Marine rubber fenders play a vital role in maritime safety. They help prevent ships from making costly mistakes when maneuvering near other ships or piers. Therefore, for those in the shipping industry, these fenders play a very important role in ensuring the safety of their assets.

In daily use, due to the frequent contact between the ship and ship, the ship and wharf, as the protective equipment of the ship, the fender will inevitably be subject to friction and collision, so it will inevitably be damaged to a certain extent. If the structure is damaged, the fender system will lose its protective function. Therefore, for long-term operation safety, regular maintenance and inspection must be carried out.

Reasons for damage to marine rubber fenders:

- The main reason for the cracking of the marine rubber fender is that the kinetic energy of the ship hitting the fender is too large, which exceeds the load that the rubber fender can withstand. The reason for the excess kinetic energy of the ship’s impact is the excessive speed and angle of the ship.

- When the berthing angle is large, the bow of the ship contacts the dock and the rubber fender before the middle of the hull, causing strong impact kinetic energy to concentrate on one or several fenders, causing damage to the rubber fender.

- One situation generally occurs on fixed V and D fenders. The main damage to the fender is corners, cracks and surface scratches. The main reason for this damage is the excessive friction between the rubber fender and the ship. When the ship arrives at a high tangential speed, the contact part between the rubber fender and the hull is forced to move forward with the ship due to excessive friction, causing the fender to be sheared and damaged.

- In addition, in mooring operations, the ship sometimes needs to move forwards and backward, and the ship swayed from side to side or up and down due to waves and currents. In this case, when the friction coefficient between the ship and the rubber fender is greater than 0.4 (for example, the mooring rope is too tight), the fender may be damaged.

How to maintain the marine fenders?

The maintenance of dock rubber fenders needs to be carried out according to different degrees. The fast-paced loading terminal does not allow long-term shutdown and maintenance. In order to properly resolve this contradiction, we can proceed from the following three aspects:

- Grasp the opportunity of barge berthing gaps and tidal fluctuations, and use every bit of time and space to repair. This method is suitable for maintenance tasks of small scale and small workload. The company’s construction is usually carried out by the maintenance team of the loading and unloading company. The construction period can be flexibly controlled in batches, without affecting production, and not subject to the limitation of the outsourcing contract period.

- For projects with large workloads, complex construction, and long maintenance time, outsourcing is generally appropriate. Since this process requires disassembly and installation of the fender, it takes a long time to release the dock.

- The most basic measure to strengthen inspection and maintenance work is to pay attention to usual inspection and maintenance, and the implementation of this work is essential to reduce maintenance.

After the fender system is installed and put into service, inspection shall be carried out each time after berthing of the first three ships and then monthly inspections are to be conducted.

Inspection Scope:

- Check the foot bolts for fender buffer installation and the bolts for fastening the frontal panel. Fasten them enough in case of any loose and then fix the fastening bolt and washer by spot welding.

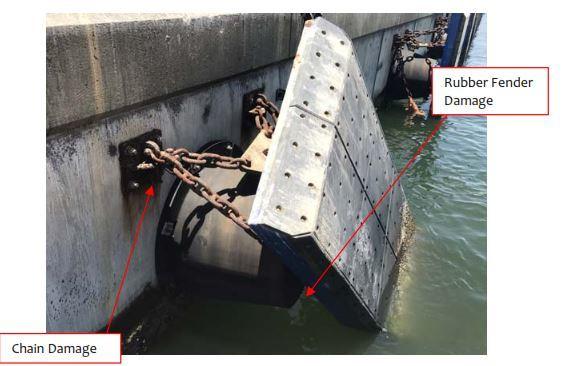

- Check the fender buffer for any breaks or cuts.

- Check the frontal panel for any dent, crack or corrosion. If does, please contact our company. Annual anti-corrosion treatment is to be carried out to the frontal panel to avoid rusting.

- Check the front panel for any inclination. The material accumulation in the inner part of the front panel may cause frontal inclination, so the accumulations shall be cleaned as much as possible.

- Check the front panel for any scratching or compression damage, replace the damaged pads in time.

- Check the concrete structure area where the fender system is installed for any crack appearance. If crack exists, contact the relevant department immediately for treatment.

- Check the elastic rubber parts for suspending the front panel to ensure they are under proper condition, replace any unpractical ones.