Marine Roller Fender

Roller fender is a type of dock marine fender, made of stainless steel and composites, rolling resistance is very low, and almost requires no maintenance.

Roller fender is usually used to guide the ship to enter space-restricted areas. They are widely installed on the walls of dry docks and other restricted channels to help guide ships and prevent hull damage. It is also used to require lower energy capacity berth angles and lock ports.

Roller fender is also used to mount on a fixed axis supported by a special frame. It has a sliding shaft with a post latent wheel to absorb as large energy as possible. The roller fender has a fixed axis that makes it very suitable for the pier and the wall of the lock. The main characteristic of the marine roller fender is that when the ship is berthing, the fender can rotate with the ship’s displacement, and produce a certain deformation to absorb part of the impact energy of the ship. Roller fender is suitable for docks, locks, all kinds of restricted waterways, and protruding corners of docks.

Boomarine is a professional marine equipment manufacturer and exporter, our marine rubber fender has been recognized by many international buyers as reliable products. We also offer class certificates such as BV, LR, ABS, NK. If you are interested in our products or if you have any questions, please feel free to contact us for more details.

Features of Marine Roller Fender:

- Low reaction force and high energy absorption

- Low scrolling resistance

- Low maintenance frame design

- High bearing capacity

- Usually maintenance-free

- Composite bearing removes contact with metals and metals

Applications of Marine Roller Fender:

- Water gates

- Entrance to ship locks

- Dry-dock entrances and walls

- Some exposed corners and entrances

- Other narrow or exposed areas.

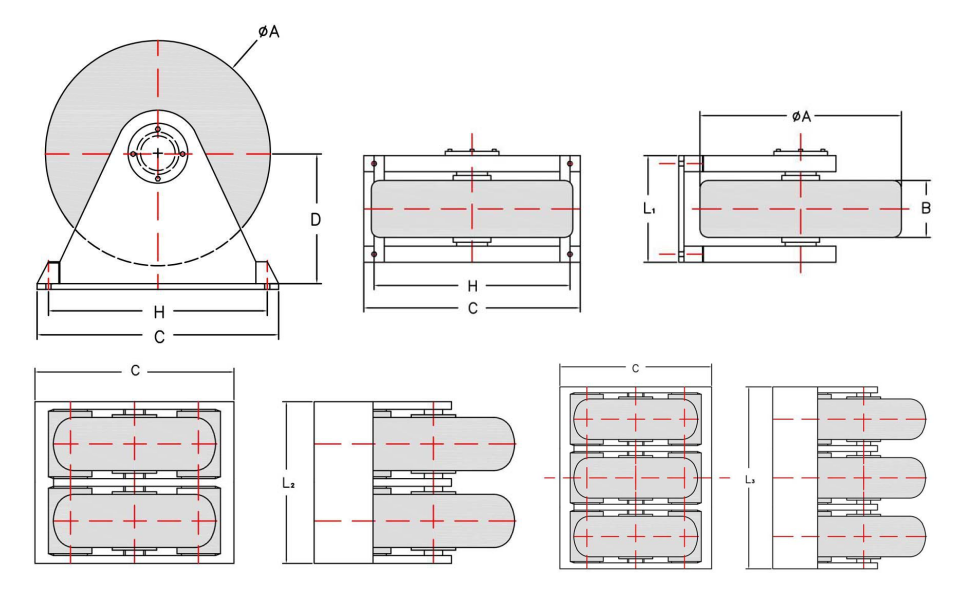

Dimensions: (unit: mm, kgs) – Download PDF at this page for more details

What types of marine roller fenders can we provide?

Our Roller Fenders have two types, roller fender type A and roller fender type B.

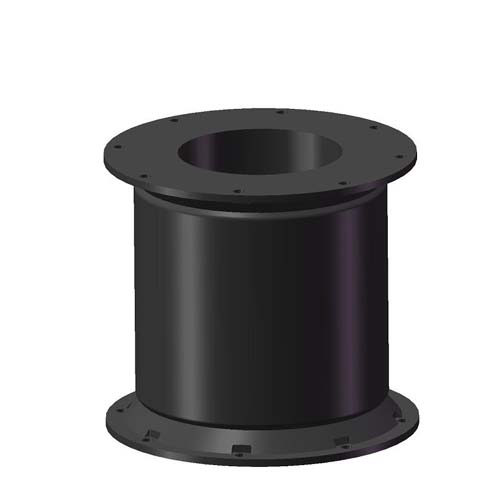

Type A Roller Fener

Type A roller fender can rotate with 20% deflection during berthing which makes it can absorb part of impact energy.

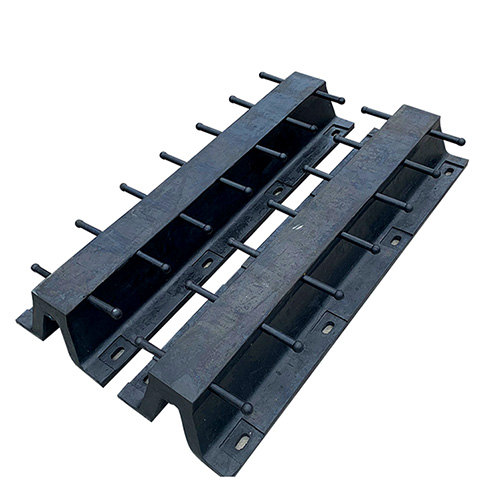

Type B Roller Fener

Type B roller fender can rotate on three fixed axles, it has a sliding axle in front of two idler rollers to absorb the greatest possible energy during compression of the wheel into the casing.

| Type (AxB) | R1 | R2 | R3 | ||||||||

| A | B | C | D | L1 | H | Weight | L2 | Weight | L3 | Weight | |

| 600×200 | 600 | 200 | 695 | 320 | 420 | 620 | 127 | 770 | 245 | 1120 | 365 |

| 750×250 | 750 | 250 | 870 | 400 | 510 | 775 | 249 | 935 | 501 | 1360 | 735 |

| 900×300 | 900 | 300 | 1040 | 480 | 610 | 930 | 465 | 1120 | 878 | 1630 | 1291 |

| 1200×400 | 1200 | 400 | 1380 | 640 | 820 | 1240 | 1045 | 1500 | 2041 | 2180 | 3005 |

| 1500×500 | 1500 | 500 | 1740 | 800 | 1010 | 1550 | 2011 | 1850 | 3915 | 2690 | 5784 |

| 1800×600 | 1800 | 600 | 2080 | 960 | 1210 | 1860 | 3441 | 2215 | 6701 | 3220 | 9891 |

| 2100×700 | 2100 | 700 | 2440 | 1155 | 1410 | 2205 | 5610 | 2590 | 10925 | 3770 | 15895 |

| 2400×800 | 2400 | 800 | 2770 | 1280 | 1610 | 2480 | 8115 | 2950 | 15701 | 4290 | 23300 |

Roller fenders can be installed in various combinations, such as:

- Stack double or triple fender can cover a larger height of the tidal area.

- Parallel to guide the vessel through a narrow channel.

- Tilt installation to accommodate hull.

Product Photos: