Table of Contents

1. Introduction

Mooring bollards are fixtures used in maritime transportation and shipping to secure ships and boats to a dock or quay. They are typically made of metal, such as cast iron or steel, and are designed to withstand the forces of mooring, including the weight of the vessel, wind, and waves.

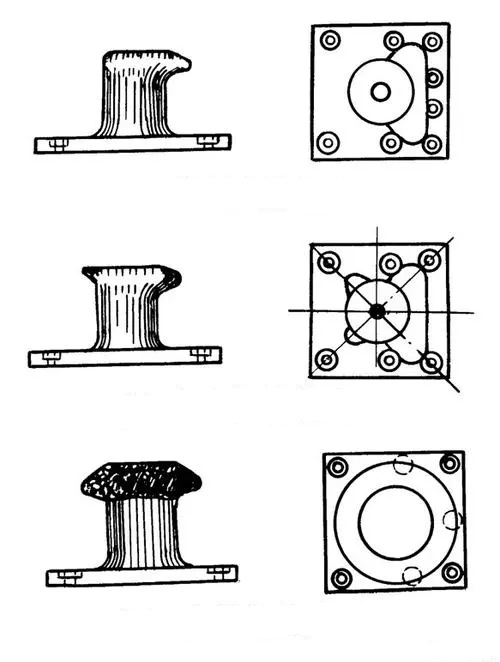

Bollards come in various shapes and sizes, with the most common being the traditional “T” shaped bollards. These bollards have a vertical post that is mounted onto a base or foundation, which is then secured to the dock or quay. The top of the post has a horizontal crossbar, which is used to secure the vessel’s mooring ropes.

Mooring bollards are typically spaced evenly along the dock or quay to allow for multiple vessels to be secured at once. They are also designed to be easily accessible to crew members, who can quickly attach or detach mooring lines as needed.

Overall, mooring bollards play an important role in the safety and efficiency of maritime transportation and shipping, ensuring that vessels remain secure and stationary while docked.

2. Importance of mooring bollards in the maritime industry

Mooring bollards are essential fixtures in the maritime industry, as they play a critical role in ensuring the safe and efficient operation of vessels when they are docked. Here are some of the key reasons why mooring bollards are so important:

- Safety: When a vessel is moored, it is held in place by the tension in the mooring lines. Mooring bollards are designed to handle the high loads and forces that are generated by these lines, helping to ensure that the vessel remains securely anchored to the dock or quay. This is crucial for preventing accidents or damage to the vessel, the dock, or nearby structures.

- Efficiency: Mooring bollards are strategically placed along the dock or quay to allow for multiple vessels to be secured at once. This helps to maximize the use of available dock space and minimize delays or bottlenecks in the loading and unloading of cargo. Additionally, bollards are designed to be easily accessible to crew members, who can quickly attach or detach mooring lines as needed, speeding up the mooring process.

- Durability: Mooring bollards are typically made of high-strength materials, such as cast iron or steel, which are resistant to corrosion and can withstand harsh marine environments. This makes them a reliable and long-lasting investment for port operators and shipowners alike.

In summary, mooring bollards are critical components of the maritime industry, providing essential safety and efficiency benefits to vessels and ports alike.

3. Design and Installation of Mooring Bollards

A. Design considerations for mooring bollards:

- Load capacity: The load capacity of the bollard must be carefully calculated to ensure that it can safely withstand the forces generated by the mooring lines of the vessel it will be used to secure. This will depend on factors such as the size and weight of the vessel, the prevailing weather conditions, and the type and strength of the mooring lines.

- Location: The location of the bollard should be carefully chosen to ensure that it is easily accessible for crew members to attach and detach mooring lines, while also providing enough space for multiple vessels to be moored simultaneously.

- Materials: Bollards are typically made of durable materials such as cast iron, steel, or stainless steel, which are resistant to corrosion and can withstand harsh marine environments.

- Design: The design of the bollard should be carefully considered to ensure that it is both functional and aesthetically pleasing. Some common bollard designs include the traditional “T” shape, as well as more decorative designs that can be customized to fit the specific needs of the port or vessel owner.

