What do you know about Ship Airbag Launching Technology?

The ship airbag launching technology is developed on the basis of the traditional slide launching technology. It uses the flexible airbag to replace the slide and skateboard, and overcomes many shortcomings of the traditional slide launching.

The flexible airbag is like an elastic cushion, which enables the hull to pitch freely during the launching process, maintaining a large contact area under the hull, so that the force of the hull is very moderate, so that the structure of the hull, the surface of the paint will not be damaged. Boomarine’s ship launching airbag is specially developed for ship launching technology. Its main function is to carry the ship launching or towing the ship uphill, with extremely high load capacity, wear resistance and seawater corrosion resistance. This heavy-duty airbag is widely used in the handling of huge building modules, salvage shipwrecks and disaster relief, storage and transportation of gas or liquid containers, erection of floating Bridges and water pipelines and other fields of operation.

The technology of airbag launching is also called “flexible launching technology“. The flexibility of the airbag allows the ship to launch as long as there is level ground, greatly improving the flexibility of using this technology.

Compared with the traditional slipway launching technology, what are the advantages of airbag launching technology?

- It saves the capital investment of shipyard construction. In the construction of shipyard infrastructure, the investment in launching facilities, such as traditional launching slides and launching works, is staggering.

- Shipyards using airbag launching technology only need to build simple ramps, simple facilities and no complex launching works.

How to Apply the Airbag in Launching Process of Ordinary Medium-sized Ship?

1. After calculation, prepare enough rolling airbags, lifting airbags, traction winches, air compressors, etc. Airbag should be tested before use (charging pressure can be 1.25 times the safe working pressure). If air leakage is found, it should be repaired before use.

2. Arrange the path of the moving ship, including the slipway to the ramp. Must be smooth, remove debris, pay special attention to the sharp hard nails on the ground, sharp stones must be clean, to prevent punctured airbags, ramps should be sufficient length and depth in the water.

3. Polish off all burrs on castings such as protruding corners, beauty frames and stern posts on the bottom of the ship.

4. Tie the cable of the towing winch to the hull.

5. Close all sea valves and fix rudder and propeller.

6. Remove all piers and fill in rolling airbags. There are many ways, two of which are provided below. Users should choose one according to the weight of the ship and the number of airbags and other equipment conditions.

6.1 For ships with small dead weight, the bearing capacity of the airbag can lift all the weight out of the pier, and the pier can be removed directly and the rolling airbag can be filled.

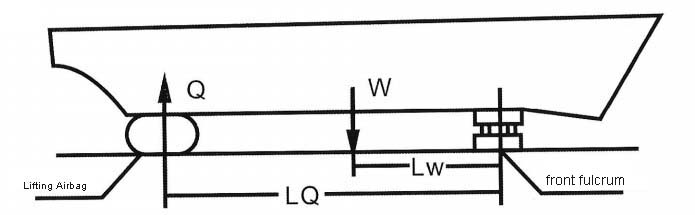

6.2 For ships with large dead weight, the bottom can be lifted by lifting bags (or their combined forces) at the stern. For this purpose, the best position of the fore fulcrum and lifting bags must be selected first. As can be seen from the figure, the closer the front fulcrum is to the center of gravity, the better, but the pier wood before the front fulcrum is too much, and the workload of artificial pier dismantling is too large. Therefore, a reasonable location should be obtained according to the length of the ship and other factors. The lifting bag should be taken at the tail end as far as possible, but it needs to see the stern alignment. Some of the ground in the bottom of the ship is too high or too thin. The lifting force of the lifting bag is too small, so it is better to move forward appropriately.

Therefore, the situation of each ship is different, and the best forward fulcrum and airbag position must be selected after specific calculation to meet the formula:

- Q* LQ > W * Lw

- Where: Q – lifting force of lifting bag

- W – Deadweight of vessel

- LQ – Distance from lifting force center of lifting airbag to the front fulcrum

- LW – distance from ship’s center of gravity to forwarding fulcrum

6.3 First remove all wooden piers at the lifting airbag and in front of the front fulcrum. Add a lifting bag and inflate, stopping when the bottom of the boat is slightly off the pier. Remove the pier from the middle to the tail one by one. According to the planned position of the rolling airbag, as long as the pier wood at the section is removed, immediately fill the section of the rolling airbag, and properly inflate, and then a backward pier, in turn, remove all the tail pier wood at the same time also fill the rolling airbag.

6.4 Remove the pier wood from midship to forward fulcrum and fill all forward rolling airbags by adjusting the pressure inside the aft filled airbag or by a similar method as above. For the sake of safety, an appropriate amount of loose pier should be added between the filled airbags at any time, and this part of the pier can be removed when the final rolling airbags can bear the weight of the ship. In addition, when dismantling the same section of a wooden pier, the middle should be removed first and then the two sides. When dismantling the outermost pier, workers should try to work outside the board.

7. Adjust the internal pressure of each airbag to make the bottom of the ship fall to an appropriate working height and keep the ship moving without touching the ground. It is generally advisable for small ships between 0.2-0.3m.

8. All airbags should be aligned with the center of the hull and perpendicular to the launching direction.

9. Start the traction winch to release the steel cable slowly, and the hull begins to move. When the first airbag at the head breaks away from the bottom of the ship, it is immediately lifted to the tail, and the airbag is fed at the spacing of the airbag in the calculation book.

10. Repeat the appeal process, gradually move the boat to the water’s edge, and seal off the river when the airbag cannot be fed.

11. Evacuate the dangerous area, inform the ship’s staff to get ready, when the water depth and other conditions are enough, order to cut the cable or unhook the ship to quickly launch. If the river is too narrow to launch quickly, a winch can be used to release the rope slowly and let the boat enter the water slowly.

12. For some larger vessels, it may be necessary to install skid stops.

13. Recycle airbags. And if there are some damages to your airbags, you can also repair them. You can refer to this article “5 Steps to Repair a Ship Launching Airbag”.

Are there any disadvantages to using “airbags”?

The ship airbag launching technology cannot be used for the side launching of large ships, so it is subject to certain restrictions on ship launching. And it requires more calculations for the launching process.

Summary

Ship launching with rubber airbags is an innovative technology that is widely used in the shipping industry. The technology is reliable, safe and is a good investment for shipyards. Ship launching airbags provide a perfect solution for lightships. Their strength, durability and excellent resistance to extreme conditions make them ideal for launching airbags on ships. As a leading supplier of marine equipment in China, the entire production process of ship airbags provided by Boomarine is under the control of ISO 9001:2008. From raw materials to highly skilled production processes, our engineering team is constantly improving. The manufacturing and testing of Boomarine rubber rollers comply with ISO 14409, and have obtained CCS, LR, DNV certifications.