What is bridge bearing?

Bridge bearing is an important structural component to connect the bridge superstructure and substructure, located between the bridge and the mat stone, it can transfer the load and deformation (displacement and corner) borne by the bridge superstructure to the bridge substructure reliably, and is an important force transmission device of the bridge. There are two kinds of fixed bearing and movable bearing. Bridge engineering commonly used bearing forms include: linoleum or flat bearing, plate rubber bearing, spherical bearing, steel bearing and special bearing, etc.

Bridge bearing construction should be in line with the theoretical calculation of the upper structure, such as bearing pressure through a fixed point of transmission, bearing should be designed to allow only the structure end rotation and can not move the fixed bearing. If the bearing pressure through a fixed point and the role is in a certain direction of transmission, should be designed to both rotate and can move the movable bearing. Beam bridge bearing has horizontal two-way fixed bearing (i.e. fixed bearing), horizontal two-way movable bearing (or two-way movable bearing), horizontal always fixed always movable bearing (i.e. movable bearing) three. its arrangement is according to the width of the bridge.

Classification of bridge bearings

They are classified according to the possibility of deformation, materials used, and structural form.

1. Classification according to the possibility of bearing deformation

(1) Fixed bearing;

(2) Single activity bearing;

(3) Multiple activity bearing.

2. Classification according to the materials used in bearing

(1) Steel bearing: flat bearing, arc bearing, rocker bearing, roller bearing.

(2) Whether there is a sliding capacity to divide the bearing: sliding bearing, fixed bearing.

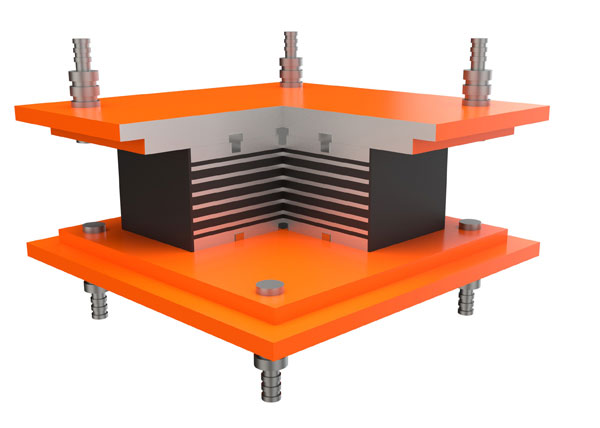

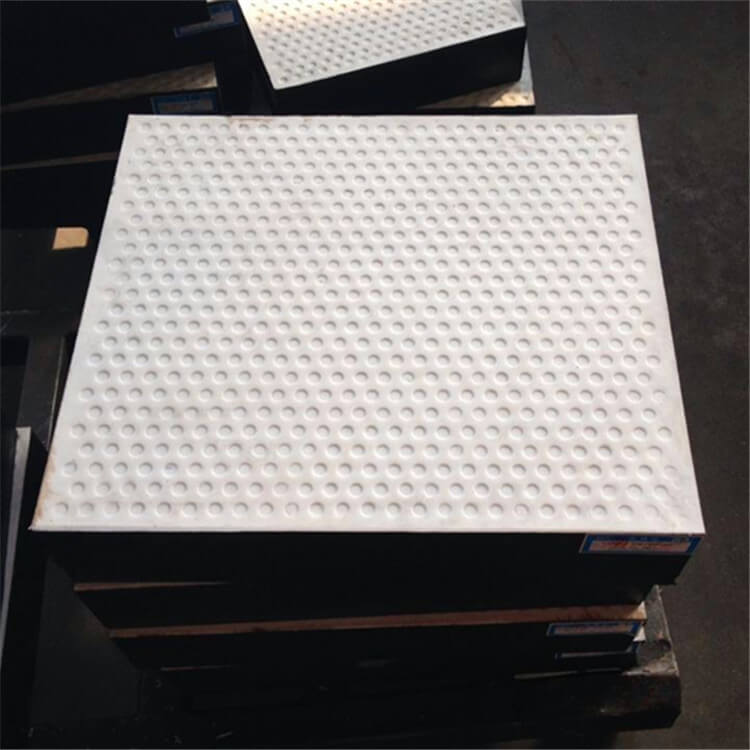

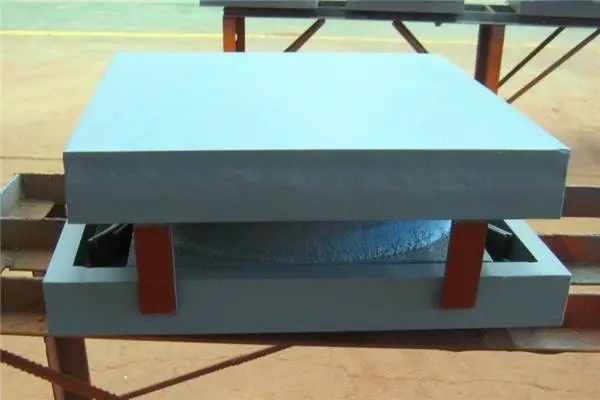

(3) Rubber bearings: plate rubber bearings (including PTFE sliding plate rubber bearings), basin rubber bearings, lead rubber bearings, high damping vibration isolation rubber bearings.

