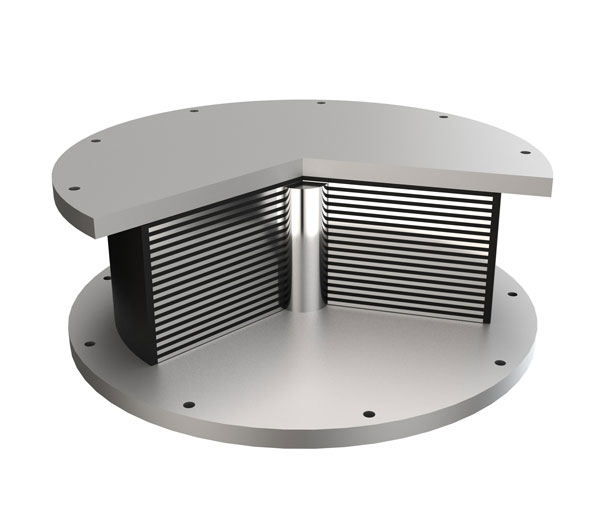

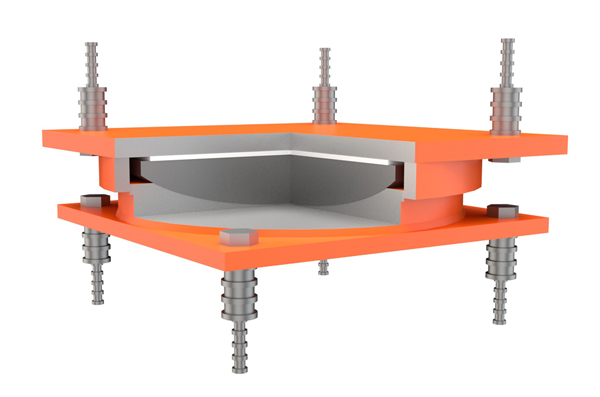

Spherical bridge bearing is a structural bearing, which consists of a precision-machined steel component assembly with a spherical concave and convex element in the center. The surface of the dome is polished to maintain the lowest possible friction, thus allowing rotation by bending and sliding.

The spherical bridge bearing has a high-strength steel body and is designed for high vertical, horizontal and lateral loads, and where large rotational structural displacements need to be accommodated. To provide movement capability, the bearings can be combined with flat sliding elements, guides and limiting rings.

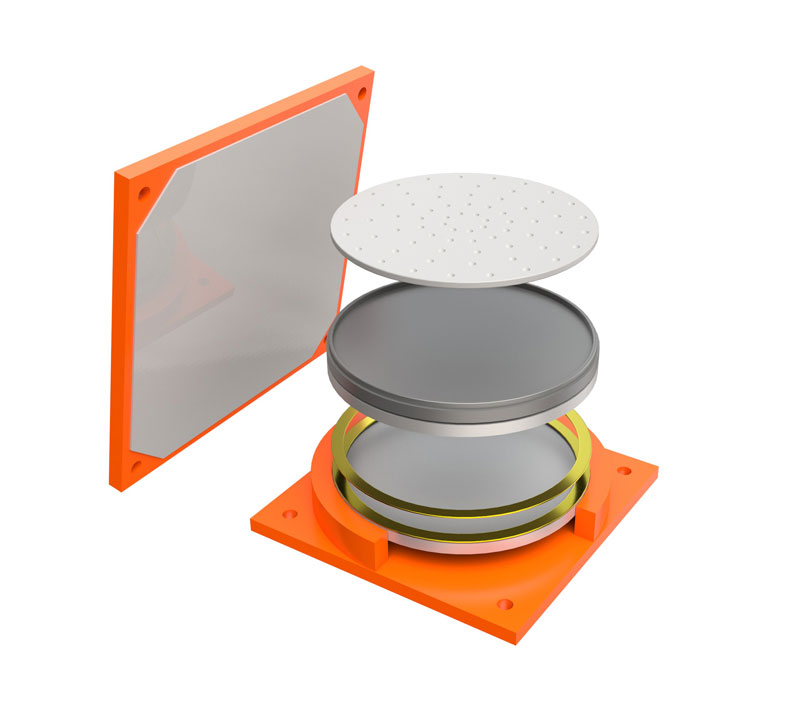

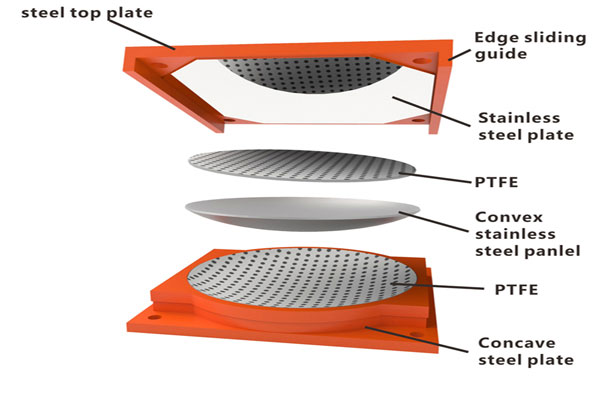

The spherical bearing is composed of an upper steel plate, a lower steel plate, a convex middle plate, and two PTFE plates of different shapes, same as pot bridge bearing, the spherical bearing has fixed type, guided sliding type, and free sliding type.

The middle of the lower steel plate is a concave spherical surface, corresponding to the convex intermediate plate, lined with an arc PTFE plate between the two, through the spherical surface sliding to meet the rotation of the beam end.

The stainless steel plate on the upper plate and another PTFE plate on the middle plate constitute the second sliding surface to complete the expansion and displacement of the beam body due to temperature differences and other factors.

