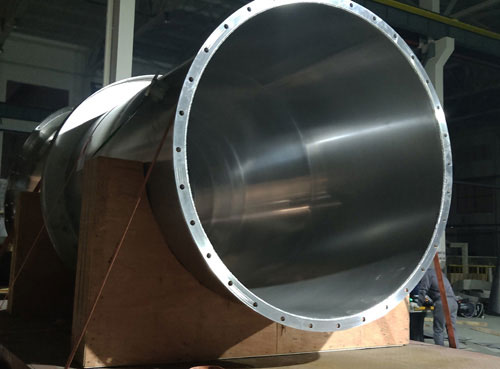

The Stainless Steel Pipe Spool is a relatively short component, consisting of a pre-determined length of pipe welded to a specified pipe fitting (tee, elbow or reducer) or valve (gate or ball). The flange is usually welded to each end of the pipe.

Due to the excellent corrosion resistance of stainless steel, the pipeline is not easy to rust, damage or accumulate debris by wear. Electrical steel has low maintenance costs. And due to its corrosion resistance, it is unlikely that stainless steel pipes will need to be replaced for decades.

The stainless steel pipe spool is of prefabricated length for easy use of Tri-Clamp fittings. These pipes will construct a process line in conjunction with other Tri-Clamp fittings, clamps and gaskets, eliminating the need to weld and produce on-site, and saving time significantly.

Boomarine is a leading supplier of marine equipment in China, and we always believe in serving customers with the highest quality products. We provide complete piping solutions. We have a dedicated design, engineering and manufacturing team that can provide first-class pipe spools. As a one-stop solution provider, we do our best to meet all the pipeline requirements of our customers.

Stainless Steel Pipe Spools Specifications:

| Grade | ASTM A403 WP Gr. 304, 304L, 304H, 309, 310, 316, 316L, 316Ti, 317L, 321, 347, 347H, 904L |

| Standard | ASTM, ASME and ANSI |

| Size | 0.5″ to 24″ |

| Schedule/Wall Thickness | 10s/3 mm to XXS/70 mm |

Stainless Steel Pipe Spools Features:

- Welding method: Plasma welding.

- Inspection: PT or RT & Pressure Test.

- Destructive and nondestructive examination of welds.

- Custom made as per provided drawings.

Custom Pipe Spools Main Stainless Steel Materials:

Specifications:

| Material & Grade | Stainless Steel ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L |

| Dimension | ASME B16.9, ANSI B16.9, ASME B16.28, ANSI B16.28, ANSI B16.25 |

Equivalent Grades:

| STANDARD | WERKSTOFF NR. | UNS | JIS | BS | GOST | AFNOR | EN |

| SS 304 | 1.4301 | S30400 | SUS 304 | 304S31 | 08?18?10 | Z7CN18?09 | X5CrNi18-10 |

| SS 304L | 1.4306/1.4307 | S30403 | SUS 304L | 304S11 | 03?18?11 | Z3CN18?10 | X2CrNi18-9 / X2CrNi19-11 |

Chemical Composition:

| Element | Ni | C | Mn | P | S | Si | Cr |

| SS 304 | 8.0 – 11.0 | 0.08 | 2.0 max | 0.045 max | 0.03 max | 1.0 max | 18.0 – 20.0 |

| SS 304L | 8.0 – 13.0 | 0.35 | 2.0 max | 0.045 max | 0.03 max | 1.0 max | 18.0 – 20.0 |

Mechanical & Physical Properties:

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| SS 304 | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

| SS 304L | 8.0 g/cm3 | 1400 °C (2550 °F) | Psi – 75000 , MPa – 515 | Psi – 30000 , MPa – 205 | 35 % |

Fabricated Pipe Spool Parts

- Reducer – Concentric reducer, eccentric reducer

- Pipes – Seamless/Welded

- Tee – Equal Tee, Unequal Tee

- Flanges – Blind, weld neck, slip-on, etc.

- Elbow – 90° / 45° / 180°