rather than on-site manufacturing. It is convenient for the coordination and control of quality, schedule and management in a fixed area, reduces the workload of on-site prefabrication and on-site installation, and greatly improves the installation, quality and schedule of the whole project. And craft workers are exposed less to the more adverse working environment of a construction site, improving safety performance.

Why Pipe Spools Are Pre-fabricated?

The prefabricated pipeline shaft is important because shipbuilding and other maritime industries need intensive pipes. Due to the limitations of field space, and this type of pipe connects a variety of equipment and conveys process fluid and gas. Therefore, industrial construction projects rely heavily on offsite fabrication and assembly.

Shop pre-fabrication of pipe spools is a proven means for reducing field installation costs while providing the highest quality in the products fabricated.

Pipe spools are often flanged to facilitate the connection to other spools. The fabrication of these spools is normally performed by specialist fabrication companies which are equipped with the required infrastructure. The specialist fabricators work under a defined set of quality management criteria to ensure the accuracy of fabrication in order to achieve the proper fit at the site and to maintain the required technical parameters defined by the client.

Fabricated Pipe Spool Parts

- Reducer – Concentric reducer, eccentric reducer

- Pipes – Seamless/welded

- Tee – Equal Tee, Unequal Tee

- Flanges – Blind, weld neck, slip-on, etc.

- Elbow – 90° / 45° / 180°

Modern pipe spools prefabrication:

The use of QSPT pipeline prefabrication production line or QSPT software, equipment, advanced pipeline prefabrication automation equipment can be used to improve the efficiency and quality of pipeline prefabrication, maximize the advantages of pipeline prefabrication.