The spherical bridge bearing supplied by Boomarine not only has the characteristics of large bearing capacity and horizontal displacement of the pot type rubber bearing, but also can adapt to the need for large rotation angle, and is suitable for wide bridge and curved bridges. Because the pressure parts do not use rubber parts, there is no brittle aging at low temperatures and other effects, so it is especially suitable for low-temperature areas. In addition spherical bridge bearings, we also supply other types of bridge bearings. If you are interested in our products, please feel free to contact us.

Specification of Spherical Bridge Bearing

| Material | Steel and PTFE sliding plate. |

| Working temperature range |

Normal type: -25 °C to +60 °C. Cold resistant type: -40 °C to +60 °C. |

| Friction coefficient |

(In condition of PTFE layer with silicon grease lubrication and stresses about 30 MPa) Normal temperature: 0.03. Low temperature: 0.05. |

| Bearing horizontal force |

Guided type: Horizontal force is 10% vertical bearing capacity. Fixed type: horizontal force is 10% vertical bearing capacity. |

| Vertical bearing capacity | 1000, 1500, 2000, 2500, 3000, 4000, 5000, 6000, 8000, 9000, 10000, 12500, 15000, 17500, 2000 kN. |

| Displacement |

In longitudinal direction 1000–2500 kN, 50/100 mm. 3000–20000 kN, 50/100/150 mm. In transverse direction: ± 40 mm. |

Features of Spherical Bridge Bearing

- Accommodates high rotation and any directional movement.

- High-strength stainless steel makes it durable.

- Reliable quality, consistent rotation performance.

- Very low sliding friction.

- Self-alignment capability.

- Easy to install.

- High durability and low maintenance cost.

- More suitable for low temperature areas.

- Can be designed with braided PTFE or sheet PTFE depending on desired properties.

Applications of Spherical Bridge Bearing

- Applicable bridges: RC bridges, PC bridges, steel bridges, railway bridges, easy-falling bridges, slanted bridges at both ends, etc.

- Applicable bridge conditions: large-angle bridges, wide-curved bridges, large torsion bridges, low-temperature bridges below -30℃, etc.

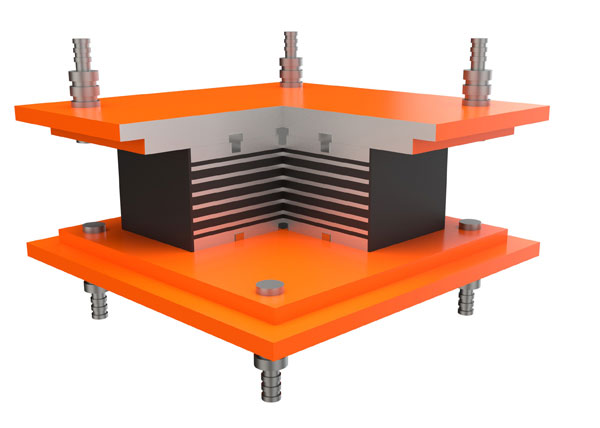

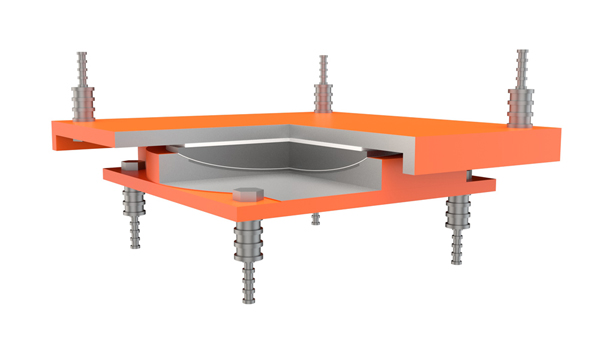

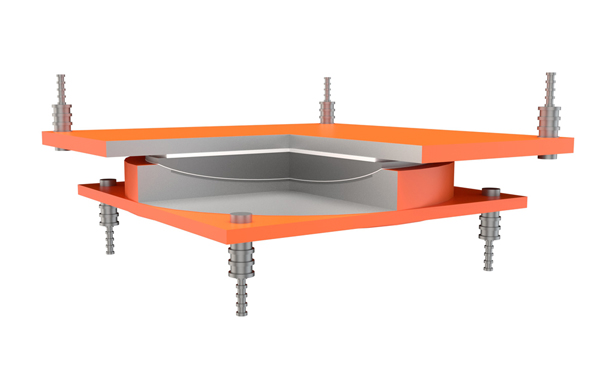

Types: the spherical bridge bearings include fixed type, guided type, and free sliding type.

Fixed bearing – vertical rotation performance

Guided sliding spherical bearing – vertical rotation and longitudinal sliding performance

Free sliding spherical bearing – Vertical rotation, longitudinal and horizontal sliding performance

Spherical Bridge Bearing Maintenance

The bearing is inspected and maintained regularly every year during its use:

- Check whether the bearing anchor bolt is cut and whether the bearing rubber sealing ring is cracked or aging.

- Check whether the relative displacement of the bearing is uniform, and record the displacement of the bearing one by one.

- Remove the debris and dust near the bearing, and wipe the dust on the surface of stainless steel carefully with cotton thread.

- Loosen the foundation nut once, clean and oil the nut to avoid rust, and then tighten it.

- Check and fixed point check the height of the bearing change, in order to check the wear of PTFE in the bearing, when the height of the bearing change is more than 3mm, the rubber sealing ring should be removed, check the PTFE plate.

- Periodically paint the bearing steel parts for rust prevention (except stainless steel sliding surface).