3. Classification according to the structural form of bearing

(1) Arc bearing;

(2) Rocker bearing;

(3) Roller bearing;

(4) Plate rubber bearing and PTFE rubber bearing;

(5) Pot type rubber bearing;

(6) Spherical steel bearing;

(7) Tension and compression bearing, etc.

There are many types of bridge bearings, which are mainly selected according to the support reaction force, span, building height and expected displacement.

The traditional common bridge bearings are: bedding bearing, flat bearing, arc bearing, rocking shaft bearing, hinged fixed bearing and hinged roller bearing, etc.

① Bedding bearing: Made of linoleum or asbestos sheet to support the superstructure, used for spans less than 6 meters (railroad bridge) or 10 meters (highway bridge) of simple support plate bridge and beam bridge.

② Plate bearing: By the upper and lower two flat cast steel plates (seat plate), for span less than 8 meters or 12 meters of beam bridge. Between the seat plate, such as the addition of pins, can constitute a fixed bearing.

③ Arc bearing: The movable bearing is changed from the lower seat plate in the flat bearing to the arc panel, which can improve its slip and rotation performance, used for spans less than 20 meters of public and railroad bridges. In the seat between the plate plus pins into a fixed bearing.

④ Rocking shaft bearing: With cast steel rocking shaft and the upper and lower seat plate composition of the movable bearing, used for medium span beam bridge.

⑤ Hinge type fixed bearing: Composed of cast steel upper and lower pendulums, with a pendulum card embedded between the two pendulums to control lateral sliding. Is used for large span girder bridge fixed bearing.

⑥ Hinged roller bearing: In the hinged fixed bearing under the pendulum with forged steel roller and cast steel seat plate, the number and size of the roller according to the size of the support reaction force to determine. Commonly used in the large span beam bridge movable bearing.

⑦ Two-way movable bearing: It is composed of two layers of hinged roller bearings that are stacked on top of each other and can roll in both directions of orthogonality, and is used for large-width girder bridges.

Arrangement of bridge bearings

The arrangement of bridge bearing is mainly related to the structural form of the bridge. Generally, the following basic principles need to be considered when arranging bearings:

- When the superstructure is a spatial structure, the bearing should be able to adapt to the deformation of the bridge along the bridge direction (X direction) and the transverse bridge direction (Y direction) at the same time;

- The bearing must be able to reliably transmit vertical and horizontal reaction forces;

- The bearing should make the longitudinal displacement, lateral displacement and longitudinal and lateral rotation angles caused by the deformation of the beam body as unconstrained as possible;

- Bridges must usually be provided with a fixed bearing on each beam body;

- When the bridge is located on the ramp, the fixed bearing should generally be set on the abutment in the downhill direction;

- When the bridge is located on a flat slope, the fixed bearing should be installed on the front abutment in the main driving direction;

- The fixed bearing should be set in a place with a large support reaction force;

- Several bearings on the same pier should have similar rotational stiffness;

- When the bearing subsidence of the continuous beam may occur, the possibility of making height adjustments should be considered.

In a word, the principle of arrangement of bridge bearings is not only to facilitate the transmission of bearing reaction force, but also to make the bearings fully adapt to the free deformation of the beam body.

Installation of bridge bearings

- Before the bearing is installed, the installation position of bearing should be measured and inspected. The installation plane of bearing should be parallel to the sliding plane or rolling plane of bearing, and the deviation of parallelism should not exceed 2‰.

- Bearing installation before the movable bearing top, bottom plate relative position to check.

- After the bearing is installed, the rolling and sliding planes should be horizontal, and the inclination with the theoretical plane should not be greater than 2‰. The center of the upper and lower plates of bearing is in response, and the deviation is not more than 2‰.

- In order to ensure the installation of the bearing flat, generally should be in the bearing bottom surface and title between the top surface of the mat stone, pounding 20 – 50mm thick dry hard non-shrinkage mortar bedding layer.

In order to ensure the construction quality of the bridge bearing, and the convenience of installation, adjustment, observation, and replacement of the bridge bearing regardless of the cast-in-place method or prefabricated beam method of construction, regardless of the type of bridge bearing installed, the top of the pier set support mat stone is necessary.

Maintenance of bridge bearings

Bearing in the use of years should be regular maintenance, these tasks include: steel surface painting, roller and rocking shaft rotating part of the regular scrubbing and lubricating oil, sliding bearing stainless steel surface scrubbing and check the bearing anchor bolts, etc. Only regular maintenance to ensure the normal working condition of the bearing.

Bridge bearing each time in maintenance and reinforcement must be carried out before the maintenance inspection work, these work content can not only ensure the normal work of the bridge bearing, but also ensure the normal use of the bridge.

The following is a brief introduction to the maintenance and inspection work of the bridge bearing:

- The bedding bearing linoleum whether there is aging fracture situation.

- Whether the steel plate sliding bearing and curved bearing of the rust phenomenon.

- Whether the swing column bearing is correctly positioned, whether the force is uniform.

- Whether the fixing bolts of the sliding basin rubber bearing are damaged or the nuts are loose.

- Whether the rubber bearing has aging deformation.

- Whether the movable support is flexible and whether the actual displacement is correct.

- There is also to see if the waterproof device and its drainage device in the downturn are leaking. If this is the case for a long time, the bearing will be rusted and corroded, so the normal use of the bridge bearing cannot be guaranteed.

If you are still unclear about the details of the bridge bearing, please feel free to contact Boomarine. As a professional marine equipment supplier, we can provide you with a full range of solutions.