B. Installation process for mooring bollards:

- Site preparation: The area where the bollards will be installed must be cleared of any debris or obstructions, and the ground should be leveled and compacted to provide a stable foundation.

- Foundation installation: The bollard foundation should be carefully designed to ensure that it can support the load capacity of the bollard. This may involve pouring a concrete foundation, or using pre-cast or pre-fabricated foundations.

- Bollard installation: Once the foundation is in place, the bollard can be installed using bolts or anchor rods. The bollard should be securely attached to the foundation to ensure that it will not become dislodged during use.

- Testing: After installation, the bollards should be load tested to ensure that they can safely withstand the forces generated by the mooring lines of the vessel.

C. Maintenance and inspection of mooring bollards:

- Regular inspections: Bollards should be inspected regularly to ensure that they are in good condition and can safely support the loads they are designed to withstand.

- Cleaning and lubrication: Bollards should be cleaned regularly to remove any dirt, debris, or salt buildup that could cause corrosion or other damage. They should also be lubricated periodically to ensure that they remain easy to use.

- Repairs and replacement: If a bollard is found to be damaged or worn out, it should be repaired or replaced as soon as possible to ensure that it remains safe and functional. Regular maintenance and prompt repairs can help to extend the lifespan of mooring bollards and ensure that they continue to provide reliable service for many years.

4. Safety Considerations

A. Importance of safety when using mooring bollards:

Safety is of paramount importance in the use of mooring bollards. When not used properly, mooring bollards can cause accidents or damage to the vessel, dock or nearby structures, leading to severe consequences. This can put the lives of the crew, passengers, and other personnel at risk. Therefore, proper safety considerations are crucial when using mooring bollards.

B. Safety features of mooring bollards:

Load capacity: Mooring bollards are designed to withstand high loads generated by the mooring lines of the vessel. They are manufactured to strict standards and regulations to ensure that they can handle the forces generated by the vessel in a safe and reliable manner.

- Visibility: Mooring bollards are usually painted in bright colors, with reflective markings or lighting, making them highly visible to crew members, especially in low-light conditions.

- Design: Mooring bollards are designed to minimize the risk of injury to crew members. They usually have smooth surfaces, with no sharp edges or protrusions that could cause harm.

- Securing mechanisms: Mooring bollards have different securing mechanisms, including locking pins, locking collars, or cam mechanisms, to ensure that mooring lines are securely attached and will not come loose.

C. Proper use of mooring bollards:

- Training: Crew members should be properly trained in the use of mooring bollards, including how to attach and detach mooring lines safely.

- Inspection: Mooring bollards should be regularly inspected to ensure that they are in good condition and can safely support the loads they are designed to withstand.

- Use of appropriate lines: Crew members should use appropriate mooring lines that match the load capacity of the bollard, and they should be secured properly to prevent any sudden releases or failures.

- Awareness of surroundings: Crew members should always be aware of their surroundings when using mooring bollards. They should avoid standing between the vessel and the bollard or between the bollard and the dock, to avoid getting caught or crushed.

Overall, the safe use of mooring bollards requires proper training, regular inspection, and appropriate use of equipment to minimize the risk of accidents and ensure the safety of crew members and vessels.

Conclusion

In summary, mooring bollards are an essential component of the maritime industry. They are critical for securing vessels to docks, quays, and piers, allowing for safe and efficient loading and unloading of cargo and passengers. Mooring bollards are designed and installed to withstand the forces generated by the mooring lines of the vessel, and they must be properly maintained to ensure their safe and reliable use. Safety considerations are of utmost importance in the use of mooring bollards, including proper training of crew members and regular inspections of the equipment.

Mooring bollards have been used in the maritime industry for centuries and have evolved to meet the changing needs of the industry. They are an integral part of the infrastructure of ports and harbors worldwide, providing a safe and reliable means of securing vessels to docks and piers. The proper design, installation, and maintenance of mooring bollards are crucial to ensure their long-term effectiveness, and their safety features play a critical role in the prevention of accidents and damage to vessels, docks, and other structures. Overall, mooring bollards have a significant impact on the maritime industry, and their continued use and development will be essential for the future of global trade and transportation.