What is rubber fender?

Rubber fender, also known as rubber bumper, is installed on docks or ships to absorb the collision energy between ships and docks or ships when docking or mooring, so as to protect ships and docks from damage.

How to classify the rubber fenders?

Generally, the rubber fender can be divided into two categories according to the structure: solid rubber fender (non-floating type) and floating rubber fender.

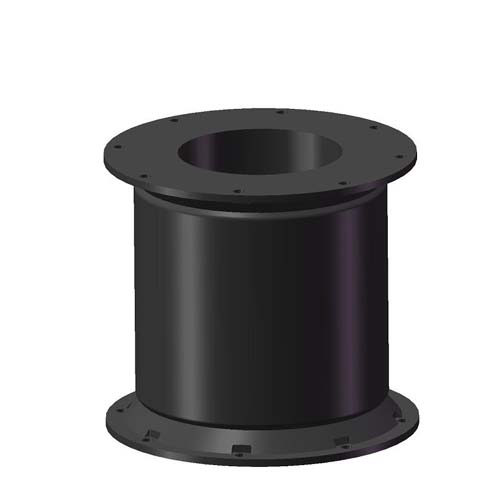

Solid rubber fender (non-floating type) is a kind of anti-collision equipment for wharf ships with a long history and a wide range of applications. According to the force of rubber fender, it can be divided into shear type, rotation type and compression type, etc. According to the structure of fender, solid rubber fender can be divided into D type, cone type, drum type, fan type, rectangle type, cylindrical type fender, etc.

Boomarine supplies many kinds of solid rubber fenders, the most popular types such as:

Floating rubber fender can float freely in the water, according to its internal buffer medium can be divided into inflatable rubber fender and foam-filled rubber fender.

The inflatable rubber fender uses compressed air as the medium, and the impact energy is consumed through work done by compressed air.

Foam-filled fender is also known as solid polyurethane fender. The internal buffer medium is mainly closed cell foaming materials, such as foamed EVA, foamed polyurethane and foamed rubber, etc.

What are the features and applications of rubber fenders?

Solid rubber fender has high energy absorption and reaction force, and also has the advantages of low cost, long service life, simple installation and maintenance, etc. It is a more protective device installed in docks and shipyards. It is widely used in Japan, Europe, America and Southeast Asian countries.

Floating rubber fender is a new type of fender equipment, compared with solid rubber fender, its main features are: large compression deformation, large energy absorption, small reaction force, self-floating, easy to install, etc. It is usually used in ship-to-ship, ship-to-wharf, barging and docking, etc. It is especially suitable for installation on wharf where the tide level changes a lot due to its self-floating feature. Filled rubber fenders are especially suitable for applications in harsh environments, such as offshore drilling platforms, due to their maintenance-free and long-life advantages.

Rubber fenders can not only protect the ship and the wharf, but also reduce the horizontal load acting on the wharf, improve the berthing capacity of the wharf, make the new wharf lighter and reduce the cost.

Rubber fenders come in a wide range of sizes. Regular size products can easily choose matching vulcanization equipment, but the investment in large vulcanization equipment required for super-sized products is too high, especially when the product batch is small, it is not cost-effective to invest in large vulcanization equipment.

What are the manufacturing standards of rubber fenders?

The industry standards used for solid rubber fenders are “HG/T 2866-2016 Rubber Fenders” and “GB/T 21537-2008 Conical Rubber Fenders”.

The industry standard used for pneumatic rubber fenders is the international ISO standard ISO17357:2002 “High pressure Floating pneumatic rubber fenders”.

Foam-filled floating rubber fender is a new product, there is no international standard and industry standard.

Properties of rubber fenders

| PROPERTIES | TEST METHOD | VALUES |

| Density (Specific Gravity) | DIN 53505 | 1200 kg/m3 |

| Tensile Strength | DIN 53504 | ≥16 MPa |

| Elongation at Break | DIN 53504 | ≥350% |

| Tear Resistance (23°C) | DIN 53507 | ≥80 N/cm |

| Abrasion Resistance | DIN 53516 | ≤100mm3 |

| Compression Set (24hrs @ 70°C) | DIN 53517 | ≤40% |

| Ozone Resistance (ppm 20% 72hrs @ 40°C) | ISO 143/1 | No cracking visible by eye |

| Minimum Temperature | – | -30°C |

| Maximum Temperature | – | +70°C |

The importance of quality and safety of rubber fenders

With the development of the global shipping industry, there are more and more demands for docks and marine fenders, and the requirements for fender performance are also getting higher and higher. Among them, rubber fenders are the most widely used due to their good toughness and impact resistance. At present, there are many manufacturers of rubber fenders in the world, and the products are mixed. In order to survive in the fierce market competition, some manufacturers unilaterally take low-price competition as the main means, do not strictly abide by relevant standards and processes, use low-quality raw materials or use too much recycled rubber to reduce the cost, which brings great hidden danger to the safety of dock and ship berthing.

Rubber fenders are mainly used for safety protection when ships are berthing at the quay for outfitting. If the ship collides due to the quality of the rubber fenders during outfitting at the dock, which results in damage to the hull, the ship will have to be reworked and repaired or even delayed. Although compared with ports, rubber fenders are not the main production facilities of shipbuilding enterprises, and shipyards also pay more attention to the cost-effectiveness of rubber fenders, but the product quality must not be ignored.

Manufacturers should consider the following important factors when designing and producing rubber fenders:

- Reaction force acting on hull and dock berthing members.

- The size of the deformation of the fender after absorbing the kinetic energy of the ship.

- Deformation of the fender produces a reaction force acting on the hull.

- Relative stiffness of fenders.

- Effectiveness of energy absorption of fenders during non-positive approach.

- The rate at which the fender slows the ship’s berthing speed.

- Friction coefficient between fender system and hull.

- Capital investment and maintenance costs of fender systems and support members.

- The contact method between the hull and the fender, etc.

Users can choose different types of rubber fenders according to the actual situation. Except for tugboats and small ships, large tonnage ships are generally not equipped with solid rubber fenders, and mainly use inflatable rubber fenders to protect the quay and hull when berthing.

Boomarine is a professional supplier and manufacturer of rubber fenders. Boomarine supplies the best quality rubber fenders. Mold injection type and extruded type rubber fenders are available from our company. We supply dockside rubber fenders, pneumatic fenders, foam-filled fenders, and vessel launching airbags. If you have any needs, please feel free to contact us.