UHMW-PE is an extremely tough plastic with high wear resistance. It is the strongest and toughest fender of all polyethylene grades used in marine applications. Even as a finishing material, it is lighter and more durable than steel. Polyethylene’s versatility has made it a common material for endless industrial applications that require toughness, low friction and resistance to chemicals.

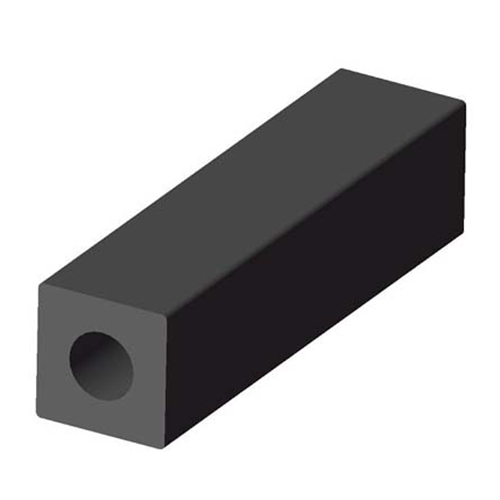

UHMW-PE sliding fender will not rot, nor will it be affected by marine borers. It does not contain particles, so it will not chip or crush, and can be easily cut, drilled and processed. The thickness of our UHMW-PE sliding fenders is usually 2 mm to 400 mm, and the size ranges from 1,000 x 1,000 mm to 2000 mm x 6000 mm. It can also be customized according to your requirements.

UHMW-PE sliding fender is usually used in waterways, ports, wharf construction, pontoon bridges and composite fenders. The combination of excellent impact strength and low friction and wear resistance makes it a popular choice in the marine industry. Its applications include UHMW wear strips, chain guides, and fender pads for marine ports. As a professional marine fender manufacturer and supplier, Boomarine can provide you with tailor-made marine fender solutions.

Applications of UHMW-PE Sliding Fender:

- Sliding boards

- Lock walls & entrances

- Quay wall protection

- Pile Protection

- Pier protection

- Quick start lifeboat slide

- Fender panel surface pad

- Friction strip of fender pile

- Floating bridge guide pile bearing

- Belts for small workboats

UHMW-PE Sliding Fender Characteristics:

- Low friction coefficient

- High abrasion resistance

- UV and ozone resistant

- Reduced conductivity optional

- 100% recyclable & non-rotting

- Resists marine borers

- Easy to cut and drill

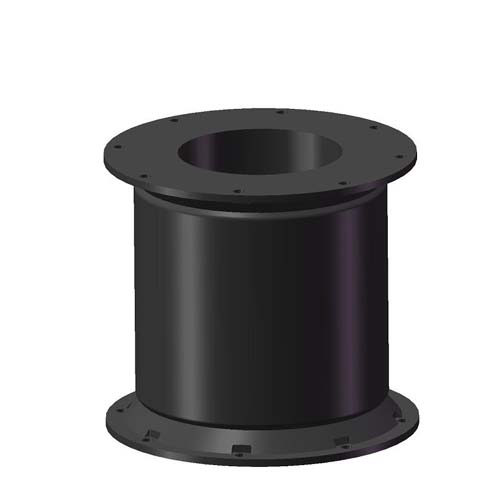

Marine Fender Face Pad:

How to choose the right UHMW-PE sliding fenders?

You can use our UHMW-PE sliding fenders alone as a low-key protective barrier. These fenders are especially suitable for docks or any docking environment. Because the low friction properties provided by the material greatly reduce the damage and wear to the ship and the fender itself.

You can also combine our UHMW-PE sliding fenders with existing marine rubber fenders to extend service life and add new performance. For example, you can install this product as a panel on an arch fender to provide a low-friction alternative. This increases the functionality of the rubber fender and allows you to replace the panel at a fraction of the cost of a new fender.

The standard color of our UHMW-PE sliding fender is black. Other colors are available upon request, such as green, yellow, white or red.

Technical Properties of UHMW-PE Sheet:

|

Physical Properties |

|||

|

Test Method |

Item |

Unit |

Value |

|

ASTM D792 |

Density |

g/cm³ |

0.93-0.97 |

|

ASTM D570 |

Water absorption |

? |

?0.01 |

|

Mechanical Properties |

|||

|

ASTM D638 |

Tensile strength |

Mpa |

40 |

|

ASTM D638 |

Elongation at break |

% |

300 |

|

ASTM D790 |

Flexural strength |

Mpa |

24 |

|

ASTM D695 |

Compression strength |

Mpa |

21 |

|

ASTM D2240 |

Hardness, shore D |

– |

D66 |

|

– |

Coefficient of friction |

– |

0.12 |

|

Thermal Properties |

|||

|

ASTM D648 |

Heat deflection temperature |

? |

47 |

|

ASTM D3412 |

Melting point |

? |

135 |

|

– |

Continuous service temperature |

? |

82 |

|

Electrical Properties |

|||

|

ASTM D257 |

Surface resistivity |

Ω-M |

?10^15 |

|

ASTM D150 |

Dielectric constant 106Hz |

– |

2.3 |

|

ASTM D257 |

Volume resistively |

Ω*cm |

?10^15 |

|

ASTM D604 |

Dielectric strength |

KV/mm |

45 |